Method for preparing ethylene-trifluorochlor oethylene copolymer porous membrane

A technology of chlorotrifluoroethylene and copolymers, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor mechanical properties and low porosity, and achieve high mechanical strength, high porosity, The effect of widening the concentration selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

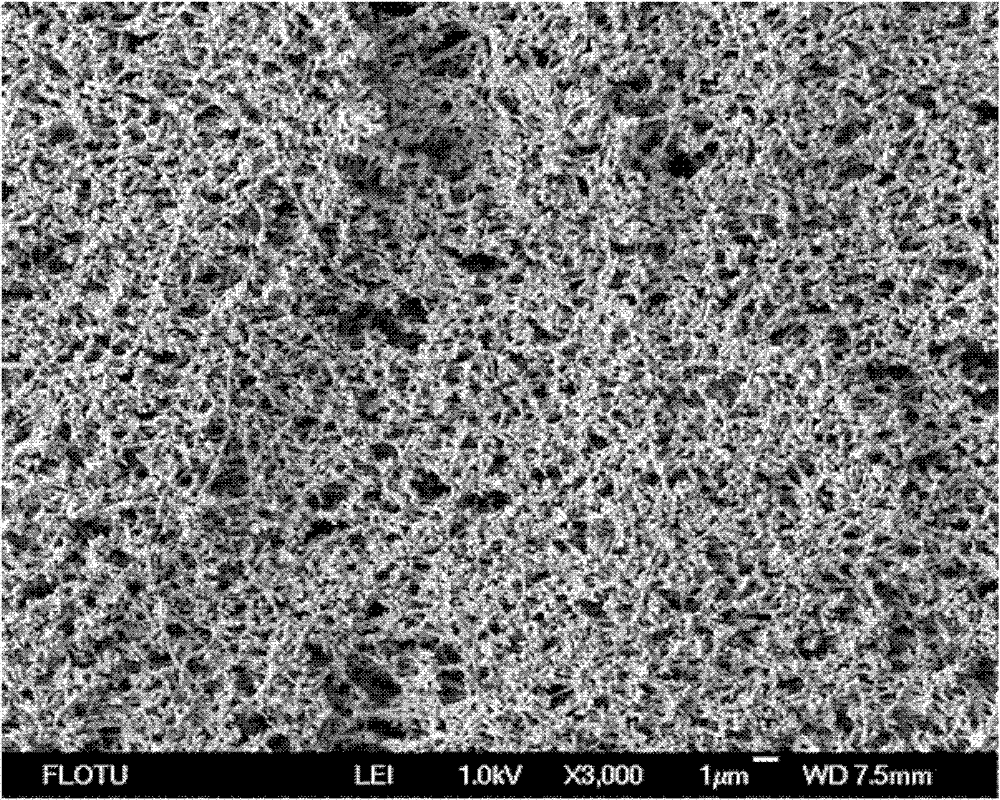

[0036] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percent composition of ethylene-trifluoroethylene copolymer is 10wt%, and the mass percent composition of diethylphthalate is 90 wt%, put it into a high-temperature stirred tank and heat up to 240 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to solidify the solution into a film by phase separation. The cooling liquid was a water bath. The cured flat film was extracted with ethanol and dried.

[0037]The cross-section of the membrane is a uniform sponge-like structure with a porosity of 84% and a breaking strength of 3.25MPa.

Embodiment 2

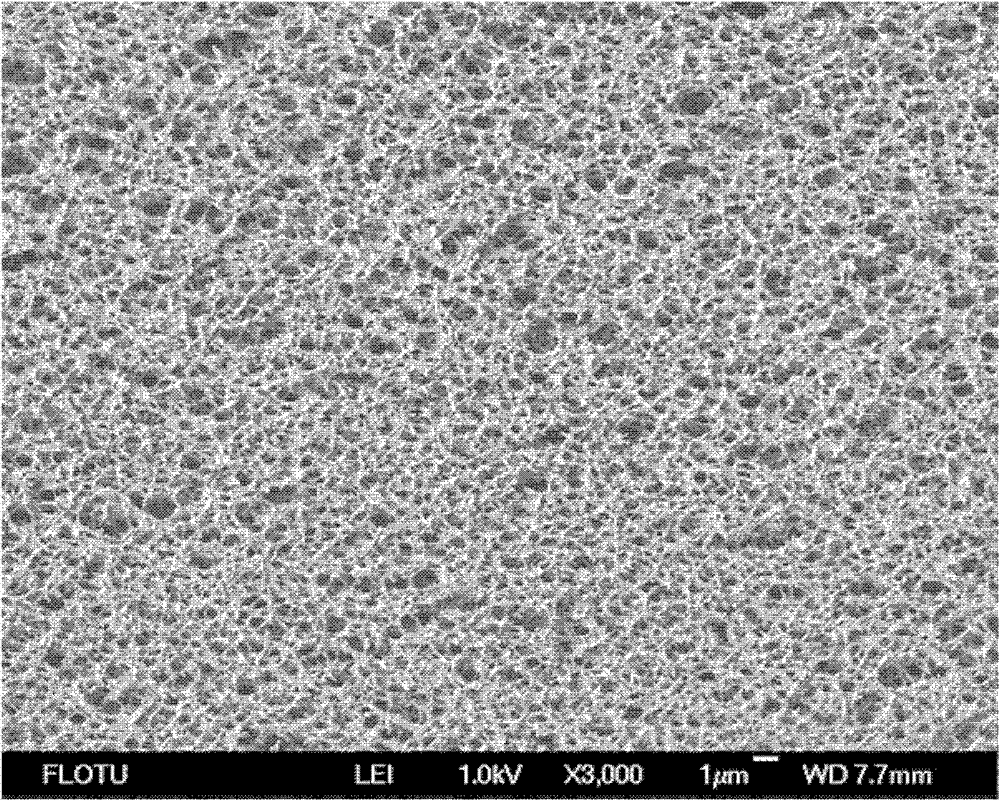

[0039] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percent composition of ethylene-trifluoroethylene copolymer is 28wt%, and the mass percent composition of diethylphthalate is 72 wt%, put it into a high-temperature stirred tank and heat up to 240 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to solidify the solution into a film by phase separation. The cooling liquid was a glycerol bath. The cured flat film was extracted with ethanol and dried.

[0040] The cross-section of the membrane is a uniform sponge-like structure with a porosity of 71% and a breaking strength of 10.58MPa.

Embodiment 3

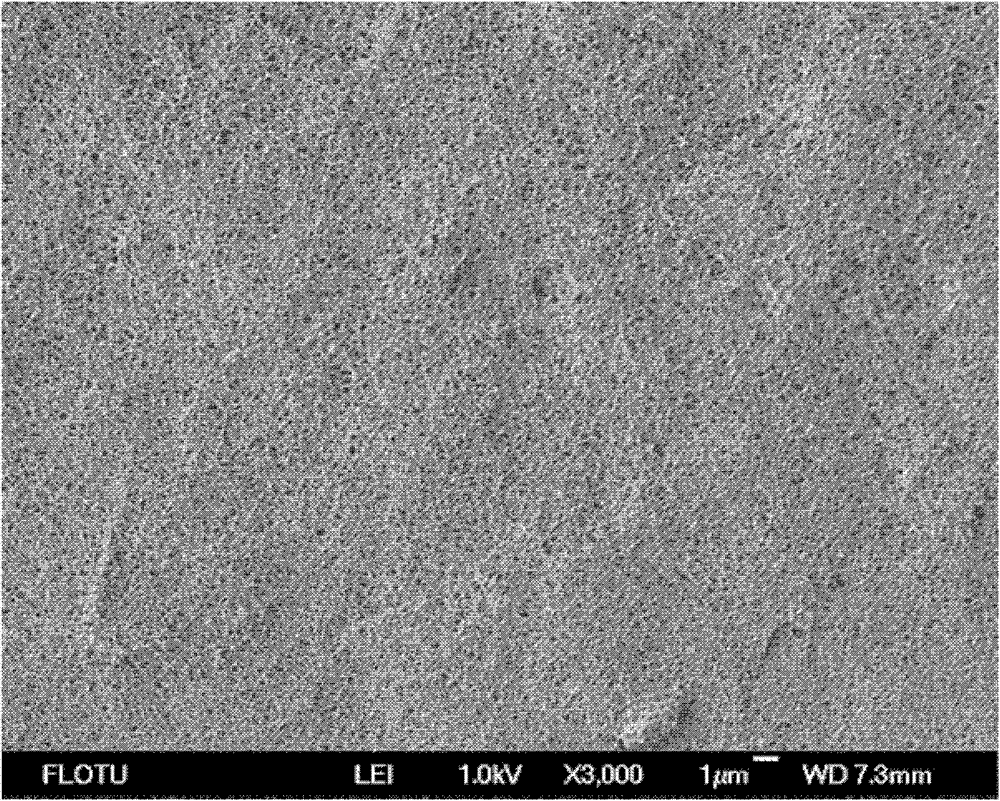

[0042] With ethylene-chlorotrifluoroethylene copolymer and diethyl phthalate, its component is that the mass percent composition of ethylene-trifluoroethylene copolymer is 60wt%, and the mass percent composition of diethylphthalate is 40 wt%, put it into a high-temperature stirred tank and heat up to 250 degrees Celsius, stir and mix evenly to form a polymer homogeneous solution, and let it stand for 24 hours. Then the polymer homogeneous solution was directly hang-coated on the support net to form a flat film with a film thickness of 200 μm, and entered into a cooling liquid bath at 30°C to solidify the solution into a film by phase separation. The cooling liquid was a water bath. The cured flat film was extracted with ethanol and dried.

[0043] The cross-section of the membrane is a uniform sponge-like structure with a porosity of 31% and a breaking strength of 14.59MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com