Method for preparing light rare earth hydride by high-temperature direct method

A light rare earth and hydride technology, applied in the direction of transition element hydrides, etc., to achieve safe and stable storage, simple operation, and improved production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

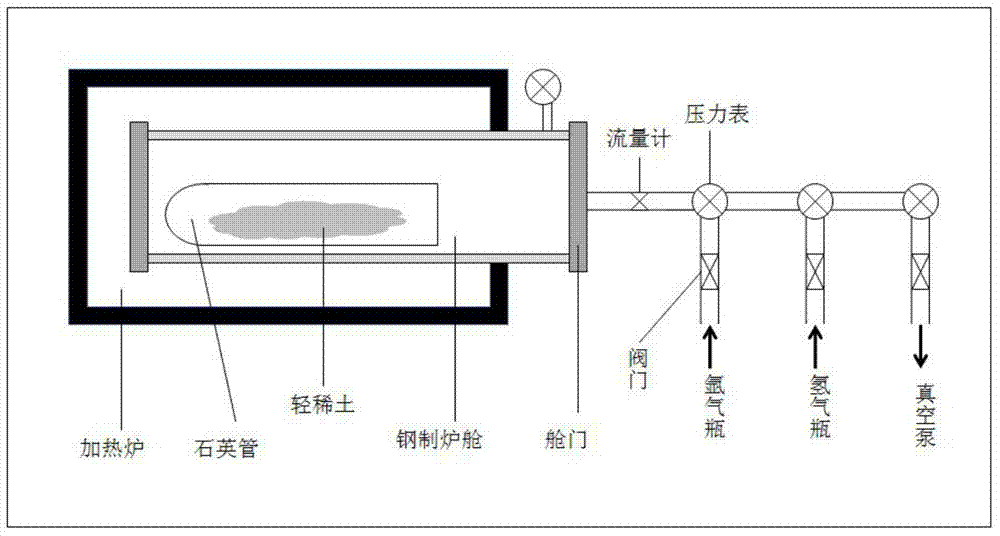

Embodiment 1

[0022] In a glove box filled with argon, 500 g of praseodymium with a purity of 99% was packed in a quartz glass test tube and sealed with a rubber stopper. The test tube is placed in a heating furnace cabin capable of evacuating, hydrogen and argon, and the cabin is set to an argon atmosphere in advance. Quickly pull out the rubber plug and close the furnace compartment. Keep the hydrogen and argon valves closed, open the exhaust valve, pump the furnace cabin pressure to a negative pressure of 0.026MPa; close the exhaust valve, open the argon valve to inflate the furnace cabin, close the argon valve, and open the exhaust valve Carry out vacuuming, repeat operation 2 times. Close all valves, quickly heat the furnace chamber to 360°C, open the hydrogen valve, input high-purity hydrogen into the reaction furnace, control the inflow of hydrogen at 770ml / min, and heat at a heating rate of 15°C / min for 20 minutes to 585°C Stop the temperature rise, keep the hydrogen flow rate con...

Embodiment 2

[0024] In a glove box filled with argon, 308 g of praseodymium with a purity of 99% was packed in a quartz glass test tube and sealed with a rubber stopper. The test tube is placed in a heating furnace cabin capable of evacuating, hydrogen and argon, and the cabin is set to an argon atmosphere in advance. Quickly pull out the rubber plug and close the furnace compartment. Keep the hydrogen and argon valves closed, open the exhaust valve, and pump the furnace cabin to a negative pressure of 0.030MPa; close the exhaust valve, open the argon valve to inflate the furnace cabin, close the argon valve, and open the exhaust valve Carry out vacuuming, repeat operation 2 times. Close all valves, quickly heat the furnace chamber to 375°C, open the hydrogen valve, input high-purity hydrogen into the reaction furnace, control the inflow of hydrogen at 580ml / min, and heat at a heating rate of 12°C / min for 18 minutes to 565°C Stop the temperature rise, keep the hydrogen flow rate constant...

Embodiment 3

[0026]In a glove box filled with argon, 1012 g of praseodymium with a purity of 99% was packed in a quartz glass test tube and sealed with a rubber stopper. The test tube is placed in a heating furnace cabin capable of evacuating, hydrogen and argon, and the cabin is set to an argon atmosphere in advance. Quickly pull out the rubber plug and close the furnace compartment. Keep the hydrogen and argon valves closed, open the exhaust valve, pump the furnace cabin pressure to a negative pressure of 0.019MPa; close the exhaust valve, open the argon valve to inflate the furnace cabin, close the argon valve, and open the exhaust valve Carry out vacuuming, repeat operation 3 times. Close all valves, quickly heat the temperature of the furnace chamber to 395°C, open the hydrogen valve, input high-purity hydrogen into the reaction furnace, control the inflow of hydrogen to 1318ml / min, and heat at a heating rate of 10°C / min for 25 minutes to 605°C Stop the temperature rise, keep the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com