Chitosan multilayered gel balls and preparation method thereof

A technology of chitosan gel balls and multi-layer gels, applied in the field of material science, can solve problems such as unsatisfactory control of layer thickness, restrictions on the research and development of chitosan gel with multi-layer structures, and complex pretreatment. To achieve the effect of easy operation, simple operation and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

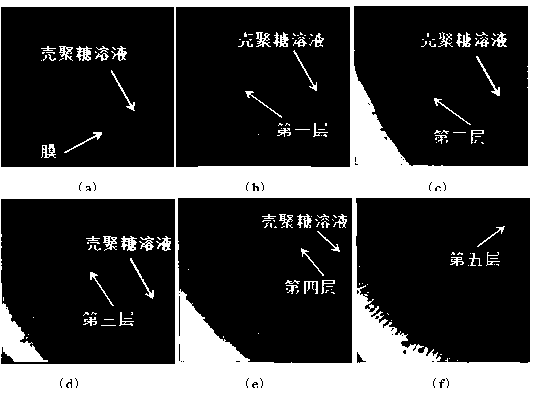

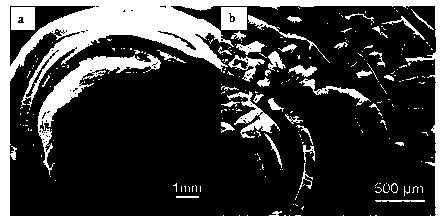

[0040] Add 1 mL of concentrated hydrochloric acid to 99 mL of deionized water, and stir evenly to obtain a hydrochloric acid solution with a volume fraction of 1% (v / v). Add 3.5g molecular weight 10 5 The chitosan was stirred evenly to obtain a chitosan-acetic acid mixed solution with a chitosan concentration of 3.5% (w / v). Add 2 g of sodium alginate powder into 100 mL of deionized water, stir at room temperature until completely dissolved, and obtain a sodium alginate solution with a concentration of 2% (w / v). Take a drop of chitosan solution with a dropper and add it dropwise to the sodium alginate solution, so that the chitosan droplet is completely immersed in the sodium alginate solution, and let it stand for 4 hours to obtain a chitosan wrapped by a polyelectrolyte film. The pellets are taken out with a medicine spoon and the excess sodium alginate solution on the surface is washed away with deionized water to obtain transparent chitosan pellets. Soak chitosan transpar...

Embodiment 2

[0042] Add 1mL of glacial acetic acid to 99mL of deionized water, stir evenly to obtain an acetic acid solution with a volume fraction of 1% (v / v), add 4g of acetic acid with a molecular weight of 2×10 5 The chitosan was stirred evenly to obtain a chitosan-acetic acid mixed solution with a chitosan concentration of 4% (w / v). Add 3 g of sodium alginate powder into 100 mL of deionized water, stir at room temperature until completely dissolved, and obtain a sodium alginate solution with a concentration of 3% (w / v). Take a drop of chitosan solution with a dropper and add it dropwise to the sodium alginate solution, so that the chitosan droplet is completely immersed in the sodium alginate solution, and let it stand for 5 hours to obtain a chitosan wrapped by a polyelectrolyte film. The pellets are taken out with a medicine spoon and the excess sodium alginate solution on the surface is washed away with deionized water to obtain transparent chitosan pellets. Soak chitosan transpar...

Embodiment 3

[0044]Add 2mL of glacial acetic acid to 98mL of deionized water, stir evenly to obtain an acetic acid solution with a volume fraction of 2% (v / v), add 3.5g of acetic acid with a molecular weight of 3×10 5 The chitosan was stirred evenly to obtain a chitosan acetic acid solution with a chitosan concentration of 3.5% (w / v). Add 2 g of sodium alginate powder into 100 mL of deionized water, stir at room temperature until completely dissolved, and obtain a sodium alginate solution with a concentration of 2% (w / v). Take a drop of chitosan solution with a dropper and add it dropwise to the sodium alginate solution, so that the chitosan droplet is completely immersed in the sodium alginate solution, and soak for 6 hours to obtain a small chitosan wrapped by a polyelectrolyte film. The ball is taken out with a medicine spoon and the excess sodium alginate solution on the surface is washed away with deionized water to obtain a chitosan transparent bead. Soak chitosan transparent beads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com