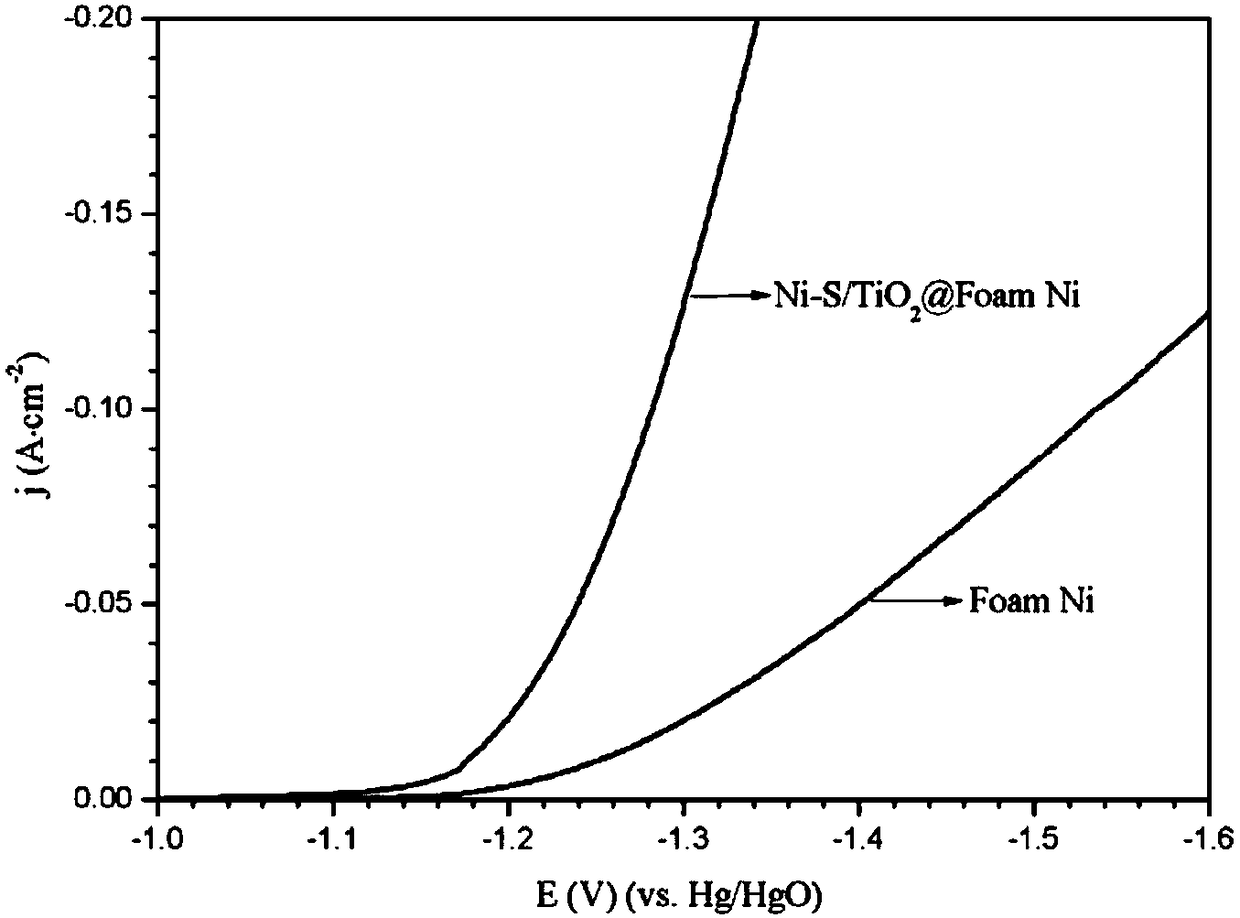

Porous Ni-S/TiO2 composite hydrogen evolution electrode and preparation method thereof

A hydrogen evolution electrode and composite electrodeposition technology, which is applied in the field of electrocatalytic hydrogen production and material science, can solve the problems of high cost, poor stability, and low catalytic activity of hydrogen evolution electrodes, and achieve improved mechanical stability, good stability, and hydrogen evolution catalysis good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the composite electrodeposition method is mainly used to deposit the nickel-sulfur coating on the surface of the three-dimensional nickel foam. At the same time, in the electroplating process, the nano-sized TiO in the composite plating solution is mixed by magnetic stirring 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0026] (1) Selection and pretreatment of nickel foam

[0027] The purity of the three-dimensional porous nickel foam is 99.9wt%, and the surface density is 480g / m 2 . At room temperature, degrease and degrease the nickel foam in acetone for 10 minutes, and clean it with ultrapure water; then, put it into 3M (molar concentration) hydrochloric acid for acidification and activation treatment for 5 minutes; finally, put it into ultrapure water for ultrasonic cleaning for 5 minutes and bake Dry and set aside.

[0028] (2) Preparation of Ni-S / TiO 2 Compound electrode

[0029] The nickel foam pretreated i...

Embodiment 2

[0035] In this embodiment, the composite electrodeposition method is mainly used to deposit the nickel-sulfur coating on the surface of the three-dimensional nickel foam. At the same time, in the electroplating process, the nano-sized TiO in the composite plating solution is mixed by magnetic stirring 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0036] (1) Selection and pretreatment of nickel foam

[0037] The purity of the three-dimensional porous nickel foam is 99.9%, and the surface density is 550g / m 2 . At room temperature, the nickel foam was degreased and degreased in acetone for 5 minutes, and cleaned with ultrapure water; then, it was acidified and activated in 3M hydrochloric acid for 5 minutes; finally, it was ultrasonically cleaned in ultrapure water for 5 minutes and dried for use.

[0038] (2) Preparation of Ni-S / TiO 2 Compound electrode

[0039] The nickel foam pretreated in the step (1) is put into the composite plating solut...

Embodiment 3

[0043] In this embodiment, the composite electrodeposition method is mainly used to deposit the nickel-sulfur coating on the surface of the three-dimensional nickel foam. At the same time, in the electroplating process, the nano-sized TiO in the composite plating solution is mixed by magnetic stirring 2 Doped into the nickel-sulfur coating, the specific steps are as follows:

[0044] (1) Selection and pretreatment of nickel foam

[0045] The purity of the three-dimensional porous nickel foam is 99.9%, and the surface density is 500g / m 2 . At room temperature, the nickel foam was degreased and degreased in acetone for 15 minutes, and cleaned with ultrapure water; then, it was acidified and activated in 3M hydrochloric acid for 5 minutes; finally, it was ultrasonically cleaned in ultrapure water for 5 minutes and dried for use.

[0046] (2) Preparation of Ni-S / TiO 2 Compound electrode

[0047] The nickel foam pretreated in step (1) is put into the composite plating solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com