Surface plasma resonance induced multilevel structure and modification method thereof

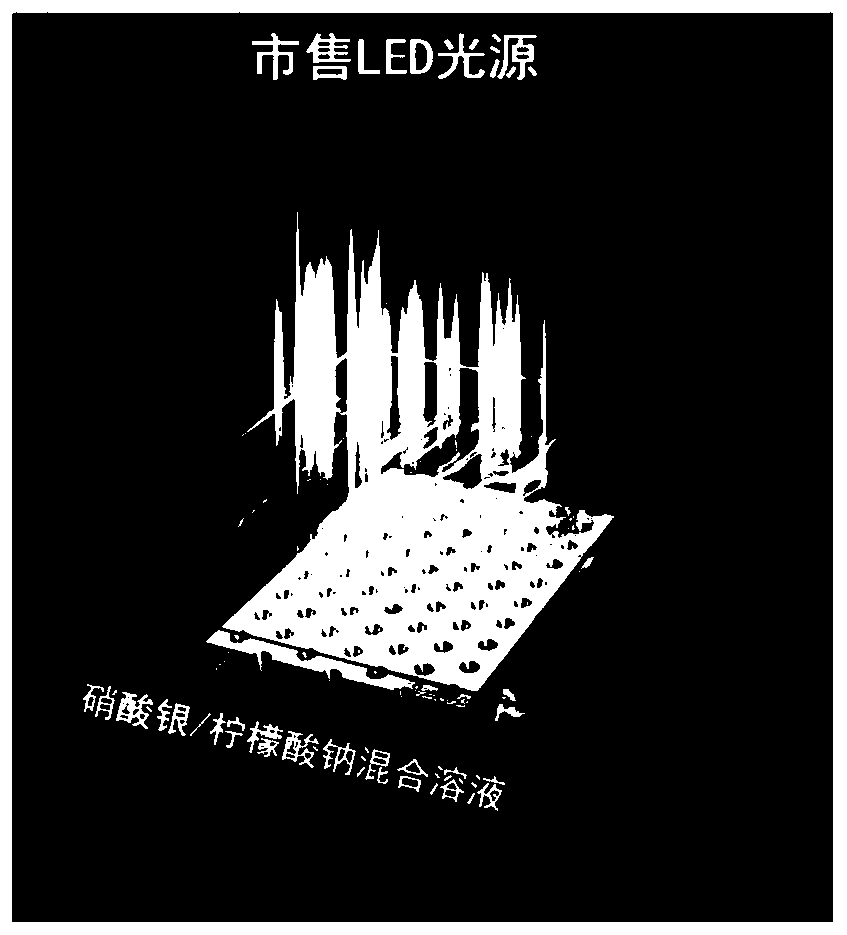

A technology of surface plasmon and modification method, applied in the field of multi-level structure induced by ionic resonance and its modification, to achieve the effect of avoiding equipment, high efficiency and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

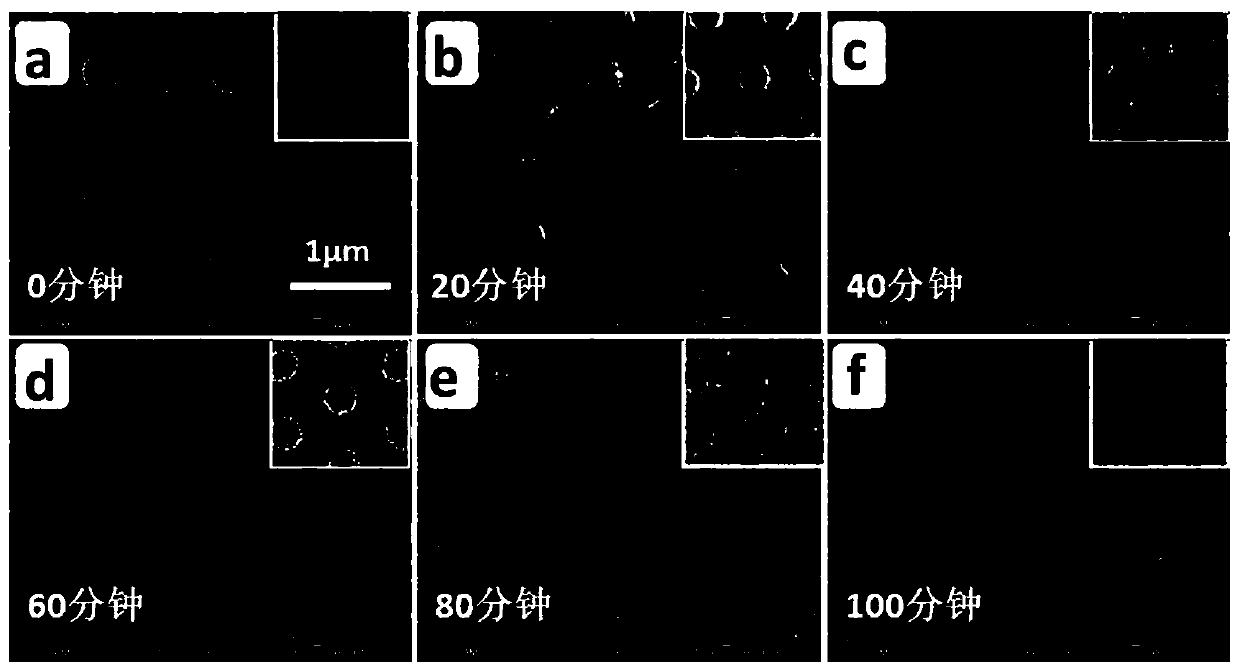

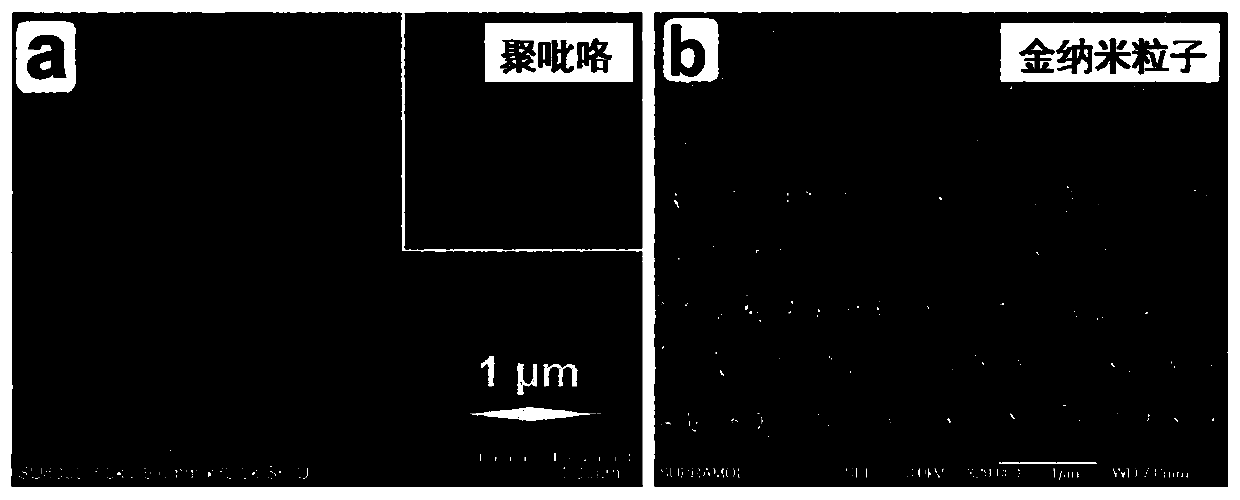

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of hydrophilic glass sheet

[0030] Use a glass knife to cut the glass sheet into a size of 2 cm in length and 1.5 cm in width, then place the glass sheet in a mixed solution of hydrogen peroxide and concentrated sulfuric acid (volume ratio 3:7), and heat it in a water bath at 80°C for 5 hours, then washed with deionized water for about 6 times, and dried with nitrogen to obtain a hydrophilic glass sheet.

Embodiment 2

[0031] Embodiment 2: the preparation of photoresist film

[0032] Spin-coat the photoresist collagen solution (BP212-37S, forward photoresist, purchased from Beijing Kehua Microelectronics Material Co., Ltd.) at a speed of 3000rpm with a desktop homogenizer onto the glass sheet after the hydrophilic treatment, and the spin-coating time is for 30 seconds, then put it in an oven at 88° C. for 2 hours, take it out and cool it down to room temperature naturally to obtain a glass substrate cured with a photoresist film with a thickness of 2 μm.

Embodiment 3

[0033] Embodiment 3: Preparation of polystyrene microsphere ethanol and deionized water dispersion

[0034] At room temperature, add 5 mL of deionized water dropwise to 3 mL of 5 wt % polystyrene microspheres with a diameter of 700 nm in water dispersion, sonicate at 100% power for 15 minutes, then centrifuge at 8900 rpm for 15 minutes, and absorb the supernatant Add 5 mL of deionized water to the lower layer of polystyrene microsphere sediment, ultrasonic treatment for 15 minutes, and centrifuge at 8900rpm for 15 minutes, repeat the above process of adding deionized water, ultrasonication, and centrifugation to the lower layer of polystyrene microsphere sediment. Operate 5 times; then add 5 mL of ethanol and deionized water mixed solution (volume ratio is 1:1) to the polystyrene microsphere sediment in the lower layer, sonicate for 15 minutes, then centrifuge with 8900rpm speed for 15 minutes, repeat the above-mentioned polystyrene microsphere sediment in the lower layer Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com