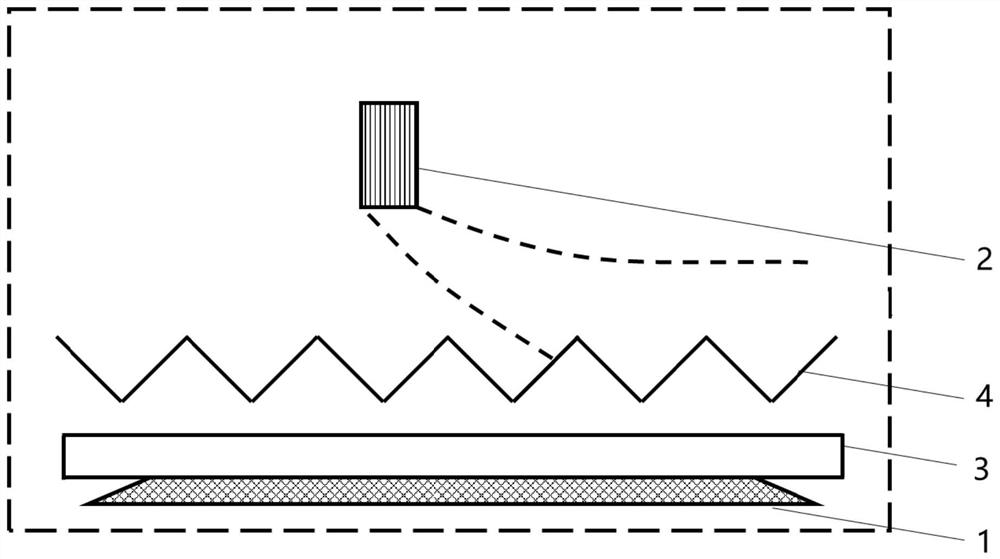

Method and equipment for enhancing wettability of thin film by utilizing high-frequency micro-vibration

A wettability and thin film technology, applied in the fields of material science and technology and thin film preparation, can solve the problems of film interface defects, low-voltage equipment production costs, etc., and achieve the effect of reducing production costs, large roughness, and reducing uncovered areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]1) Using DMF as a solvent, prepare CH with a concentration of 50% by mass 3 NH 3 PB 3 solution, the vibration frequency is 250kHz, the amplitude is 20nm, and a liquid film with a thickness of about 1000nm is prepared on the glass conductive substrate FTO with a substrate fluctuation of 250nm by a slit coating method;

[0040] 2) The liquid film is quickly dried at 10°C by air extraction method;

[0041] 3) Place the dried film on a hot plate at 70° C. for 15 minutes to obtain a transparent dark brown perovskite film on the glass conductive substrate FTO.

Embodiment 2

[0043] 1) Using DMSO as a solvent, prepare CH(NH with a mass percentage concentration of 40% 2 ) 2 PB 3 solution, the vibration frequency is 300kHz, the amplitude is 15nm, and a liquid film with a thickness of about 2000nm is prepared on the glass conductive substrate ITO with a substrate fluctuation of 200nm by spray deposition method;

[0044] 2) Using the air knife method, the liquid film is quickly dried at 30°C;

[0045] 3) Place the dried film on a hot plate at 100° C. for 10 minutes to obtain a transparent dark brown perovskite film on the glass conductive substrate ITO.

Embodiment 3

[0047] 1) Using a mixed solvent of DMF and NMP as a solvent, prepare a PCBM solution with a mass percentage concentration of 5%, the vibration frequency is 400kHz, and the amplitude is 20nm, and a perovskite film with a substrate fluctuation of 500nm is prepared by a scraping method. A liquid film with a layer thickness of about 3000nm;

[0048] 2) The liquid film is quickly dried at 50°C by air extraction method;

[0049] 3) Place the dried film on a hot plate at 120° C. for 8 minutes to obtain a transparent and bright dark brown perovskite film on the surface of the flexible conductive substrate ITO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com