Preparation method of polylactic acid fiber pre-spinning colorant

A technology of polylactic acid fiber and pre-spinning coloring, applied in the fields of fine chemical industry and material science, to achieve the effect of high surface energy and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

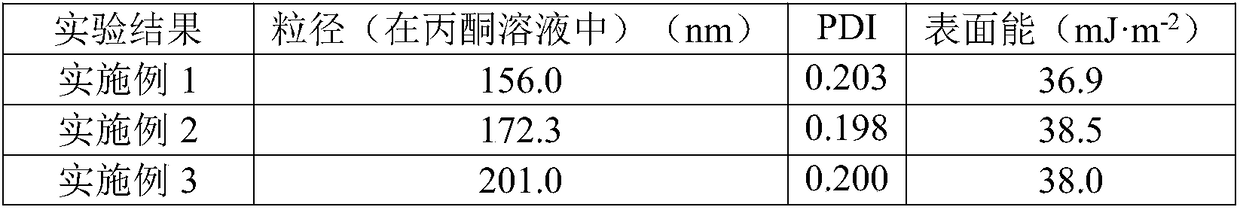

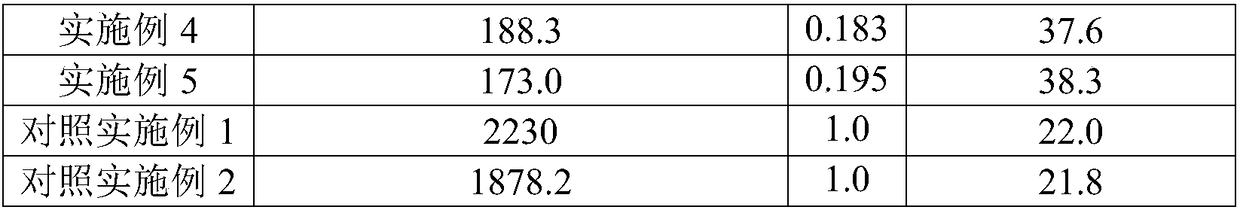

Examples

Embodiment 1

[0024] Put 1g of carbon black, 1g of silane coupling agent KH560, 60g of absolute ethanol, 6g of deionized water and 0.2g of ammonia into a beaker for ultrasonic treatment for 15min, then transfer to a three-necked flask, stir at 40°C for 12h, and then use Centrifugal cleaning with absolute ethanol for several times, drying, and grinding for later use; place a three-necked flask with constant speed stirring in an oil bath at a certain temperature, vacuumize and flush with nitrogen, and pour the above-mentioned modified pigment into 100g of tetrahydrofuran solution placed in an ultrasonic machine for ultrasonic treatment for 30 minutes, and then transferred to the flask together with 1 g of lactide. When the lactide began to dissolve, 0.03 g of stannous octoate was added dropwise, condensed and refluxed for a certain period of time. After the reaction, it was centrifuged and washed several times, and excess polylactic acid was washed away with chloroform, and finally put into a ...

Embodiment 2

[0026] Put 2g of aluminum powder, 1g of silane coupling agent KH560, 70g of absolute ethanol, 6g of deionized water and 0.25g of ammonia into a beaker for ultrasonic treatment for 15min, then transfer to a three-necked flask, stir at 40°C for 24h, and then use Centrifugal cleaning with absolute ethanol for several times, drying, and grinding for later use; place a three-necked flask with constant speed stirring in an oil bath at a certain temperature, vacuumize and flush with nitrogen, and pour the above-mentioned modified pigment into 100g of tetrahydrofuran solution placed in an ultrasonic machine for ultrasonic treatment for 30 minutes, and then transferred to the flask together with 1g of lactide. When the lactide began to dissolve, 0.05g of stannous octoate was added dropwise, condensed and refluxed for a certain period of time. After the reaction, it was centrifuged and washed several times, and excess polylactic acid was washed away with chloroform, and finally put into ...

Embodiment 3

[0028] Put 2g of titanium dioxide, 1g of silane coupling agent KH560, 70g of absolute ethanol, 6g of deionized water and 0.25g of ammonia into a beaker for ultrasonic treatment for 15min, then transfer to a three-necked flask, stir at 40°C for 24h, and then use Centrifugal cleaning with absolute ethanol for several times, drying, and grinding for later use; place a three-necked flask with constant speed stirring in an oil bath at a certain temperature, vacuumize and flush with nitrogen, and pour the above-mentioned modified pigment into 100g of tetrahydrofuran solution placed in an ultrasonic machine for ultrasonic treatment for 30 minutes, and then transferred to the flask together with 1g of lactide. When the lactide began to dissolve, 0.05g of stannous octoate was added dropwise, condensed and refluxed for a certain period of time. After the reaction, it was centrifuged and washed several times, and excess polylactic acid was washed away with chloroform, and finally put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com