Patents

Literature

49 results about "Materials science and technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

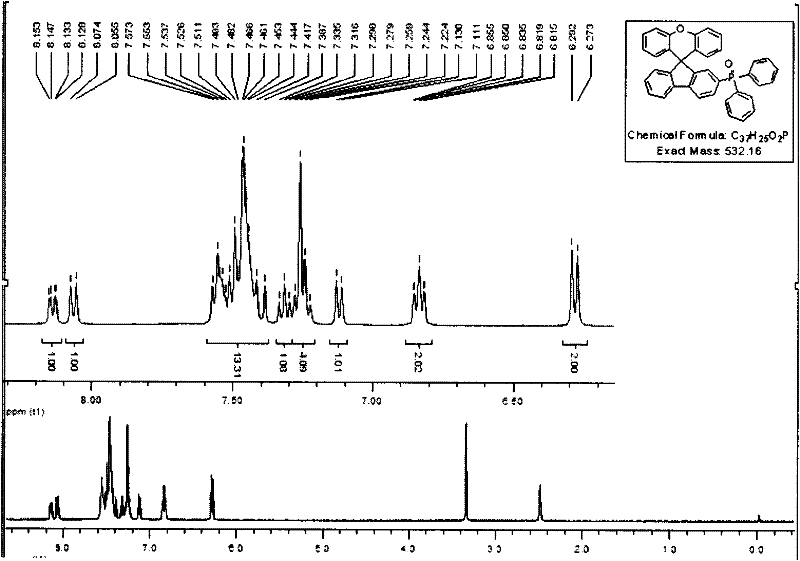

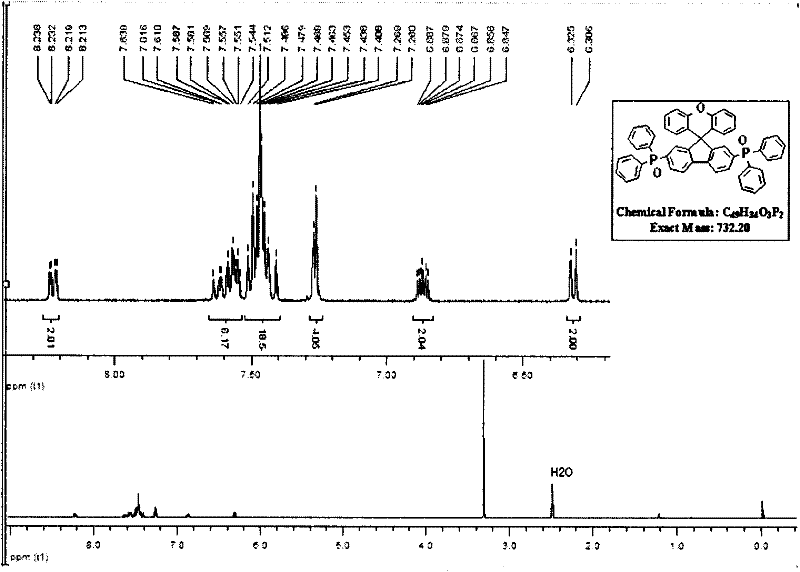

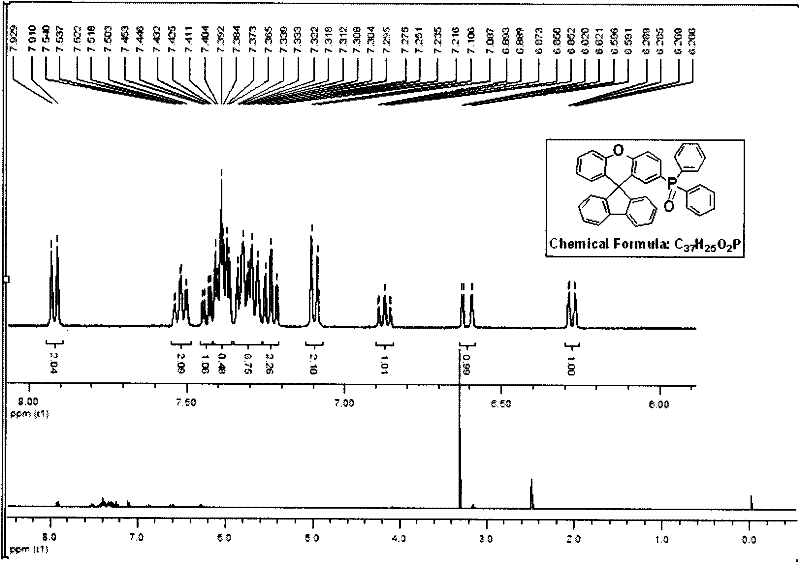

Spirofluorene xanthene phosphine oxide electro-phosphorescent main materials and synthesis and application methods thereof

InactiveCN102229623ALow costHigh triplet energyGroup 5/15 element organic compoundsSolid-state devicesOrganic solar cellField-effect transistor

The invention relates to spirofluorene xanthene phosphine oxide electro-phosphorescent main materials and synthesis and application methods thereof, belongs to the field of photoelectric material science and technology, and in particular relates to four spirofluorene xanthene organic phosphine oxide materials and application of the materials in the field of organic electronics such as organic electroluminescent materials, organic solar cells, organic field-effect tubes, dye laser, organic nonlinear optical materials, fluorescent probes and the like. The series of materials are obtained by introducing diphenyl phosphine oxide groups to the 2nd site, the 2nd and 7th sites, the 2nd' site and the 2nd' and 7th' sites of spirofluorene xanthene respectively. The series of compounds have good charge transfer performance, thermal stability and high triplet energy level (ET=-2.86eV), and can be used as main materials and applied in phosphorescent devices. When the series of compounds are applied in the organic electro-phosphorescent devices, the maximum external quantum efficiency is 10.78 percent and the maximum brightness is 8,582cd / m<2> in the blue phosphorescent device; and in the green phosphorescent device, the maximum external quantum efficiency is 19.1 percent, and the maximum brightness is 16,943cd / m<2>.

Owner:NANJING FANGYUAN GLOBAL DISPLAY TECH

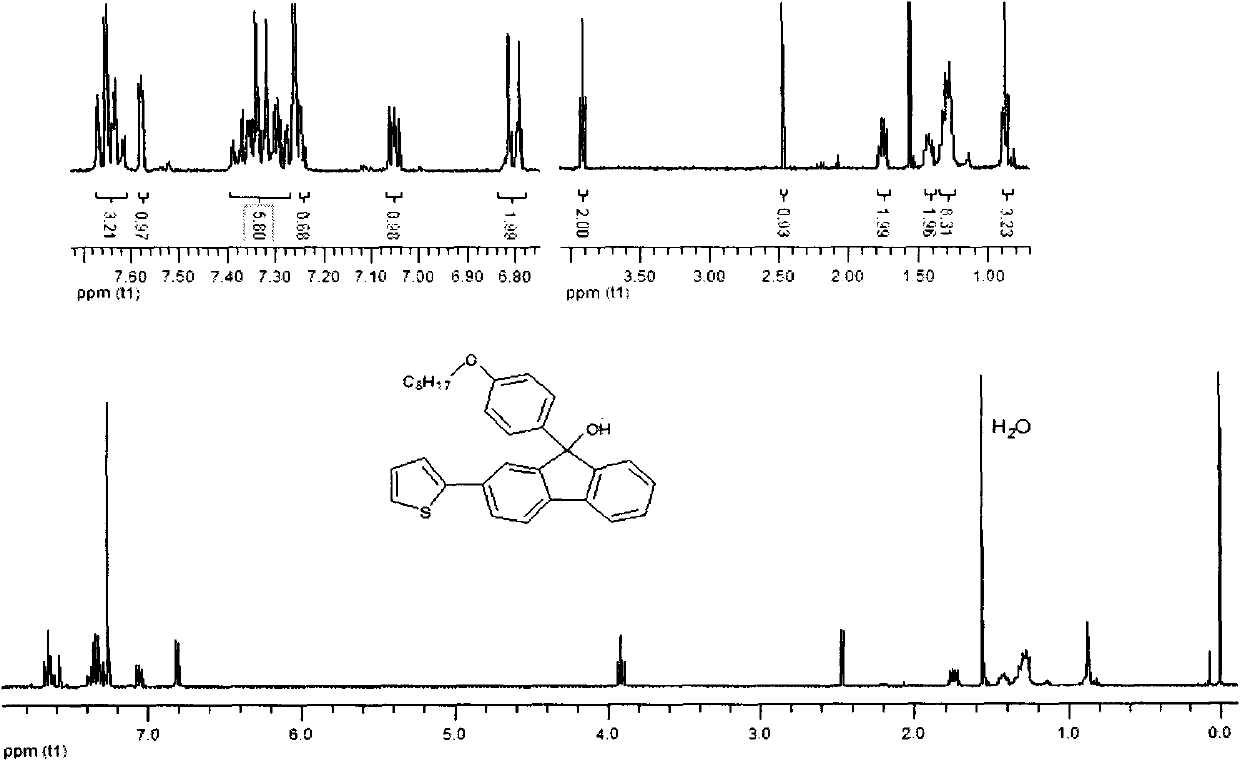

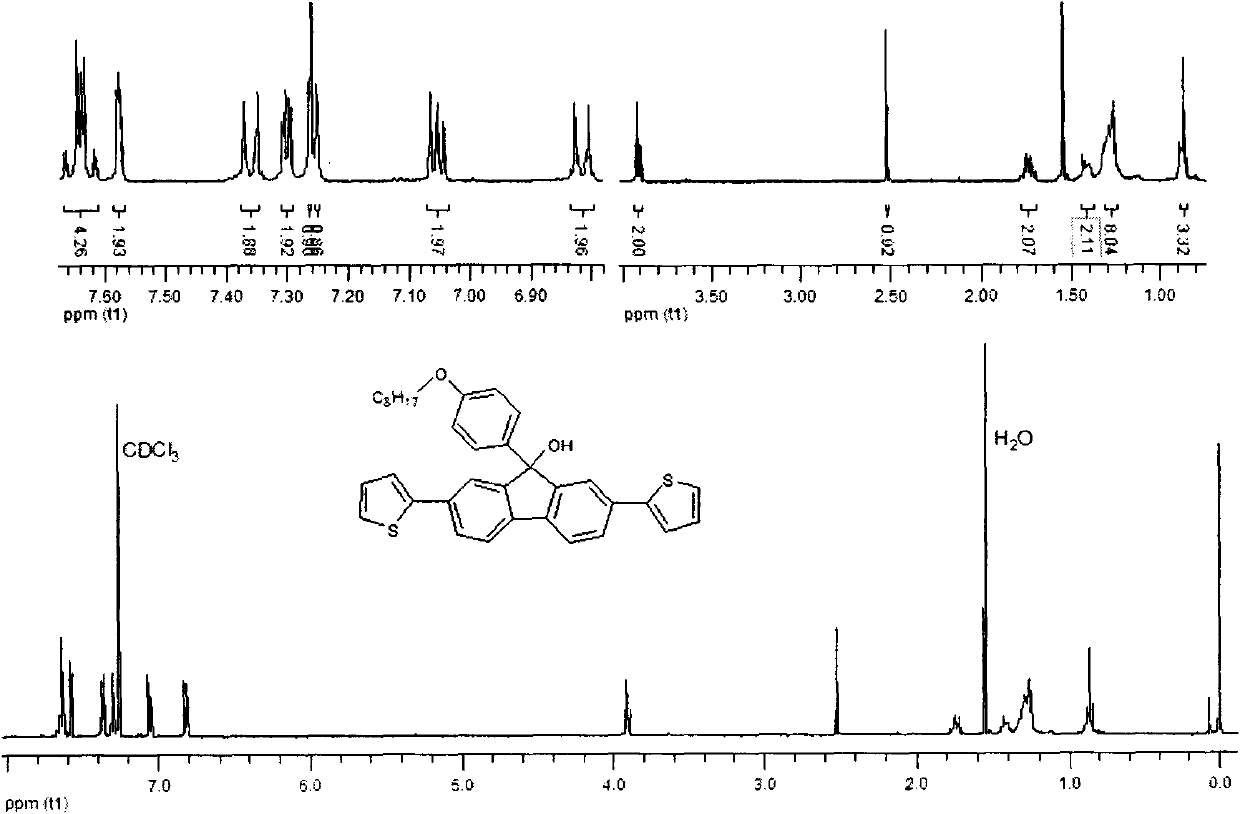

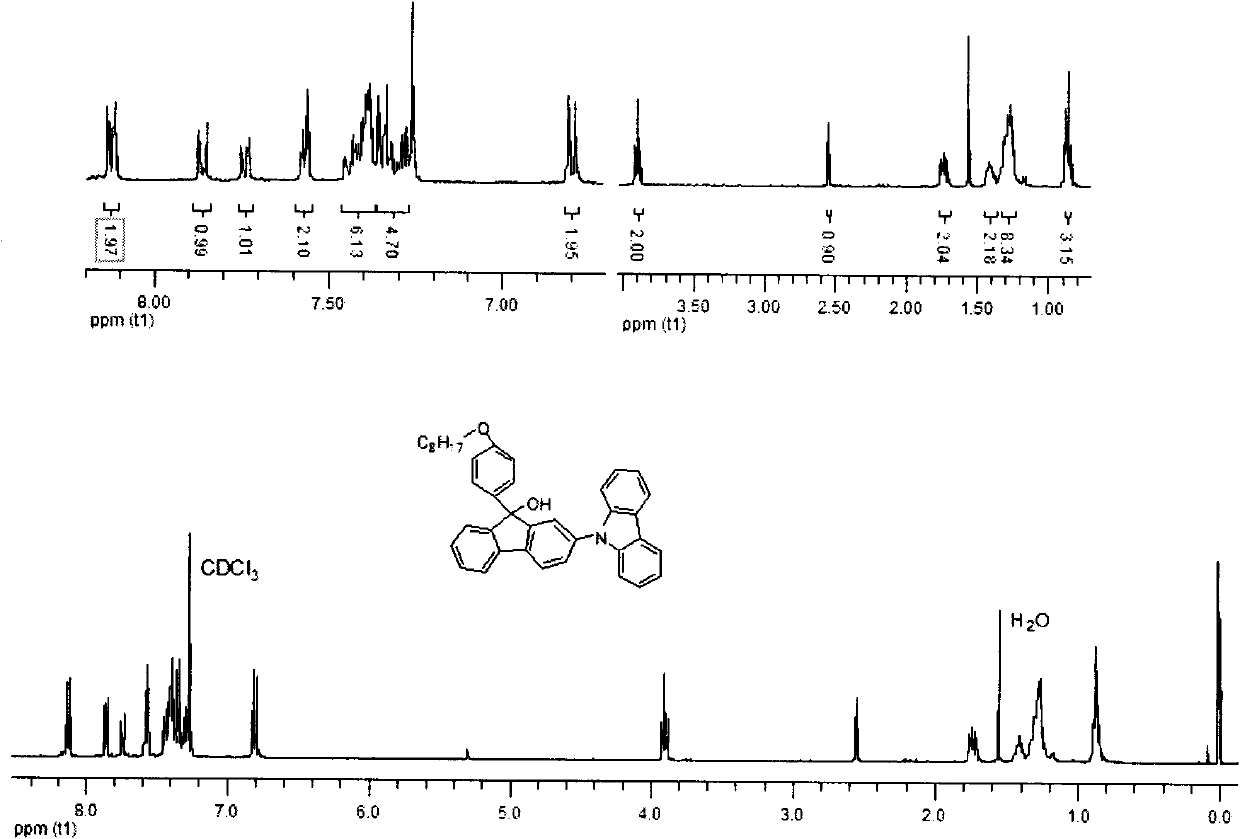

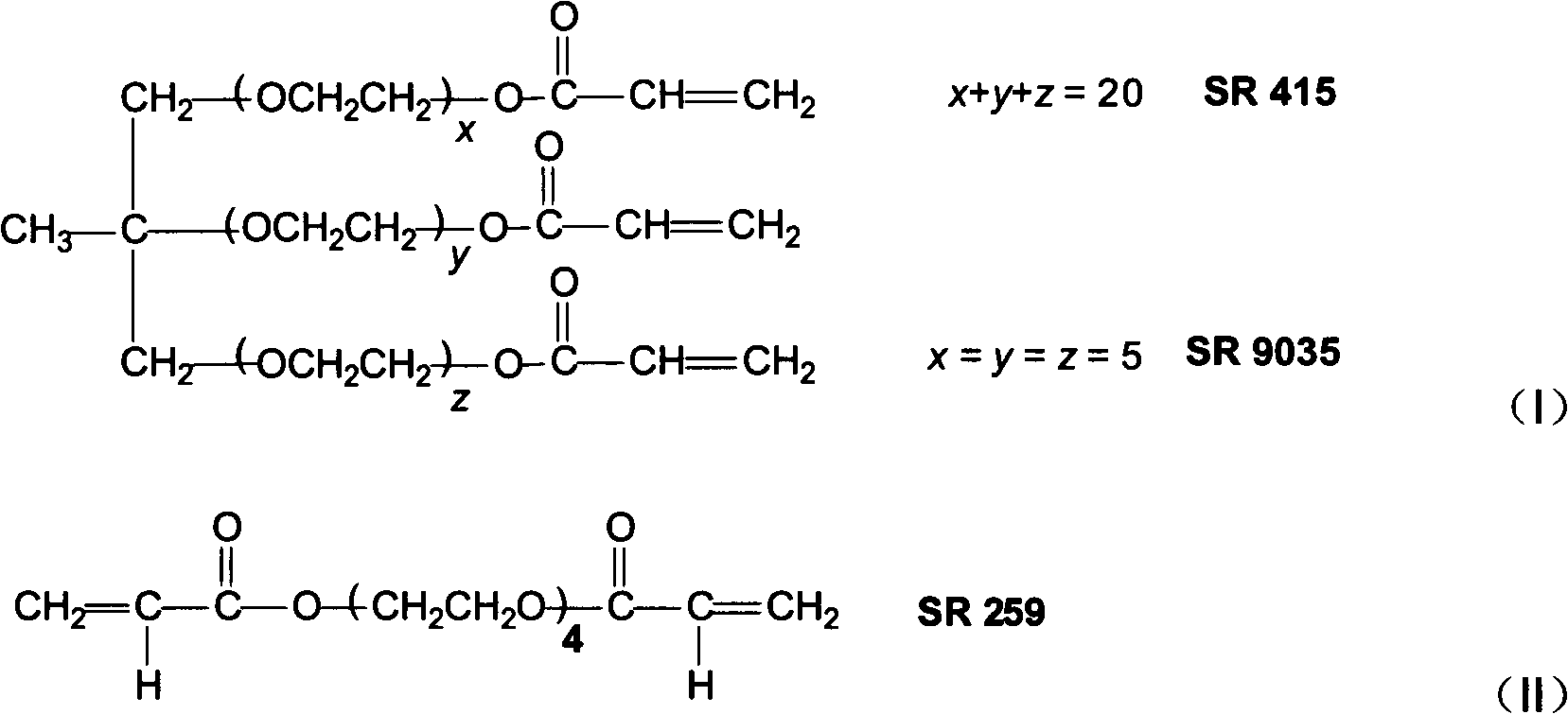

Conjugation interrupted hyperbranched polymer semiconductor optoelectronic material and its preparation and application method

InactiveCN102295758AHigh yieldSustainableSolid-state devicesSemiconductor/solid-state device manufacturingOrganic memorySolar cell

Conjugation interrupted polymer semiconductor materials and their preparation and application methods belong to the field of organic photoelectric materials technology, and have potential important applications in the fields of light-emitting diodes, solar cells, phosphorescent host materials, organic electrical storage materials, porous materials, and gas sensing. . The conjugation interrupted polymer semiconductor material of the present invention has the following structure: the material has the advantages of high stability and simple synthesis route. This type of conjugation interrupted hyperbranched polymer semiconductor photoelectric material is prepared by Friedel-Crafts polymerization catalyzed by boron trifluoride ether at room temperature; the raw material is cheap, the operation is simple, the preparation is at normal temperature, and the yield is high.

Owner:NANJING UNIV OF POSTS & TELECOMM

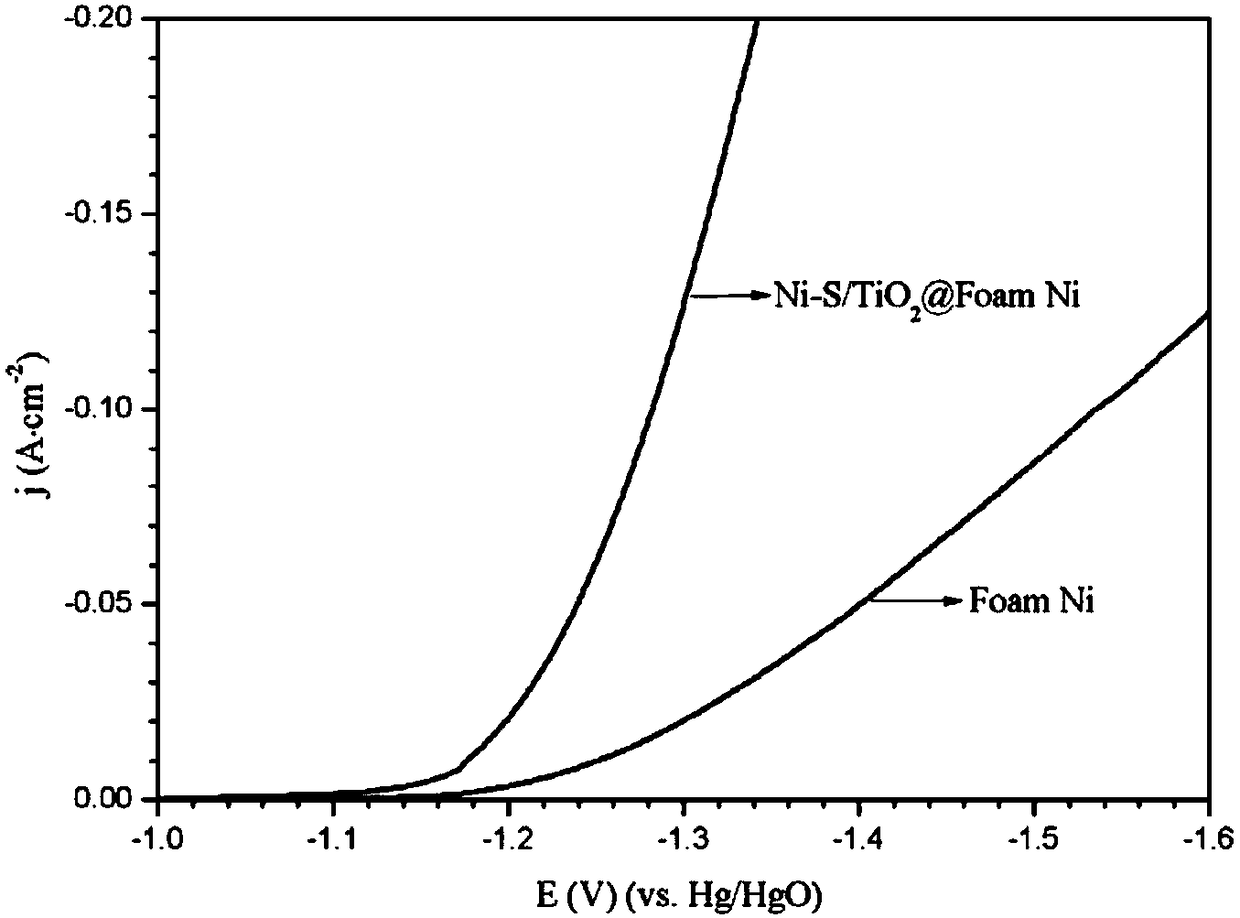

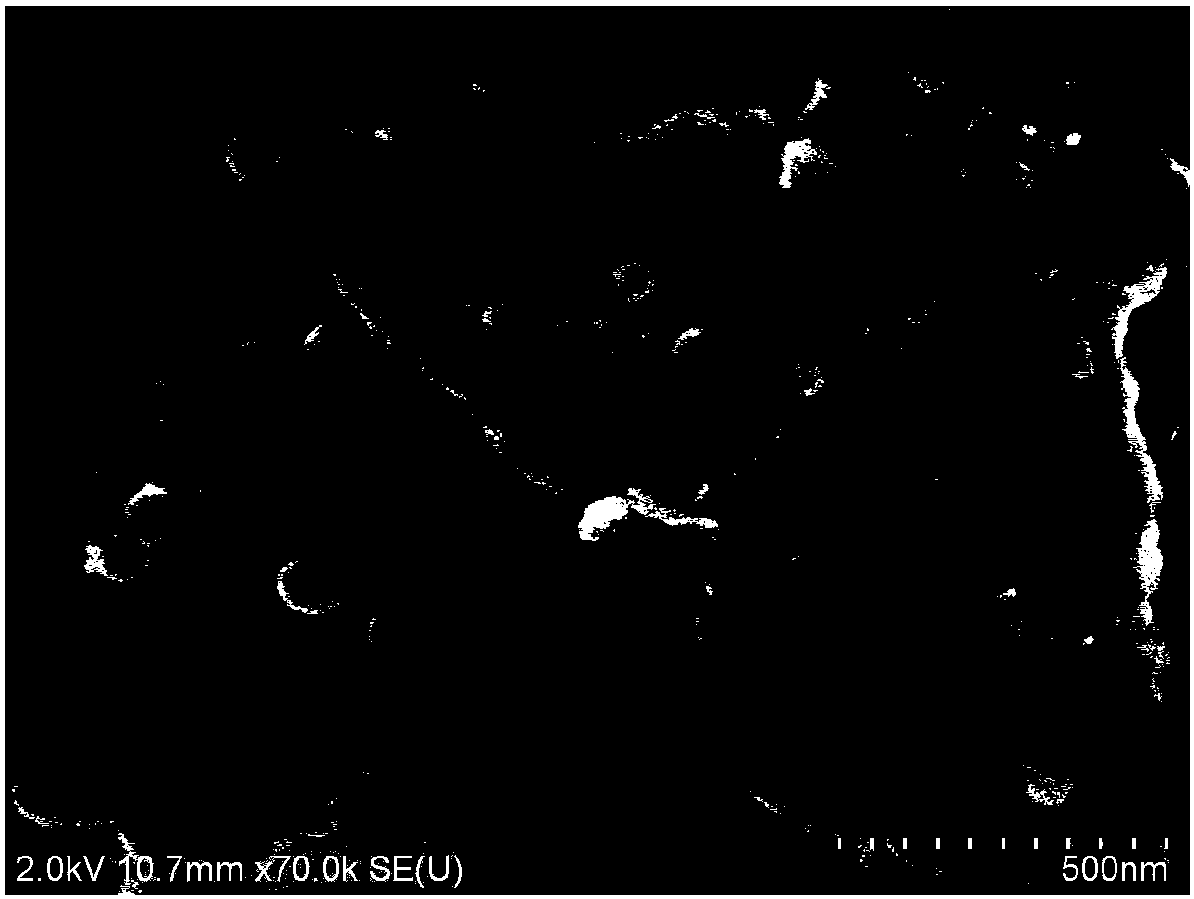

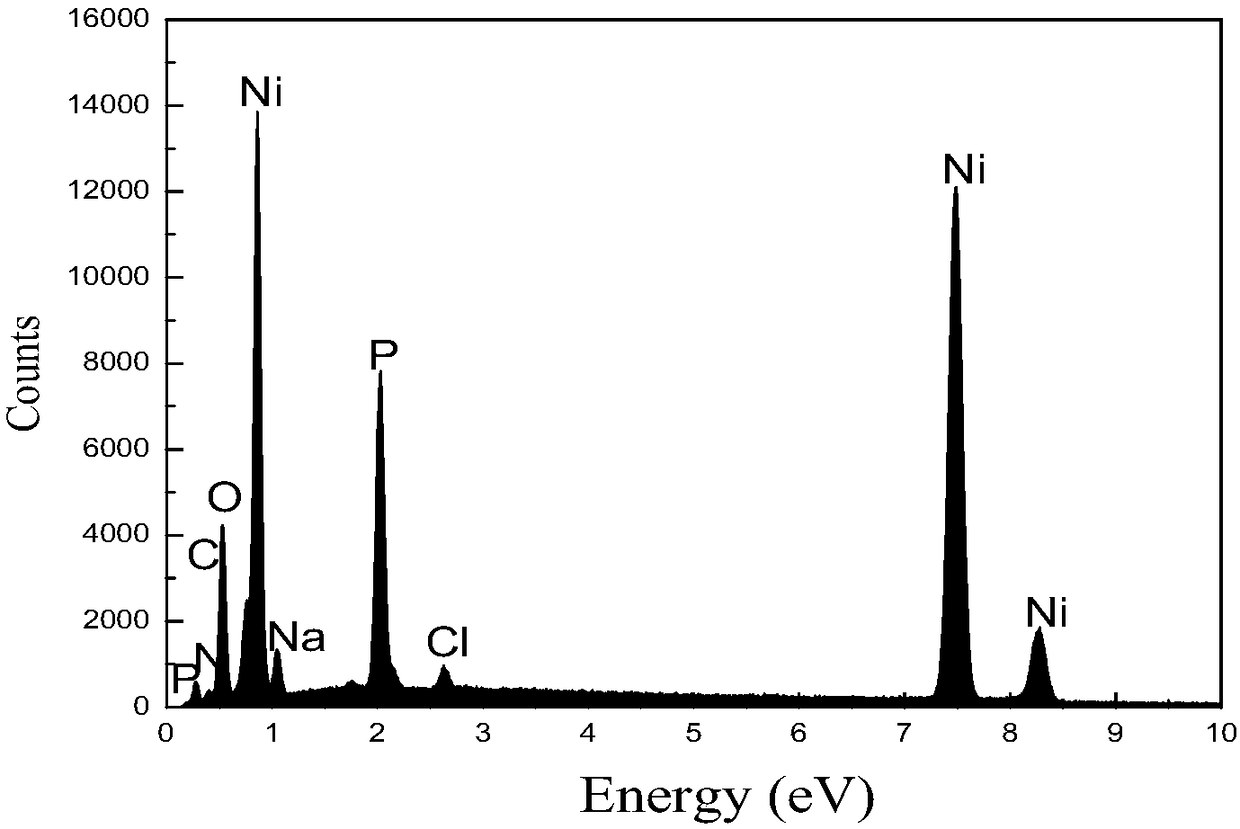

Porous Ni-S/TiO2 composite hydrogen evolution electrode and preparation method thereof

InactiveCN108070878ALarge specific surface areaExcellent hydrogen evolution catalytic performanceElectrolytic coatingsElectrode shape/formsMaterials science and technologyNickel

The invention relates to a porous Ni-S / TiO2 composite hydrogen evolution electrode and a preparation method thereof, and belongs to the field of the material science and technology and the field of electro-catalysis hydrogen production. According to the electrode, three-dimensional foamed nickel is adopted as a carrier to provide a porous structure, a nickel-sulfur plating layer is adopted as a surface active layer, TiO2 is doped in the nickel-sulfur plating layer in a composite manner through a composite electrodeposition method, and the foamed nickel based Ni-S / TiO2 composite hydrogen evolution electrode with the porous structure is formed. The composite electrodeposition method is adopted, and nickel-sulfur plating layer deposition is carried out on the surface of the three-dimensionalfoamed nickel. Meanwhile, in the electrodeposition process, the nanoscale TiO2 in composite plating liquid is doped in the nickel-sulfur plating layer through magnetic stirring. The prepared hydrogenevolution electrode has the advantages of being low in overpotential, high in electrode stability and the like, the preparation process is simple, cost is low, and the electrode is suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Phosphorus-containing compound, and preparation method and application thereof

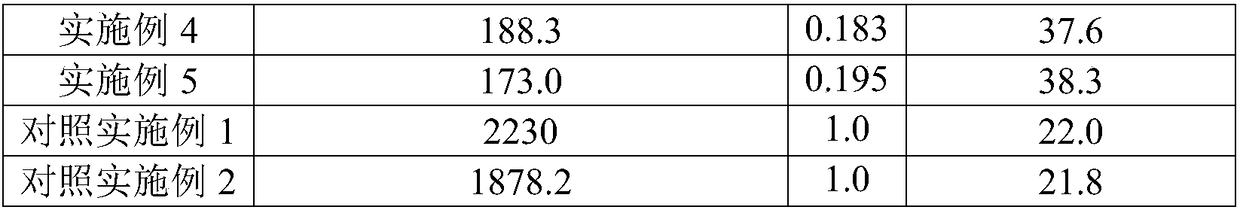

ActiveCN108499585AWeak crystallinityIncrease the rate of hydrogen productionPhysical/chemical process catalystsCell electrodesPhotocatalytic reactionNon noble metal

The invention discloses a phosphorus-containing compound, and a preparation method and an application thereof, and belongs to the fields of material science and technology and chemistry. The phosphorus-containing compound is prepared from cheap raw materials through the simple method; the method is essentially characterized in that the compound is prepared from metal ions and a phosphorus source under the illumination condition of a photoactive material; and the temperature in the prior art is more than 100 DEG C, and the method in the invention is a normal temperature synthesis process, so the obtained compound has a weak crystallization degree. The phosphorus-containing compound has a high photocatalytic activity as a conventional catalyst and a photocatalytic reaction cocatalyst, and achieves a high hydrogen production rate for a photocatalytic hydrogen production reaction. The method and the phosphorus-containing compound can be used for producing an electrode and producing a battery, so the production cost of the electrode and the battery is reduced, the preparation method is simplified, and the obtained electrode is a non-noble metal catalyst, and has the advantages of low cost, low overpotential, high stability and certain industrial application values.

Owner:JIANGNAN UNIV

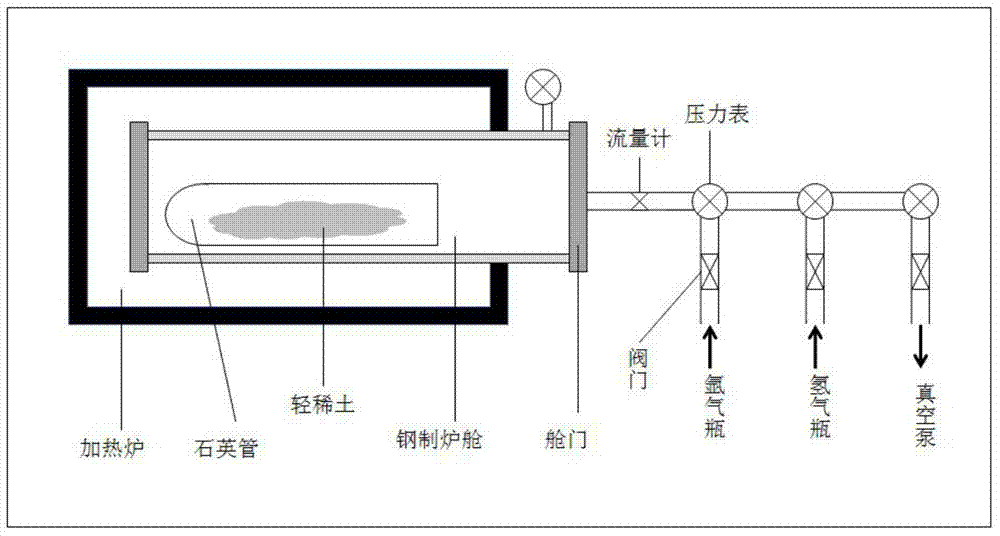

Method for preparing light rare earth hydride by high-temperature direct method

ActiveCN104291270ANo harmImprove manufacturing levelTransition element hydridesHydrogen pressureEvaporation

The invention belongs to the field of material science and technology and specifically relates to a method for preparing a light rare earth hydride by a high-temperature direct method. The method comprises the following main implementation steps: placing light rare earth with purity being greater than 99% and particle size being 2-15mm into a quartz glass test tube under the inert gas protection, removing air in a boiler room by the use of inert gas, closing an air evaporation valve, rapidly heating the boiler room at the heating rate of 2-20 DEG C / min until heating to 300-1000 DEG C, controlling inflow of hydrogen to 200-10,000 ml / min, and keeping the temperature and continuously reacting until a hydrogen pressure gauge and pressure in a heating reaction furnace are completely balanced, so as to obtain the required light rare earth hydride and corresponding light rare earth hydride powder. Purity of the light rare earth hydride prepared by the above method is 97-99.99%, and conversion rate of the light rare earth hydride powder is 97-99.99%. Thus, the hydride preparation purity problem in an industrial preparation technology is solved. The method is safe, reliable and is pollution-free, and is of great significance for industrialized and large-scale production of the light rare earth hydride.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Preparation method of liquid crystal microcapsules used for textile printing

ActiveCN108049211AApplicable requirementsHigh transparencyDyeing processMicroballoon preparationTextile printerOrganic solvent

The invention discloses a preparation method of liquid crystal microcapsules used for textile printing, and belongs to the technical fields of fine chemical engineering and material science and technology. A synthetic polymeric compound is adopted to replace natural polymer. A polymeric compound which is well compatible to textiles is selected and is taken as a shell material, and the structure ofthe shell material is adjusted to prepare crystal microcapsules suitable for textiles. The method is high in yield and free of organic solvents, and an initiator isn't required in a coating process of microcapsules. The wall material of the liquid crystal microcapsules is good in transparency. The liquid crystal microcapsules are bright-coloured, are controllable in structure, and are suitable for meeting the textile requirement.

Owner:JIANGNAN UNIV

Application of lithium-type molecular sieve

InactiveCN106299528AUse impactEasy to remove waterWaste accumulators reclaimingBattery recyclingLithium-ion batteryMaterials science and technology

The invention discloses application of a lithium-type molecular sieve in water removal, sodium removal and hydrogen fluoride removal treatment on a non aqueous electrolyte. The lithium-type molecular sieve is a full-lithium-type zeolite molecular sieve (the silica-aluminum ratio is 1:(0.9-1.1), and the lithium content exceeds 99.5%), and the full-lithium-type zeolite molecular sieve is produced by China Shipbuilding Industry Corporation 712 Research Institute and Suzhou Li'ang New Material Limited Company which are entrusted by Suzhou Simeite Surface Material Science and Technology Ltd. and has the type of LXO199 / LXO280. The lithium-type molecular sieve can directly conduct water removal, sodium removal and hydrogen fluoride removal on the non aqueous electrolyte by serving as a packaging reagent, be mixed with an electrode material to be prepared into an electrode to control the water content of an assembled lithium ion battery and effectively remove hydrogen fluoride generated by the lithium battery in the charging and discharging process.

Owner:SUZHOU SMART ADVANCED COATING TECH CO LTD

Method for preparing magnesia crystal by using temperature control arc furnace

InactiveCN1664176AIncrease productionQuality improvementPolycrystalline material growthFrom frozen solutionsFurnace temperatureTemperature control

The invention relates to a method for preparing the magnesia crystal by the temperature-controlling arc furnace, which belongs to the material scientific and technical field. The method uses the arc furnace published by (an arc furnace for preparing magnesia crystal), uses the data from the temperature-sensitive device and the furnace temperature state which is computed by the presetted thermal field equation as the criterion to arc welding and cooling, and forms the thermal field avails to crystal growth through the copulation of the arc and cooling device. The invention can increase the yield and quality of the magnesia crystal and can be used for growing another high temperature crystal.

Owner:LIAONING ZHONGDA SUPERCONDUCTING MATERIAL

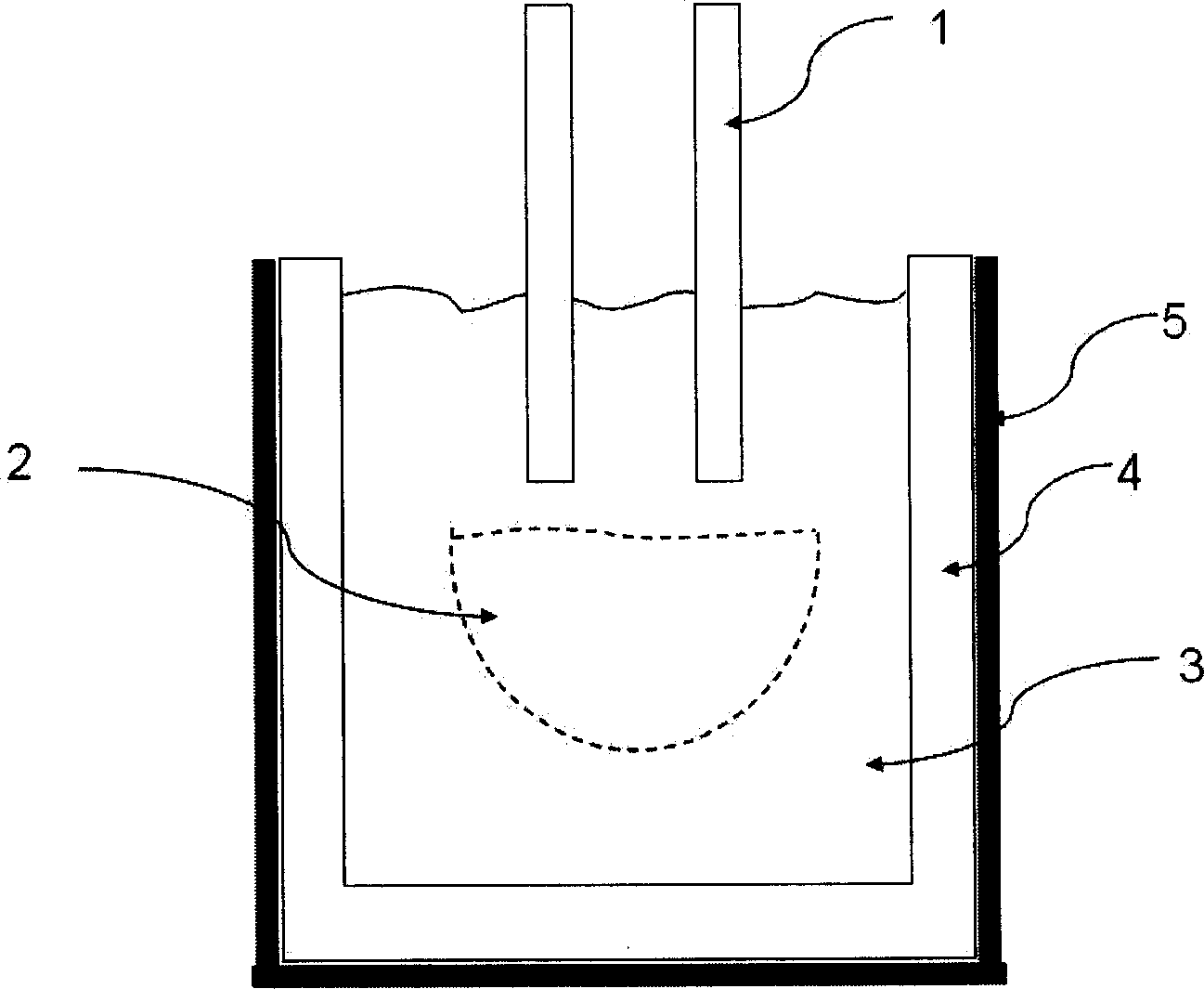

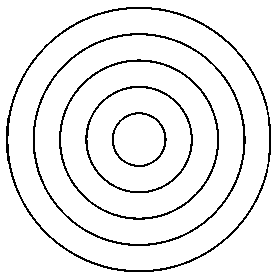

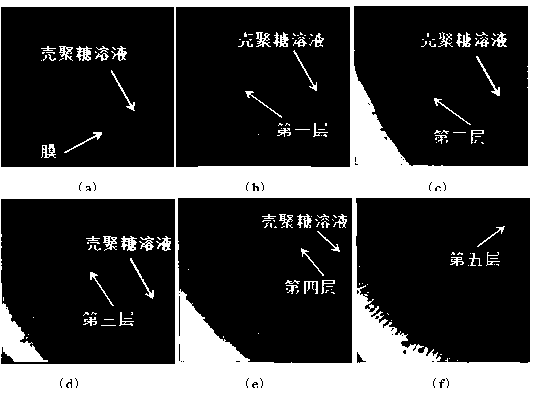

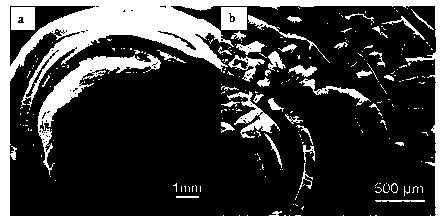

Chitosan multilayered gel balls and preparation method thereof

The invention discloses chitosan multilayered gel balls and a preparation method thereof, and belongs to the field of material science and technology. The preparation method comprises the following steps: dripping a chitosan acid solution into a sodium alginate solution while completely soaking chitosan drop into the sodium alginate solution; soaking a mixture into a NaOH solution after standing and washing, so as to obtain chitosan gel balls; repeatedly soaking the chitosan gel balls into deionized water and a NaOH solution, so as to obtain the chitosan multilayered gel balls. The chitosan multilayer gel balls with different layer quantities and different layer thicknesses can be obtained by controlling the concentration of the NaOH solution and soaking time. The preparation method disclosed by the invention has the advantages of no pollution, simple reaction instrument, temperate reaction conditions and the like, and is a method for inducing the inside of a soft material to generate an accurate and complex structure through external stimulation. The chitosan multilayered gel balls prepared by the invention have the advantages of complex internal structure and large surface area, and can be applied to various fields as a reaction template of nanometer particles.

Owner:WUHAN UNIV

Titanium alloy forge piece preparation method

ActiveCN112108606AReduce manufacturing costIncrease manufacturing costMetal-working apparatusFurnace typesWire cuttingWater jet cutter

The invention belongs to the field of material science and technology processing and manufacturing, and relates to a titanium alloy forge piece preparation method. According to the method, firstly, aqualified cast ingot is subjected to one-to-two-heat two-upsetting two-drawing deformation at 1000 DEG C to 1150 DEG C to obtain a primary square billet; then the primary square billet is subjected totwo-heat short-process rolling at 30 DEG C to 60 DEG C below a phase transformation point to obtain a finished plate with a thickness of 110 mm; then by using a water jet cutter or through wire cut electrical discharge machining, blanking is carried out to directly obtain a balance elbow intermediate billet, then the balance elbow intermediate billet is bent and die-forged at 35 DEG C to 40 DEG Cbelow the phase transformation point to obtain a balance elbow die forging; and finally, heat treatment is carried out on the balance elbow die forging to obtain a balance elbow forge piece finishedproduct. According to the preparation method, a whole-process low-cost control thought is adopted, and large-deformation short-process rolling processes of two-phase regions at different temperaturesare introduced, so that purposes of quickly refining and homogenizing a structure are achieved, the manufacturing cost of a forge piece is reduced, and the fatigue performance of the forge piece is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

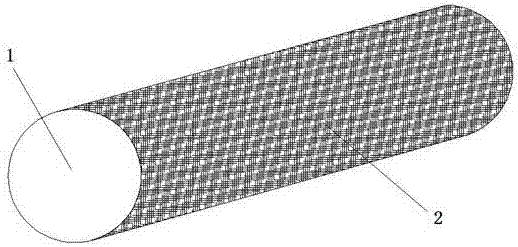

Preparation method of carbon fibre reinforced cast nylon composite material

The present invention belongs to the field of material science and technology, and includes the following steps: pretreatment of carbon fibre, soaking carbon fibre to be treated in nitric acid solution, then using sodium hydroxide solution and water to fully wash until its pH value is not acidic, uniformly mixing the treated carbon fibre with caprolactam monomer, placing the obtained mixture into a container, heating and making the material melt, evacuating said container and dehydrating, adding catalyst soldium hydroxide, heating and melting, adding activating agent tolylene diisocyanate, and pouring the above-mentioned material into mould, heat-insulating and demoulding so as to obtain the invented product with excellent mechanical properties of higher tensile-strength and bending strength and raised frictional property.

Owner:TSINGHUA UNIV

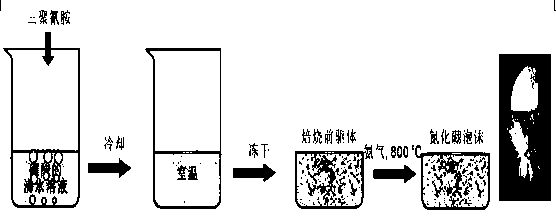

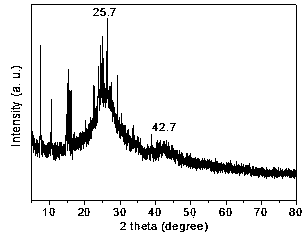

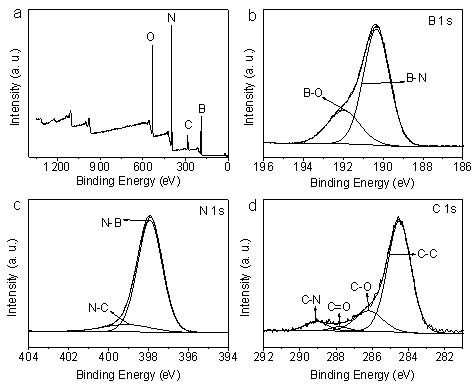

Preparation method and propane oxydehydrogenation application of rodlike hexagonal boron nitride foam

ActiveCN110668407AImprove performancePhysical/chemical process catalystsNitrogen compoundsPtru catalystHexagonal boron nitride

The invention discloses a preparation method and propane oxydehydrogenation application of rodlike hexagonal boron nitride foam, and relates to the fields of material science and technology and petrochemical engineering. The preparation method of the rodlike hexagonal boron nitride foam utilizes a hydrolysis polymerization reaction of melamine and boric acid. A dried precursor is reduced in ammonia gas to generate hexagonal boron nitride which is a white foam solid. The foam is prepared from rodlike hexagonal boron nitride having connected pores (with the size of about 100 nm). The pore structure is beneficial to gas circulation and diffusion, so the foam has good potential as a heterogeneous catalyst. The rodlike hexagonal boron nitride foam shows excellent propane dehydrogenation performance. The method has the advantages of simplicity, high yield, facilitation of large-scale industrial production, and remarkable economic and social benefits.

Owner:FUZHOU UNIV

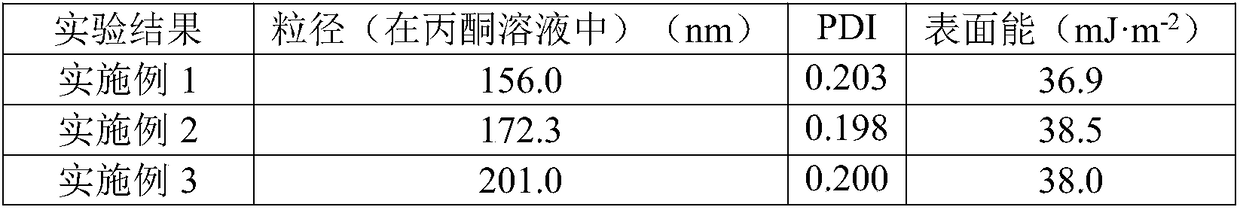

Preparation method of polylactic acid fiber pre-spinning colorant

ActiveCN108084412ASmall particle sizeNarrow distributionPigment addition to spinning solutionMonocomponent polyesters artificial filamentIn situ polymerizationHigh surface

The invention discloses a preparation method of a polylactic acid fiber pre-spinning colorant, and belongs to the technical field of fine chemical engineering and material science and technology. According to the preparation method provided by the invention, nano modified pigment is prepared by an in-situ polymerization method, and the nano modified pigment is used for pre-spinning coloring of polylactic acid fibers. The modified pigment prepared by the method has a small particle size, narrow distribution and a relatively high surface energy, wherein the particle size is about 200nm, the PDIis about 0.2, and the surface energy is about 38.5; and the modified pigment is similar to polylactic acid, and thus has good compatibility with a polylactic acid fiber spinning solution.

Owner:JIANGNAN UNIV

Wide temperature range antishock polystyrene material and its prepn process

The present invention relates to material science and technology, and is especially wide temperature range antishock polystyrene material and its preparation process. The antishock polystyrene material is prepared in a in-situ doping copolymerization or doping co-mixing process, and features the simultaneous introducing of RE alkoxide and elastic monomer or elastic polymer. By means of the coordination of RE metal ion in the RE alkoxide and the benzene ring in polystyrene, and the synergistic effect of the RE alkoxide and the benzene ring, C-C double bond, etc. in the elastic monomer or elastic polymer, polystyrene material with wide temperature range as well as raised rigidity, solvent resistance, heat stability, weather resistance, etc. is prepared.

Owner:FUJIAN NORMAL UNIV

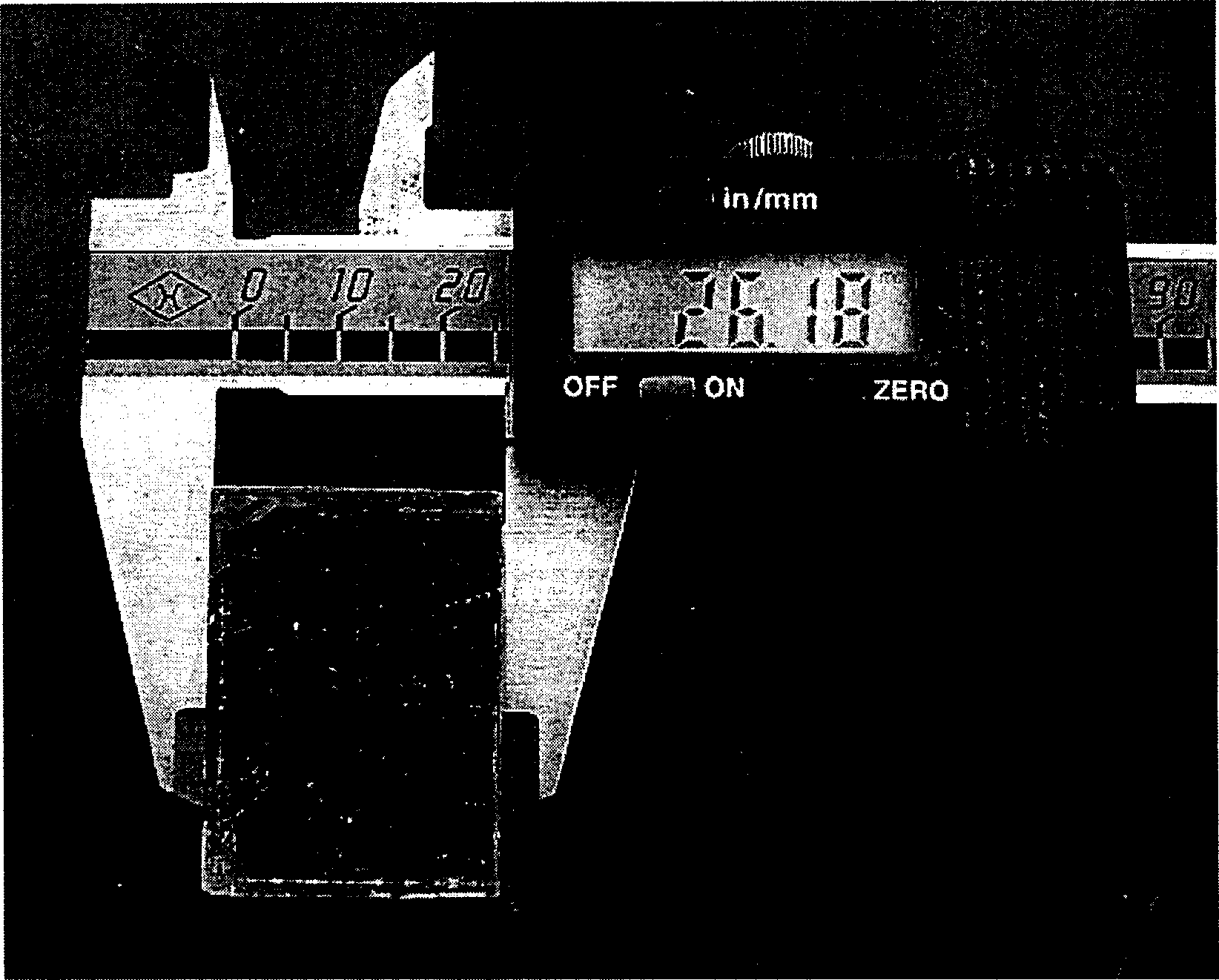

High-purity large-size silicon carbide single crystal and preparation process thereof

InactiveCN103757703AHigh densitySmall sizePolycrystalline material growthFrom frozen solutionsElectric arc furnaceCrystal structure

The invention discloses a high-purity large-size silicon carbide single crystal and a preparation process thereof, and belongs to the field of the material science and technology. The preparation process comprises the steps of taking high-purity SiC powder as the raw material, realizing rational grain composition of the SiC powder different in grain size and obtaining the maximum loading density, next, loading the SiC powder in an ultrahigh-power vertical electric arc furnace, carrying out static smelting at a high temperature and under high pressure, and then growing the high-purity large-size silicon carbide single crystal through recrystallization. The manufacturing method of the high-purity large-size silicon carbide single crystal has the advantages of simple process and low cost, and the prepared silicon carbide single crystal is high in purity (> 99.99%), large in size (greater than or equal to 25mm), colourless to light green and transparent, and has a 3C crystal structure. The preparation process is simple, low in cost, high in efficiency, and advantageous for popularization and application.

Owner:汪长安

Fluorescent powder for non-contact fluorescence temperature measurement and preparation method thereof

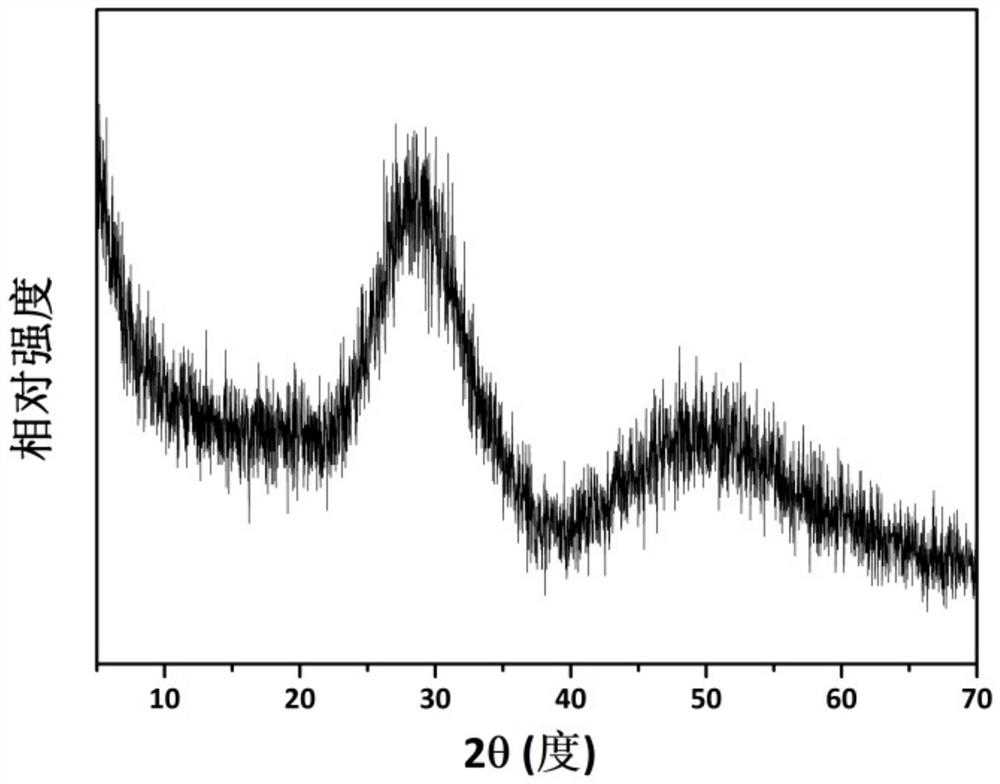

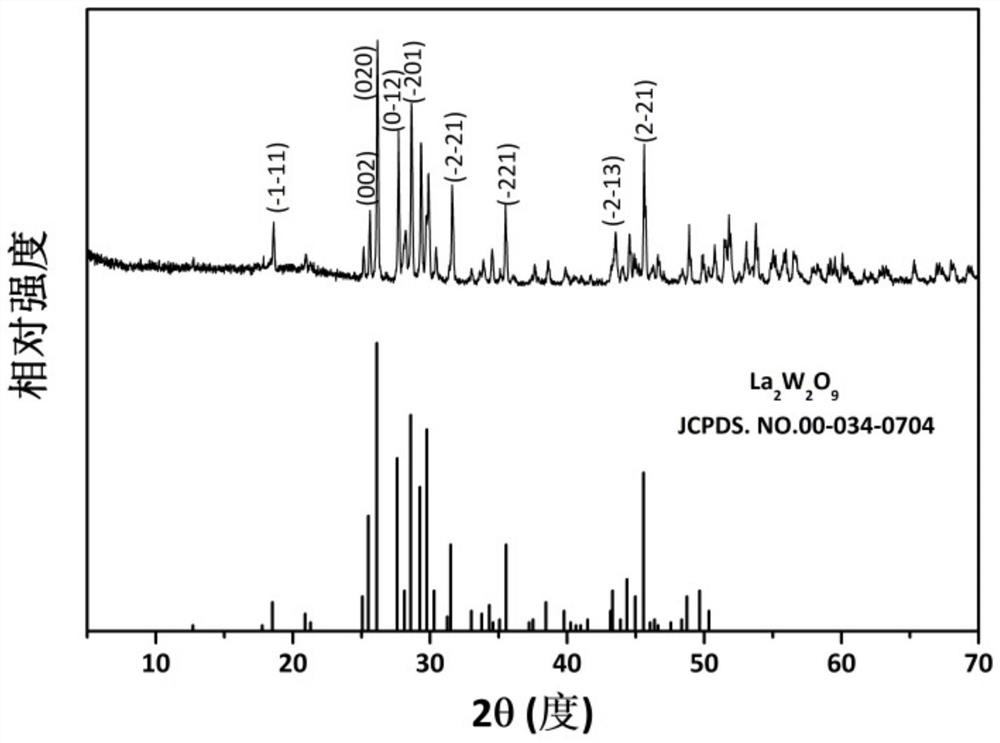

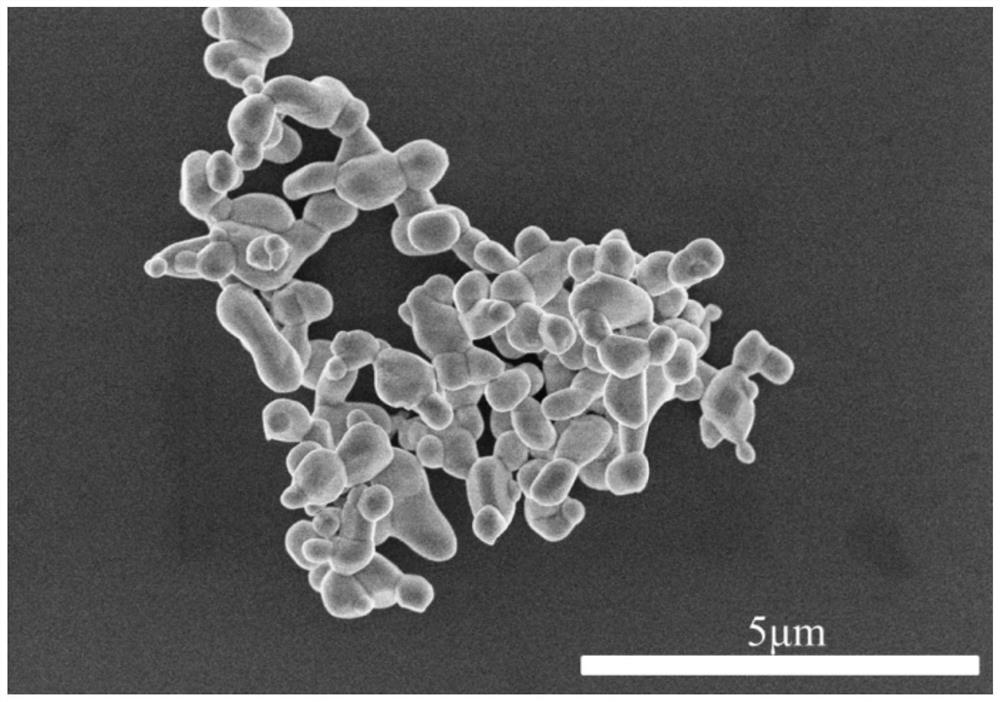

ActiveCN112812774ASmall sizeUniform sizeThermometers using physical/chemical changesEnergy efficient lightingDispersityActive agent

The invention belongs to the field of material science and technology, and discloses fluorescent powder for non-contact fluorescence temperature measurement and a preparation method thereof. The component of the fluorescent powder for non-contact temperature measurement is (RE<1-x-y>Yb<x>Er<y>)<2>W<2>O<9>, and the fluorescent powder for non-contact temperature measurement has high absolute sensitivity (Sa=0.0253 K<-1>) and relative sensitivity (Sr=0.0105 K<-1>) by using the fluorescence intensity ratio of thermal coupling energy levels 2H11 / 2 to 4I15 / 2 and 4S3 / 2 to 4I15 / 2 of rare earth ions Er<3+> for temperature measurement. The preparation method is low in temperature, energy-saving, simple in synthesis process and easy to operate. The reaction is carried out at room temperature to 70 DEG C to obtain a precursor product, and the (RE<1-x-y>Yb<x>Er<y>)<2>W<2>O<9> fluorescent powder can be obtained through simple calcination. No organic matter or surfactant is added in the synthesis process, and nano powder with uniform size and good dispersity can be obtained through simple precipitation and subsequent calcination.

Owner:BOHAI UNIV

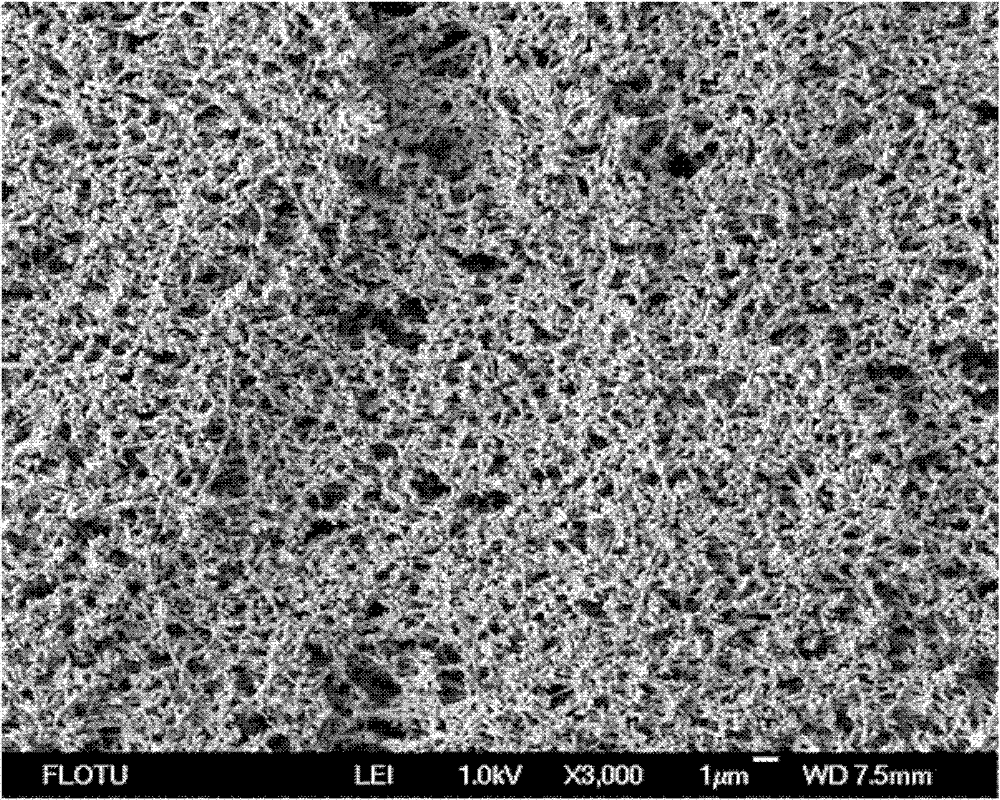

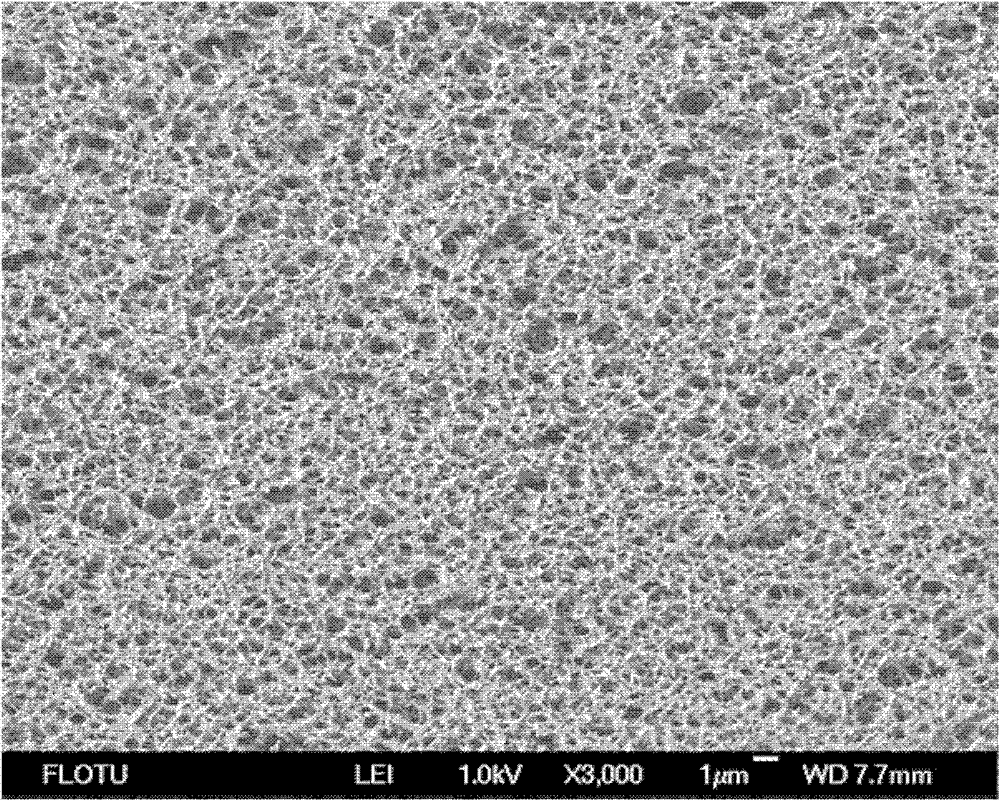

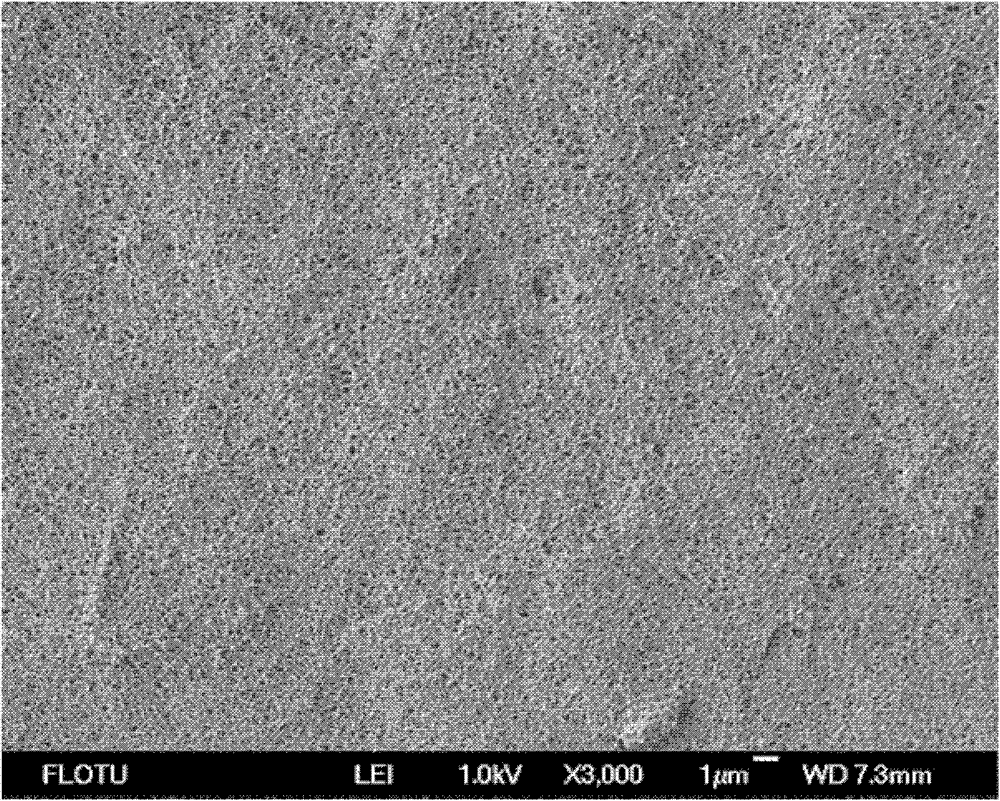

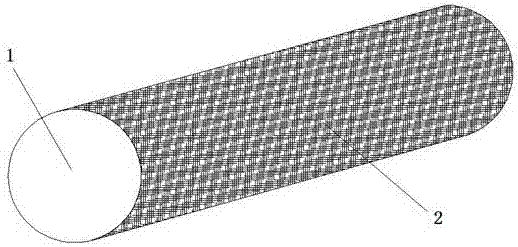

Method for preparing ethylene-trifluorochlor oethylene copolymer porous membrane

ActiveCN102228805BBroaden your optionsBroaden the range of concentration optionsSemi-permeable membranesPolymer sciencePorous membrane

The invention discloses a method for preparing an ethylene-trifluorochlor oethylene copolymer porous membrane, and belongs to the fields of high polymer material science and technology. In the method, a proper solvent, namely diethyl phthalate is provided, and the ethylene-trifluorochlor oethylene copolymer porous membrane is prepared by initiating phase separation by reducing the temperature of an ethylene-trifluorochlor oethylene copolymer / diethyl phthalate system. When the polymer concentration is lower than 60 weight percent, the section of the ethylene-trifluorochlor oethylene copolymer porous membrane has a uniform spongeous structure. By controlling the conditions such as the concentration of the ethylene-trifluorochlor oethylene copolymer, cooling rate and the like, the microstructure of the membrane can be controlled.

Owner:TSINGHUA UNIV

Technological composite decorative material

The invention provides a technological composite decorative material, comprising a core board, the raw materials of the core board and the parts by weight of each raw material are 22-34 parts of balsa wood powder; 16-29 parts of bamboo charcoal powder; 11-19 parts of cut glass fiber; 4-9 parts of polyolefin elastomer; 9-16 parts of composite vegetable dye; 16-23 parts of soybean protein fiber; 17-21 parts of cyanuric chloride; polyhexamethylene guanidine propionate 7‑15 parts; 11‑26 parts of chitosan quaternary ammonium salt; 13‑25 parts of triethanolamine; 3‑9 parts of gallic acid. The invention has the characteristics of high hardness and light specific gravity, and its properties of compression resistance, bending resistance and impact resistance are superior to those of natural wood. Environmental protection, flame retardant, moisture-proof, moth-proof, no deformation, high hardness, not afraid of water immersion, easy maintenance, high wear resistance, longer service life, etc. Simultaneously, the present invention also adds compound vegetable dyes, endows multiple colors, and simultaneously the color and luster is brighter, and the three-dimensional sense of texture is stronger.

Owner:龙门县品汐竹木制品有限公司

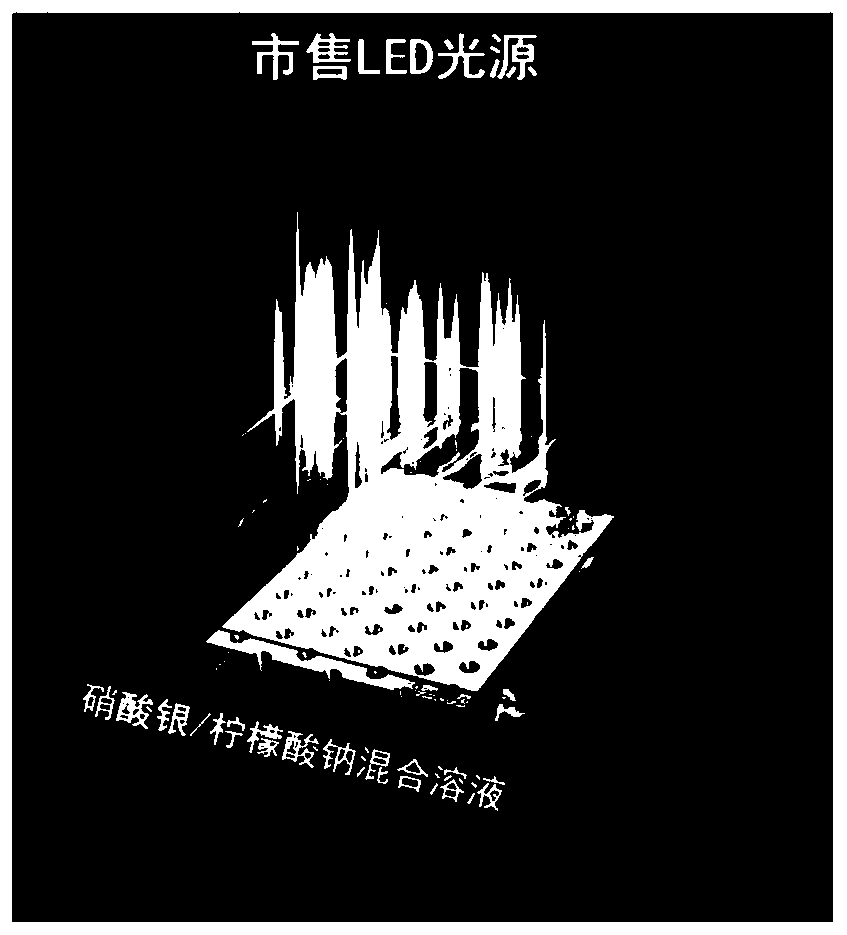

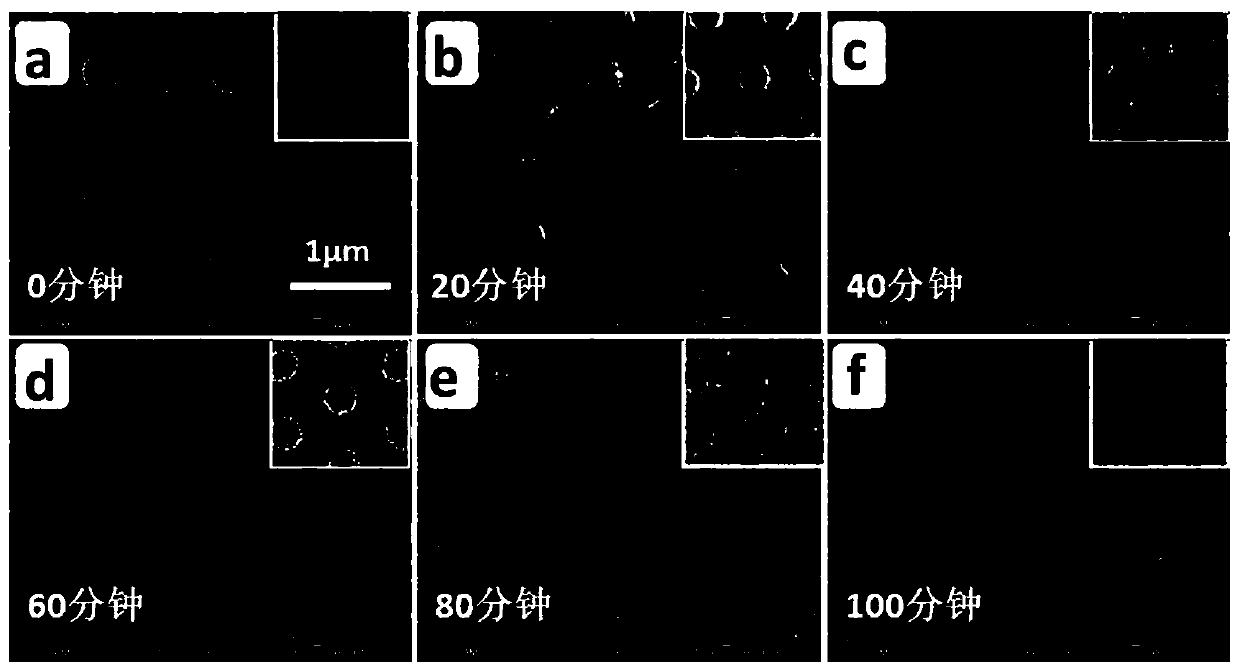

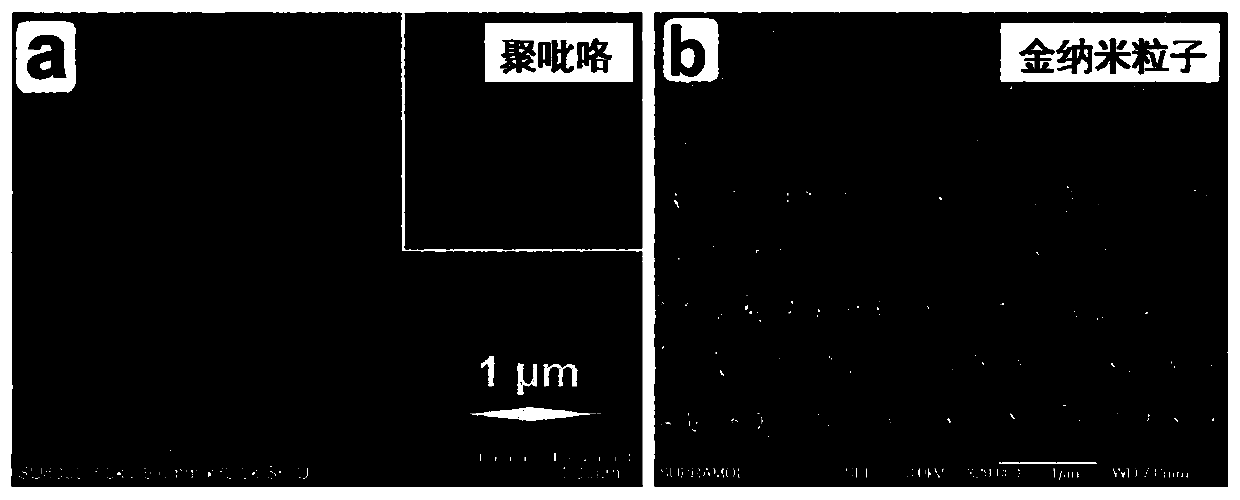

Surface plasma resonance induced multilevel structure and modification method thereof

InactiveCN110923681AReduce sizeEasy to prepareVacuum evaporation coatingSputtering coatingMicro nanoNano structuring

The invention relates to a surface plasma resonance induced multilevel structure and a modification method thereof, and belongs to the field of material science and technology. The surface plasma resonance induced multilevel structure and the modification method thereof uses a colloidal microsphere gas-liquid interface self-assembly method, a mask etching method and a physical vapor deposition method successively to prepare a metal hollow cone film structure, then uses a micro-nano structure liquid phase transfer and inversion method to invert the metal hollow cone array film on a target substrate, and then a metal inverted hollow nano cone array film structure is obtained. According to the surface plasma resonance induced multilevel structure and the modification method thereof, the sizeand distribution of a silver nanoparticle can be well controlled by adjusting the irradiation time of commercial LED light source; in addition, the method can also be used for modifying gold nanoparticles and polypyrrole particles; and in the surface plasma resonance induced multilevel structure and the modification method thereof, the metal inverted hollow nano cone array film is only used as a specific structure for experimental implementation, and in fact, the method is suitable for surface modification of various micro nano structures with surface plasmon resonance and can be used for large-area modification of multilevel structures.

Owner:JILIN UNIV

Process of growing magnesium oxide crystal by magnesite

InactiveCN1560331AEasy to growEasy to masterPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

The invention relates to a crystal growth science and technique, especially a method of growing magnesia crystal by magnesite. It is using magnesite as raw material, using a cold pot as a furnace body, firstly baking the magnesite, respectively making three kinds of light-burned magnesia and mixing the three in proportion, placing the mixture in the furnace body, adopting three-phase AC electric melting process to heat, control the curves of increasing temperature, constant temperature and lowering temperature, and obtaining a sparkling and crystal-clear graceful cubic magnesia crystal.

Owner:LIAONING ZHONGDA SUPERCONDUCTING MATERIAL

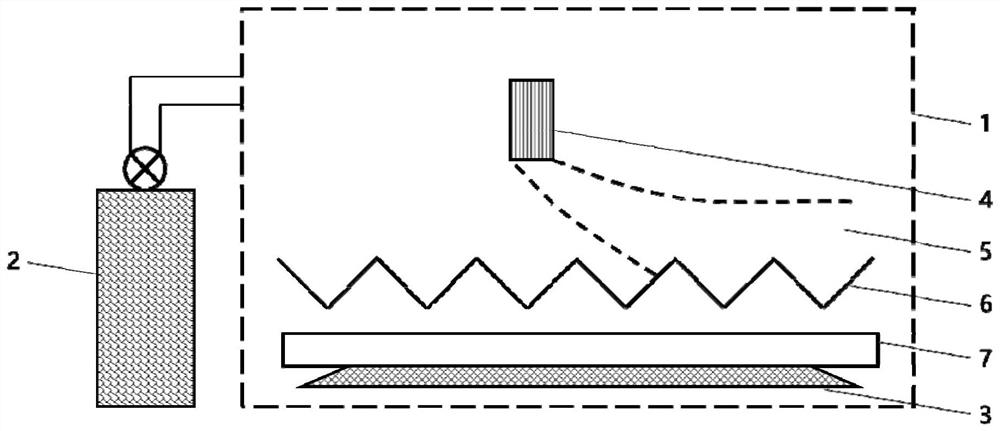

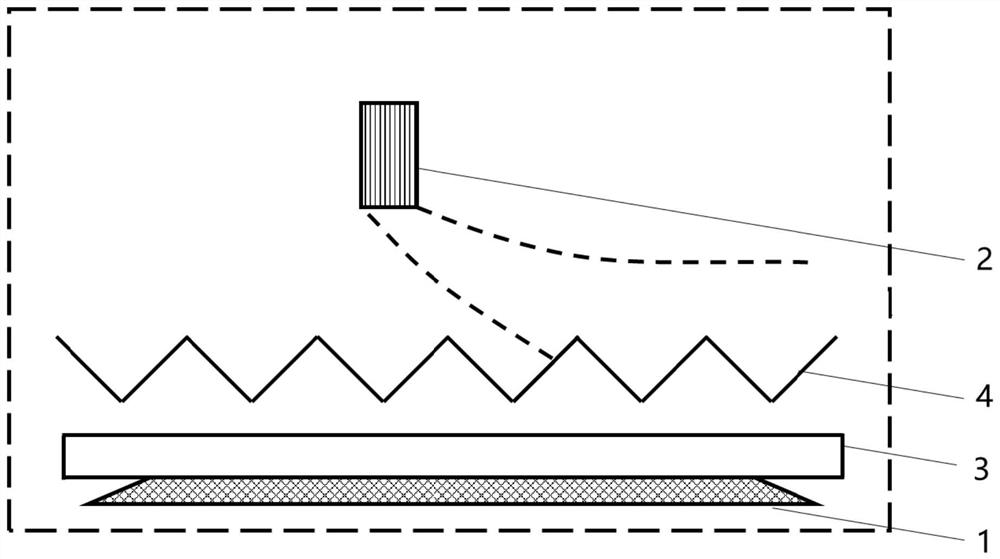

Low-pressure chamber high-frequency micro-vibration wetting coating method and equipment

PendingCN112490370AHigh speedImprove coating qualitySolid-state devicesSemiconductor/solid-state device manufacturingThin membraneSolar cell

The invention discloses a low-pressure chamber high-frequency micro-vibration wetting coating method and equipment, and belongs to the technical field of material science and technology and thin filmpreparation. The method comprises the following steps: (1) placing a solar cell substrate in a closed chamber with the pressure of 1,000 Pa-5,0000 Pa; 2) coating the surface of a solar cell substratewith the coating substance, and performing normal vibration on the solar cell substrate by using a vibration source with the frequency of 20-200KHz and the amplitude of 10nm-100nm to form a liquid film on the surface of the solar cell substrate; and 3) drying and annealing the liquid film on the surface of the solar cell substrate to form a wet coating film on the surface of the solar cell substrate. According to the method, under the action of high-frequency micro-vibration, the perovskite solution or sol has a dynamic wetting effect on an undulating interface of the pit of the solar cell substrate, bubbles at the pit are effectively discharged and infiltrated into the pit, uncovered holes between the perovskite film and the solar cell substrate are greatly reduced, and the coating speedand the coating quality of the perovskite solution can be greatly improved.

Owner:XI AN JIAOTONG UNIV

Science and technology decoration material

The invention provides a technological decorative material, comprising a core board, the raw materials of the core board and the parts by weight of each raw material are 22-34 parts of balsa wood powder; 16-29 parts of bamboo charcoal powder; 11-19 parts of glass fiber; 4-9 parts of polyolefin elastomer; 9-16 parts of composite vegetable dye; 16-23 parts of basalt fiber; 17-21 parts of cyanuric chloride; 7-15 parts of cinchonidine sulfate; 11-26 parts of chitosan quaternary ammonium salt; 13-25 parts of octadecyl dimethylamine; 3-9 parts of ethylene carbonate. The invention has the characteristics of high hardness and light specific gravity, and its properties of compression resistance, bending resistance and impact resistance are superior to those of natural wood. Environmental protection, flame retardant, moisture-proof, moth-proof, no deformation, high hardness, not afraid of water immersion, easy maintenance, high wear resistance, longer service life, etc. Simultaneously, the present invention also adds compound vegetable dyes, endows multiple colors, and simultaneously the color and luster is brighter, and the three-dimensional sense of texture is stronger.

Owner:龙门县品汐竹木制品有限公司

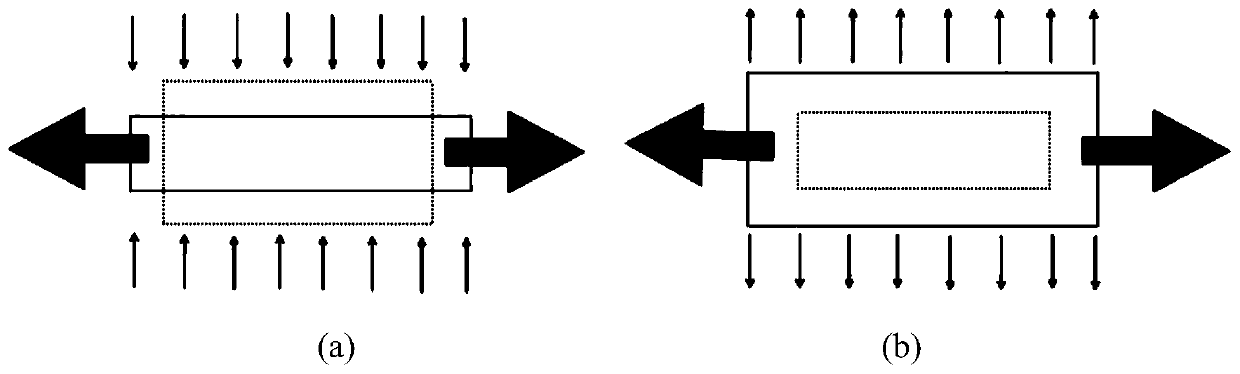

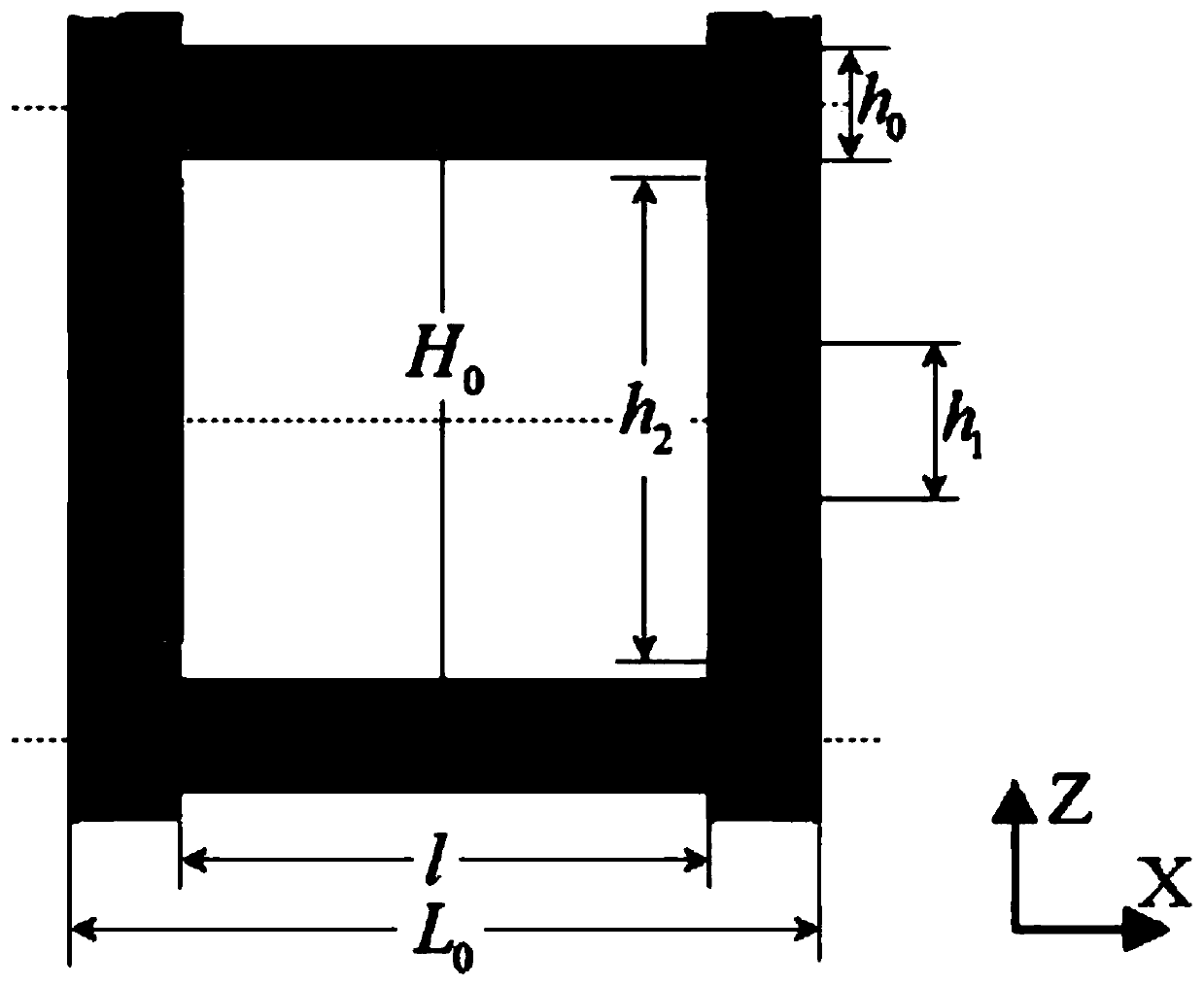

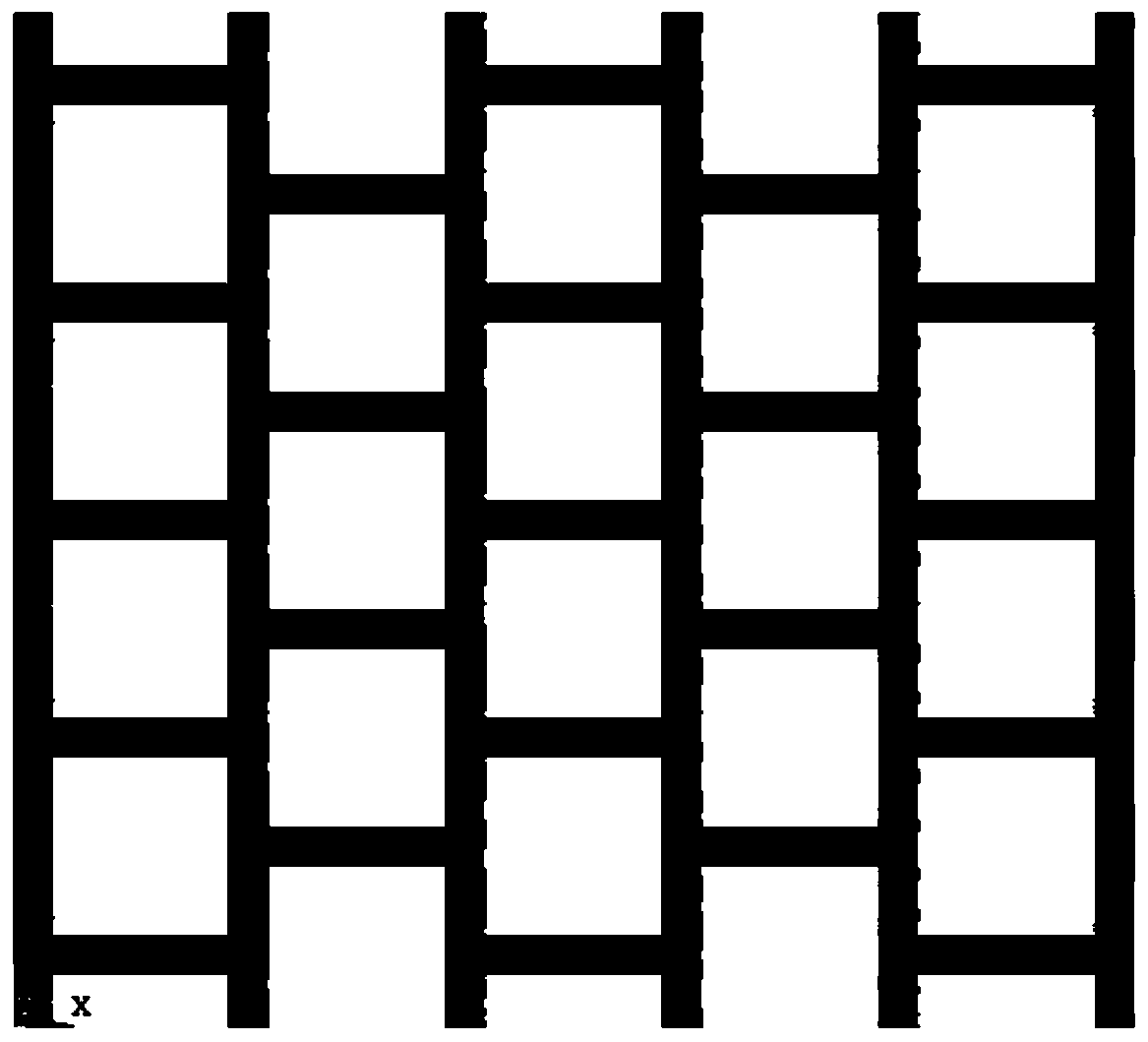

A dual-material large-stiffness porous negative Poisson's ratio cell and its structural components

ActiveCN108389258BImprove stiffness performanceDesign optimisation/simulationSpecial data processing applicationsEngineeringMechanical engineering

A dual-material large-stiffness porous negative Poisson's ratio cell and its structural components belong to the field of elastic material science and technology. This dual-material large-stiffness porous negative Poisson's ratio cell is a loop-shaped structure, including two mirror-symmetrically arranged sides and two parallel and symmetrical beams. The sides are composed of dual materials and are dual-material sides. edge, showing a negative Poisson's ratio effect. The dual-material large-stiffness porous negative Poisson's ratio structural component is a three-dimensional structure, consisting of multiple dual-material large-stiffness porous negative Poisson's ratio cells arranged in three dimensions. Finite element numerical simulations were conducted on this structural component, and the results verified that it has a negative Poisson's ratio effect and has higher stiffness performance than traditional honeycomb structures. This structural design with large stiffness expands the application range of negative Poisson's ratio structures. , and can achieve functions such as shock absorption and energy absorption based on changes in the adaptive stiffness performance of the structure.

Owner:NORTHEASTERN UNIV LIAONING

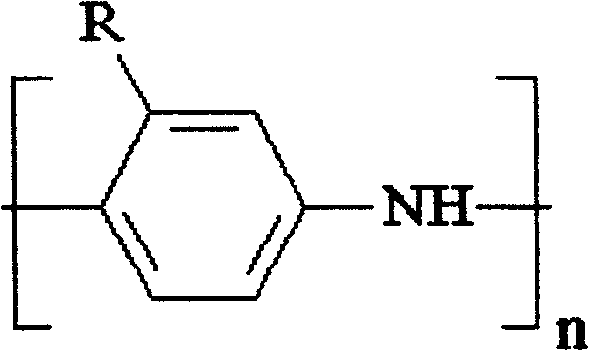

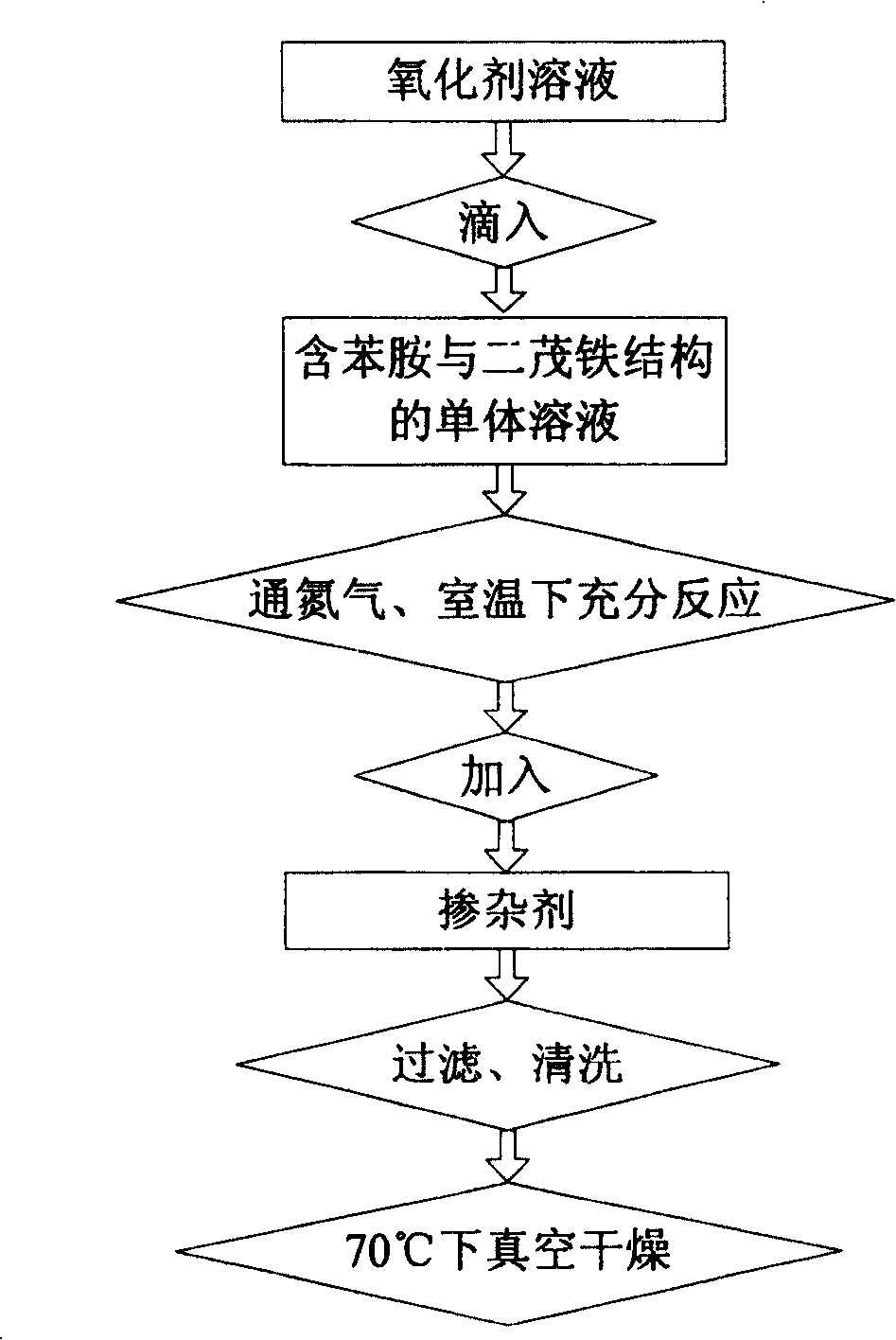

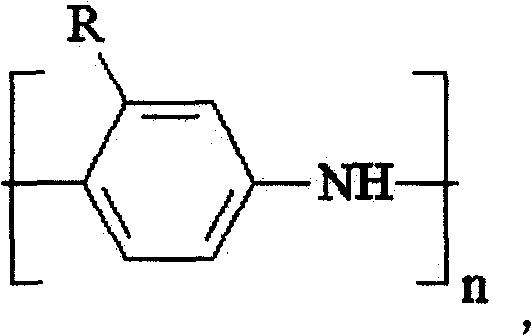

Organic polymeter as electromagnetic shielding material and its prepn process

InactiveCN100427546COvercome the shortcoming of low overall shielding effectivenessLow densityMagnetic/electric field screeningPolymer scienceAniline

The organic polymer as electromagnetic shielding material and its preparation process belongs to the field of material science and technology. The organic polymer as electromagnetic shielding material has organic polymer of polymerization degree n of 20-400 in the shown structure as the main component. It is prepared with the monomer with aniline and ferrocene as main material, and through slowly dropping oxidant solution into the monomer solution to polymerize and adding proper amount of dopant. The polymer has in its molecular structure polyaniline as the conducting mother substance and ferrocene as the magnetic radical, so that it has both electric conductivity and magnetism. It has high comprehensive shielding effect, low density, wide applicable frequency range, low temperature coefficient, low magnetic loss and other excellent characteristics, and may find wide application in electromagnetic shielding, wave absorption, etc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

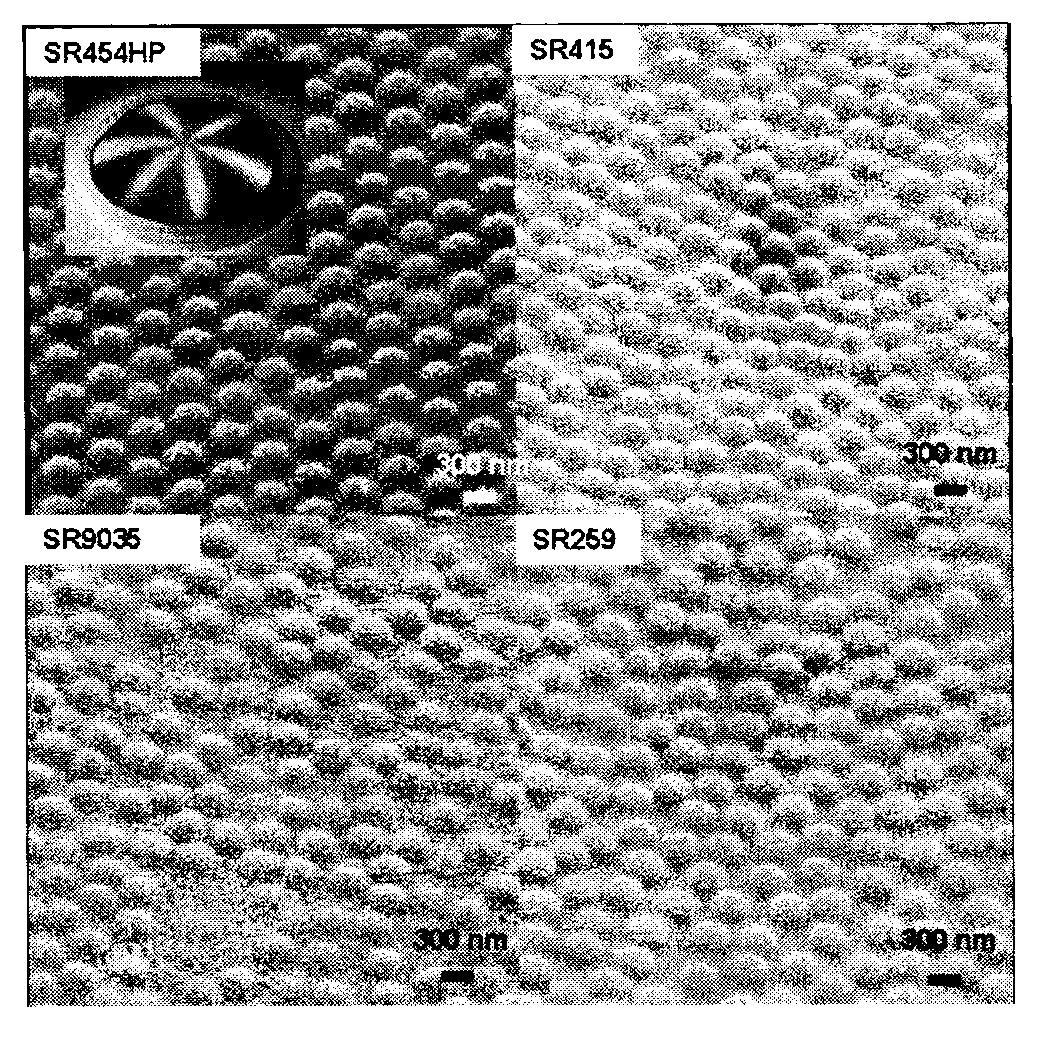

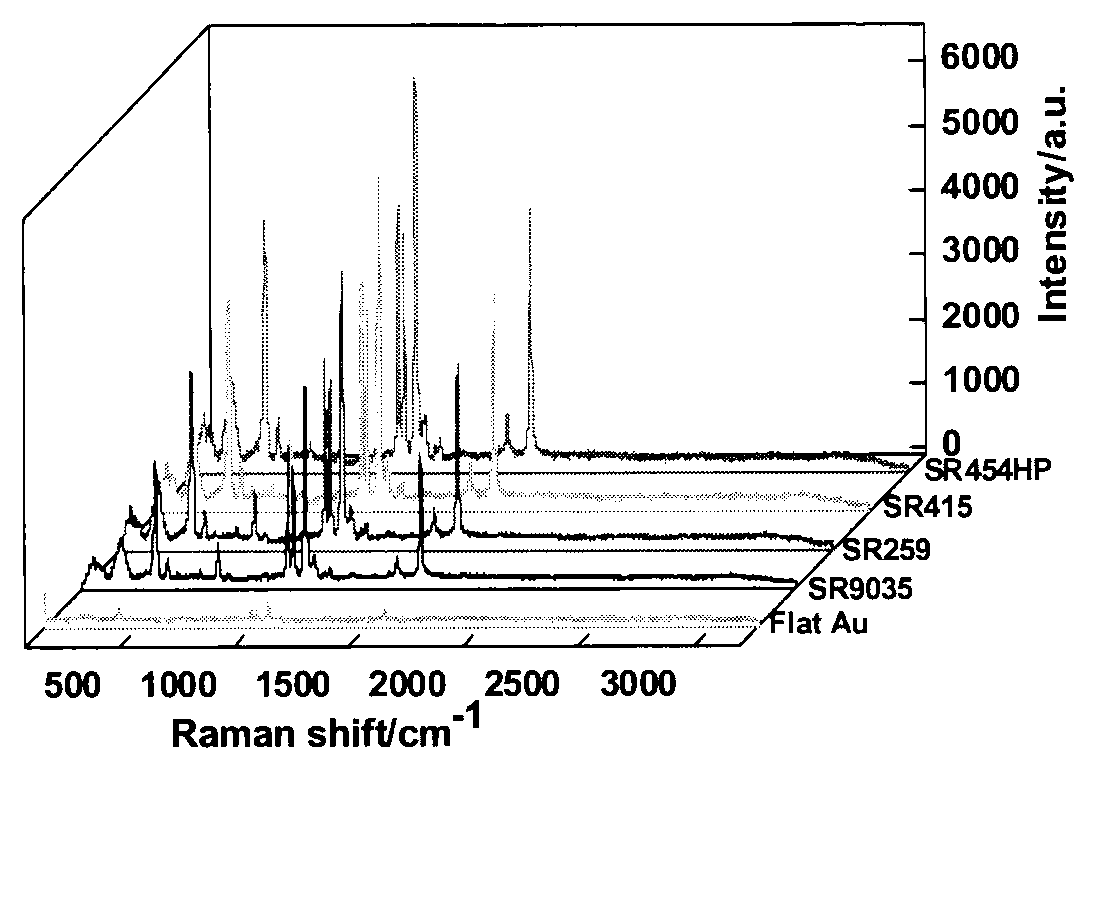

Method for regulating structure of nanosphere convex plane array type SERS (Surface Enhanced Raman Scattering) substrate

The invention discloses a method for regulating the structure of a nanosphere convex plane array type SERS (Surface Enhanced Raman Scattering) substrate, belonging to the field of nanometer material science and technology. According to the method, the regulation on the structure of a nanosphere convex plane array type SERS substrate can be realized by changing the varieties of polymerizable monomers, and the enhanced Raman scattering property of the surface of the nanosphere convex plane array type SERS substrate to laser can be further regulated. The method for regulating structure of the nanosphere convex plane array type SERS substrate has the advantages of being simple in steps, having no environment pollution, being capable of realizing high-flux production and the like.

Owner:JIANGNAN UNIV

Method and equipment for enhancing wettability of thin film by utilizing high-frequency micro-vibration

PendingCN112490373AHigh speedImprove coating qualitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrical battery

The invention discloses a method and equipment for enhancing wettability of a thin film by utilizing high-frequency micro-vibration, and belongs to the technical field of material science and technology and thin film preparation. The method comprises the following steps: firstly, coating the surface of a solar cell substrate or a thin film with a coating substance system, enabling the solar cell substrate to vibrate by adopting a plurality of vibration sources to form a layer of liquid film on the surface of the solar cell substrate or the thin film, and secondly, drying and annealing the liquid film on the surface of the solar cell substrate or the thin film, and forming a wetting film on the surface of the solar cell substrate or film. Under the action of multi-source multi-direction high-frequency micro-vibration, a high-frequency dynamic wetting effect is continuously generated at the interactive front edge of the liquid film and the solar cell substrate or the thin film pit, so that bubbles in the pit are expelled, infiltration and filling of large-roughness, large-fluctuation and deep pits are realized, uncovered areas of the thin film and the solar cell substrate or the thinfilm are greatly reduced, the coating speed and the coating quality of the thin film are effectively improved, and a technical scheme is provided for cheap and rapid preparation of large-area perovskite solar cells.

Owner:XI AN JIAOTONG UNIV

Process of growing magnesium oxide crystal by magnesite

InactiveCN1265032CEasy to growEasy to masterPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

The invention relates to a crystal growth science and technique, especially a method of growing magnesia crystal by magnesite. It is using magnesite as raw material, using a cold pot as a furnace body, firstly baking the magnesite, respectively making three kinds of light-burned magnesia and mixing the three in proportion, placing the mixture in the furnace body, adopting three-phase AC electric melting process to heat, control the curves of increasing temperature, constant temperature and lowering temperature, and obtaining a sparkling and crystal-clear graceful cubic magnesia crystal.

Owner:LIAONING ZHONGDA SUPERCONDUCTING MATERIAL

A kind of preparation method of porous carbon supported tungsten carbide composite material

ActiveCN111545231BWell mixedAvoid reunionMaterial nanotechnologyCatalyst activation/preparationPtru catalystPorous carbon

The invention discloses a method for preparing a porous carbon-loaded tungsten carbide composite material, which belongs to the field of material science and technology. The material is highly dispersed and uniformly loaded tungsten carbide nanoparticles on a carbon skeleton with a large network of pore structures. The specific preparation method is: using metal nitrate, tungsten source, fuel and soluble organic carbon source as raw materials, the precursor of tungsten oxide and other metal oxides uniformly embedded in the carbon matrix is obtained through the solution combustion synthesis reaction, and the synergistic coupling pore-forming effect is used. , after subsequent high-temperature carbonization and pickling to remove oxides, the specific surface area is as high as 1000m 2 / g or more porous carbon-supported tungsten carbide materials. The raw materials of the present invention are easy to obtain, the process is simple, and the requirements for equipment are low. The prepared porous carbon-supported tungsten carbide powder material has fine particles, narrow particle size distribution, good dispersibility, high specific surface area and pore volume, and uniform loading of tungsten carbide particles. It is not easy to fall off, and as a platinum-substituting catalyst, it can significantly reduce the cost of electrocatalysts, and at the same time improve its hydrogen evolution catalytic performance, and has good industrial application prospects.

Owner:UNIV OF SCI & TECH BEIJING

A high-purity large-size silicon carbide single crystal and its preparation process

InactiveCN103757703BHigh densitySmall sizePolycrystalline material growthFrom frozen solutionsElectric arc furnaceCrystal structure

The invention discloses a high-purity large-size silicon carbide single crystal and a preparation process thereof, and belongs to the field of the material science and technology. The preparation process comprises the steps of taking high-purity SiC powder as the raw material, realizing rational grain composition of the SiC powder different in grain size and obtaining the maximum loading density, next, loading the SiC powder in an ultrahigh-power vertical electric arc furnace, carrying out static smelting at a high temperature and under high pressure, and then growing the high-purity large-size silicon carbide single crystal through recrystallization. The manufacturing method of the high-purity large-size silicon carbide single crystal has the advantages of simple process and low cost, and the prepared silicon carbide single crystal is high in purity (> 99.99%), large in size (greater than or equal to 25mm), colourless to light green and transparent, and has a 3C crystal structure. The preparation process is simple, low in cost, high in efficiency, and advantageous for popularization and application.

Owner:汪长安

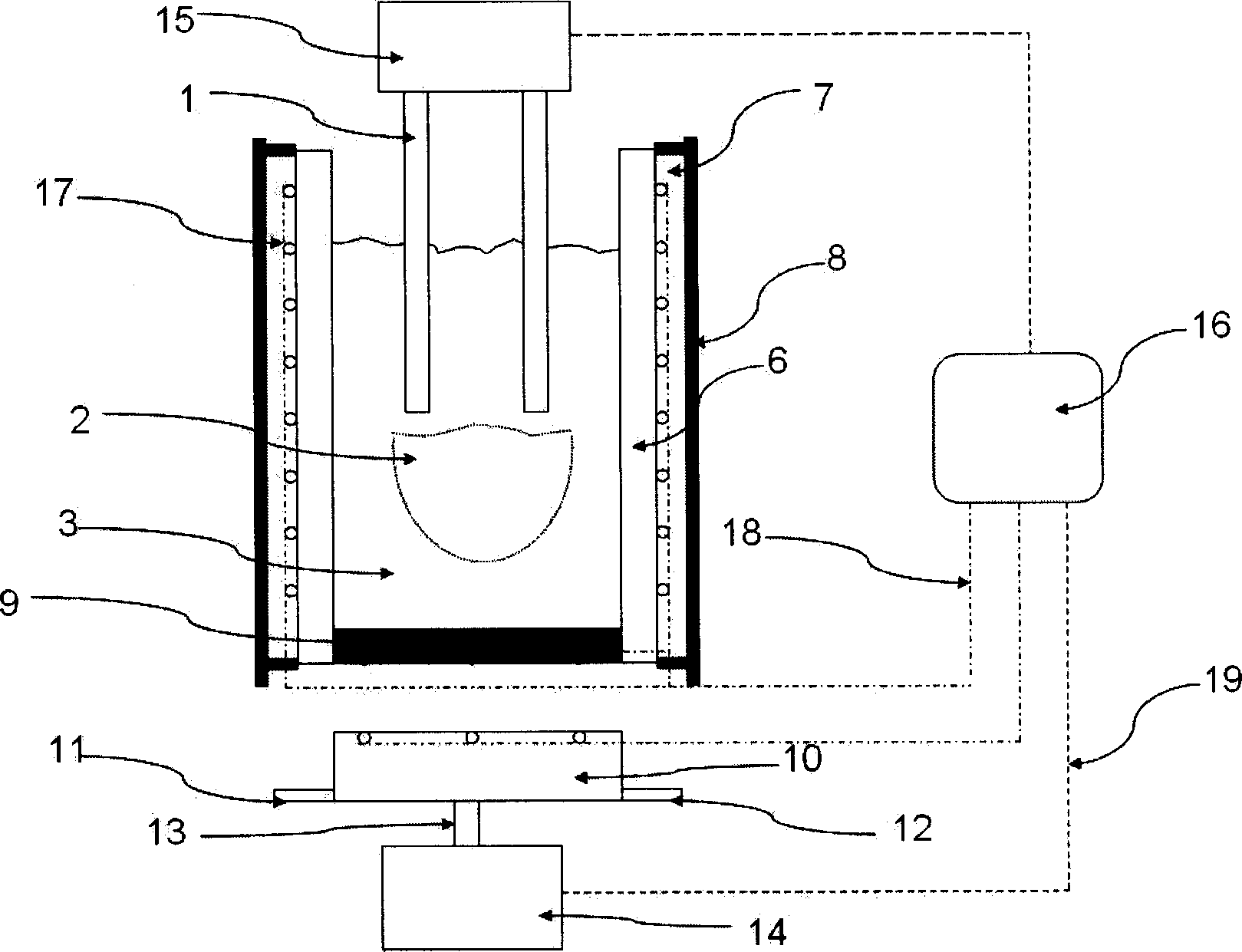

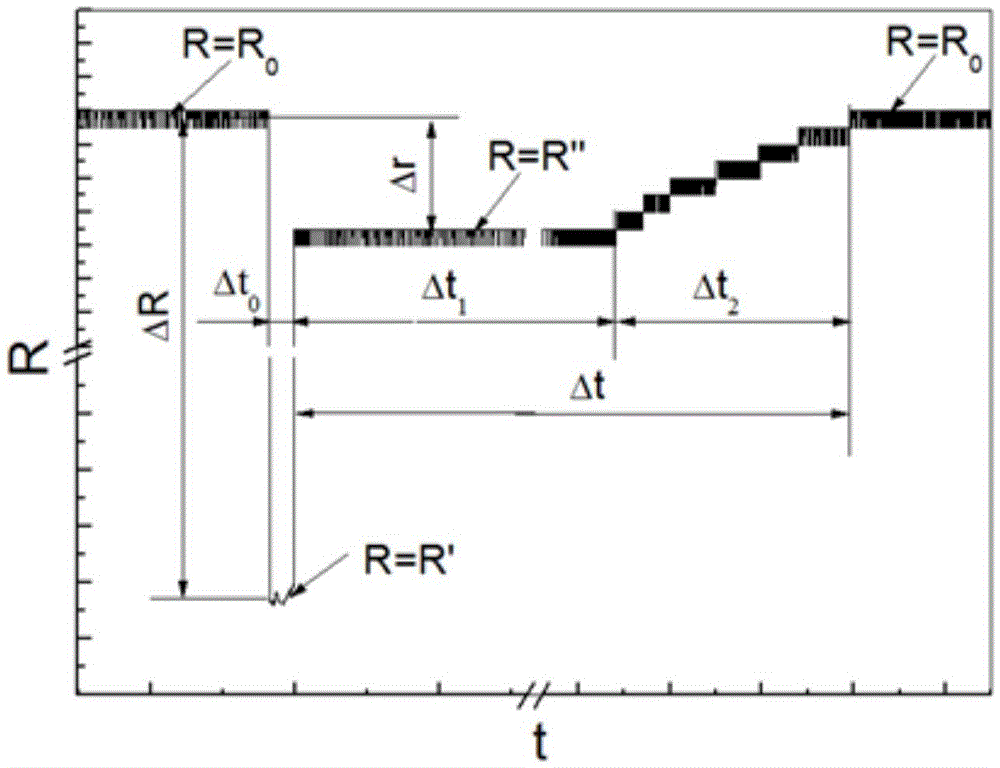

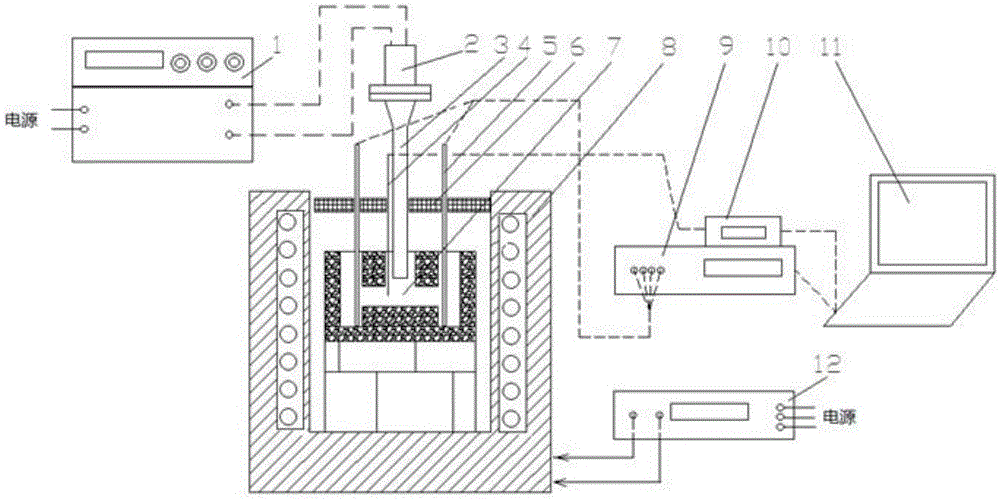

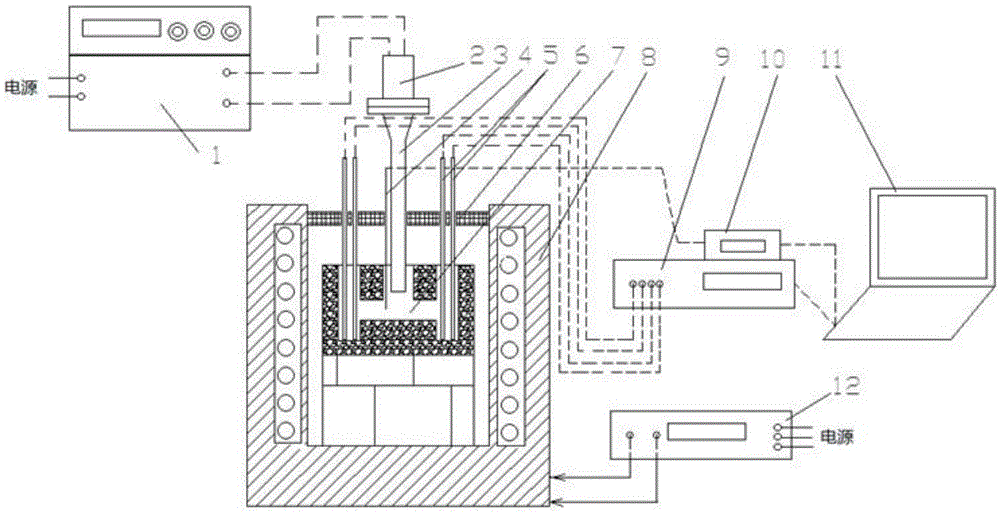

An on-line detection device for the structure change of metal melt caused by ultrasonic pretreatment

ActiveCN104076065BAccurate detectionReal-time detectionMaterial resistanceCollection systemData acquisition

The invention belongs to the field of materials science and technology, and specifically relates to an online detection device for structural changes in metal melt caused by ultrasonic pretreatment. The detection device of the present invention consists of a heating insulation system, a metal melt storage unit, a power ultrasonic system, a melt resistance or resistivity detection system, a melt temperature signal acquisition system, a data acquisition and processing system, and the like. The device of the present invention can detect and utilize the structurally sensitive physical parameter - the change amount Δr of the resistance parameter to characterize the structural change of the metal melt caused by ultrasound. It successfully solves the insulation problem of the power ultrasonic introduction rod and overcomes the problem of using voltammetry. The influence of the ultrasonic rod when measuring the resistance of ultrasonic-induced metal melt, and using advanced electronic measurement technology and computer technology to achieve real-time, synchronous, continuous and high-precision automatic collection and processing of resistance and temperature data, and using the two-electrode method and four-electrode method All methods can achieve accurate measurement.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com