Technological composite decorative material

A decorative material and technological technology, applied in the field of scientific and technological composite decorative materials, can solve the problems of less research and application of glass fiber, and achieve the effects of more dynamic and dynamic patterns, brighter colors and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

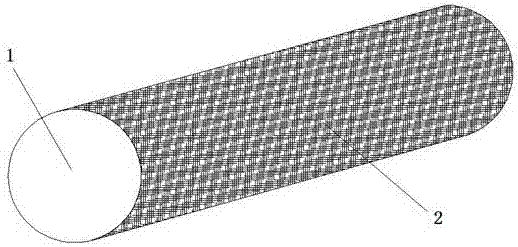

[0070] A technological composite decorative material, comprising a core board 1, the raw materials of the core board 1 and the parts by weight of each raw material are

[0071] 27 parts of balsa wood powder;

[0072] 20 parts of bamboo charcoal powder;

[0073] 15 parts of low floating fiber non-alkali long cut glass fiber;

[0074] 6 parts of polyolefin elastomer;

[0075] 12 parts of compound vegetable dyes;

[0076] 20 parts of soybean protein fiber;

[0077] 19 parts of cyanuric chloride;

[0078] 10 parts of polyhexamethyleneguanidine propionate;

[0079] Chitosan quaternary ammonium salt 19 parts;

[0080] 18 parts of triethanolamine;

[0081] 6 parts of gallic acid;

[0082] Described balsa wood powder is the powder that the leftovers when balsa wood manufactures products are ground into, and particle size is 130 microns;

[0083] Described bamboo charcoal powder is the powder that bamboo obtains after calcining, grinding, pickling, calcining, and particle size...

Embodiment 2

[0093] A technological composite decorative material, comprising a core board 1, the raw materials of the core board 1 and the parts by weight of each raw material are

[0094] 22 parts of balsa wood powder;

[0095] 29 parts of bamboo charcoal powder;

[0096] 11 parts of low floating fiber non-alkali long cut glass fiber;

[0097] 9 parts of polyolefin elastomer;

[0098] 9 parts of compound vegetable dyes;

[0099] 16 parts of soybean protein fiber;

[0100] 21 parts of cyanuric chloride;

[0101] 7 parts of polyhexamethyleneguanidine propionate;

[0102] Chitosan quaternary ammonium salt 11 parts;

[0103] 13 parts of triethanolamine;

[0104] 3 parts of gallic acid;

[0105] Described balsa wood powder is the powder that the leftovers when balsa wood manufactures products are ground into, and particle size is 150 microns;

[0106] Described bamboo charcoal powder is the powder that bamboo obtains after calcining, grinding, pickling, calcining, and particle size i...

Embodiment 3

[0116] A technological composite decorative material, comprising a core board 1, the raw materials of the core board 1 and the parts by weight of each raw material are

[0117] 34 parts of balsa wood powder;

[0118] 16 parts of bamboo charcoal powder;

[0119] 19 parts of low floating fiber non-alkali long cut glass fiber;

[0120] 4 parts polyolefin elastomer;

[0121] 16 parts of compound vegetable dyes;

[0122] 16 parts of soybean protein fiber;

[0123] 21 parts of cyanuric chloride;

[0124] 7 parts of polyhexamethyleneguanidine propionate;

[0125] Chitosan quaternary ammonium salt 26 parts;

[0126] 25 parts of triethanolamine;

[0127] 9 parts of gallic acid;

[0128] Described balsa wood powder is the powder that the leftovers when balsa wood manufactures products are ground into, and particle size is 100 microns;

[0129] Described bamboo charcoal powder is the powder that bamboo obtains after calcining, grinding, pickling, calcining, and particle size is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com