Polyester with high molecular weight and weak crystallinity and its preparation method and application

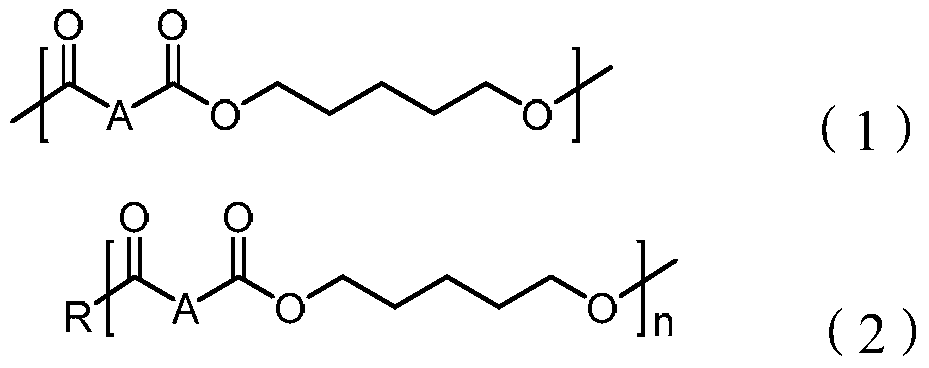

A high-molecular-weight and crystalline technology, applied in polyester and its preparation, high-molecular-weight and weakly crystalline polyester and its preparation field, can solve the problems of low molecular weight and poor mechanical properties of homopolyester, and achieve weak crystallinity, The effect of good flexibility and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

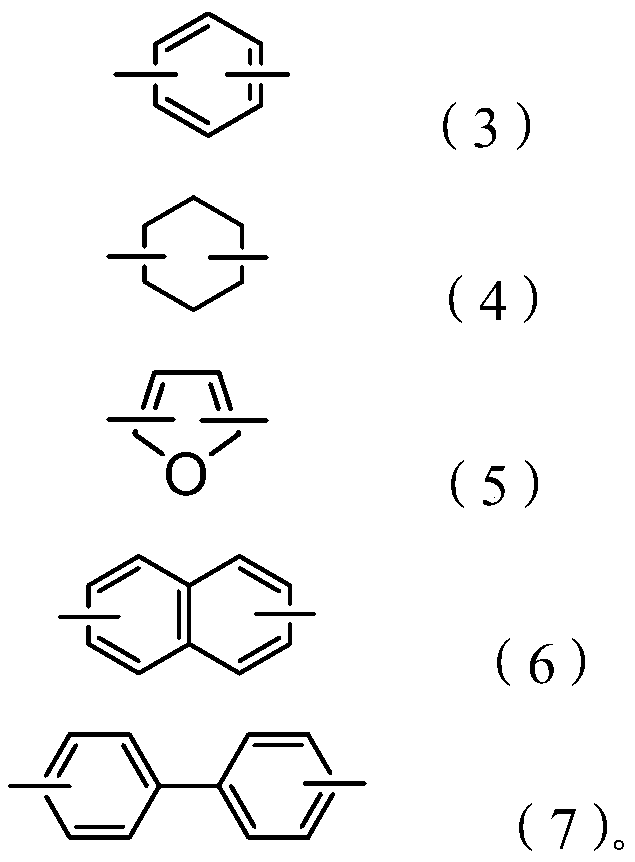

Method used

Image

Examples

Embodiment 1

[0044] (1) Add isophthalic acid (0.375mol, 58.53g), 1,5-pentanediol (1.0mol, 104.15g) and titanium dioxide-silica-polyvinylpyrrolidone composite catalyst (1.5 mmol, 114 mg), with an alkyd ratio of 2.7, reacted at 200°C for 1 hour, 220°C for 1 hour, and 230°C for 1 hour to obtain an esterified product with an esterification rate of 98.9%;

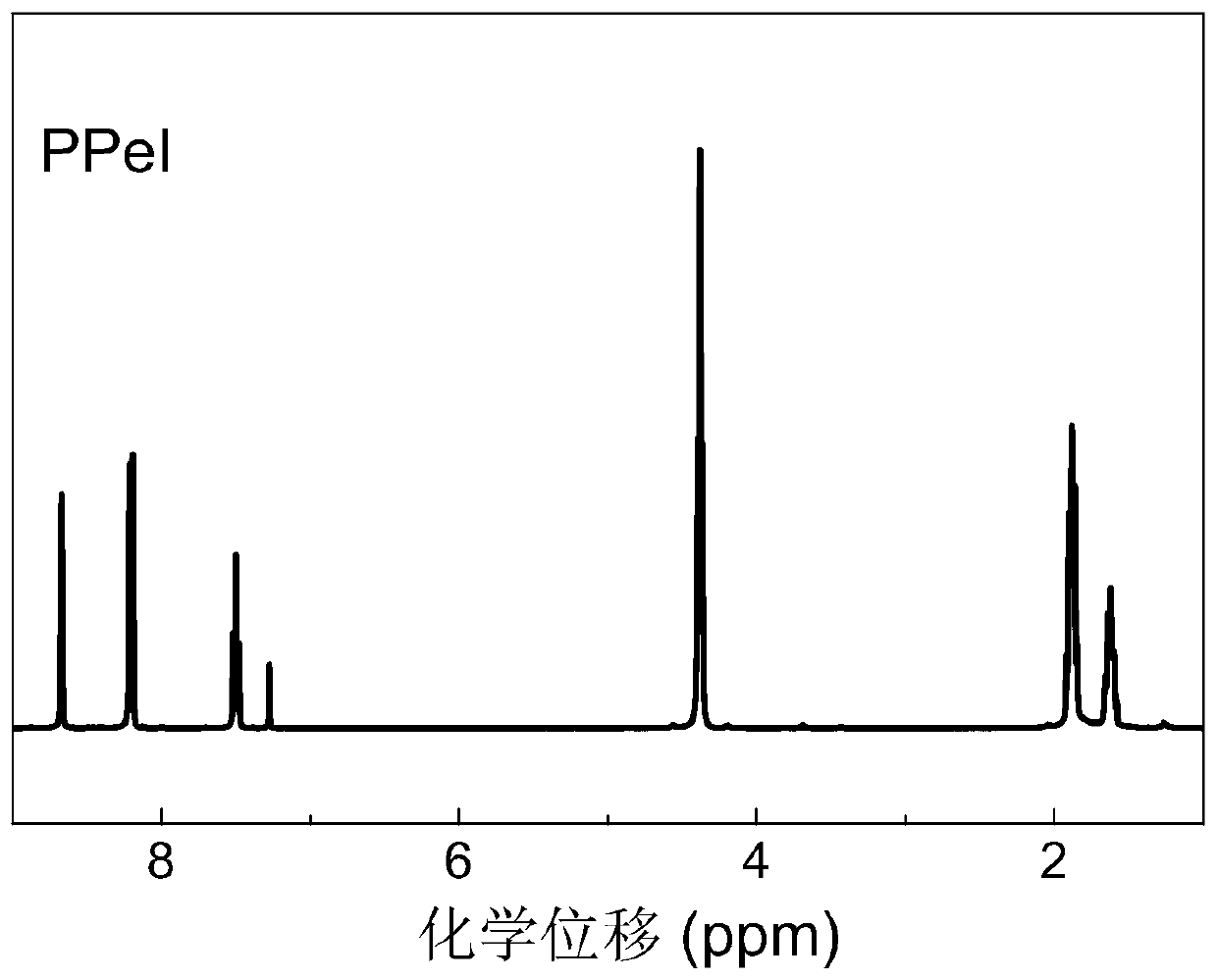

[0045] (2) No further catalyst is added to the esterification product obtained in step (1). Under the condition of about 120Pa, the reaction is carried out at 230°C for 1 hour, at 240°C for 1 hour, at 250°C for 1 hour, and at 260°C for 0.5 hour, remove excess 1,5-pentanediol and a small amount of oligomers to obtain polypentylene isophthalate, abbreviated as PPeI, and its H NMR spectrum is as follows figure 1 shown.

[0046] After testing, the intrinsic viscosity of PPeI prepared in this example is 0.81dL / g, the glass transition temperature is -13.5°C, and there is no obvious melting and crystallization peak and melting point; the tensile m...

Embodiment 2

[0048] (1) Add 2,5-furandicarboxylic acid (0.375mol, 58.53g), 1,5-pentanediol (0.75mol, 78.11g) and n-butyl titanate (0.375mmol, 128mg) into a 250mL four-necked flask ), with an alkyd ratio of 2, reacted at 200°C for 1 hour, at 220°C for 1 hour, and at 230°C for 1.5 hours to obtain an esterified product with an esterification rate of 98.9%;

[0049] (2) Add isopropyl titanate (0.375mmol, 106mg) to the esterification product obtained in step (1), and react at 230°C for 1 hour at about 140Pa, 1 hour at 240°C, and 250°C React for 1 hour at 260°C for 1 hour to remove excess 1,5-pentanediol and a small amount of oligomers to obtain polypentylene-2,5-furandicarboxylate, abbreviated as PPeF.

[0050] After testing, the intrinsic viscosity of PPeF prepared in this example is 0.84dL / g, the glass transition temperature is 21.9°C, and there is no obvious melting and crystallization peak and melting point; the tensile modulus is 4.2MPa, the tensile strength is 11.2MPa, and the elongation ...

Embodiment 3

[0052] (1) Add terephthalic acid (0.5mol, 78.04g), xylitol (5mmol, 0.761g), 1,5-pentanediol (0.75mol, 78.11g) and titanium- Phosphorus composite catalyst (306mg, Nanjing Nengde New Material Technology Co., Ltd., TCAIA10), with an alkyd ratio of 1.5, was reacted at 200°C for 1 hour, at 220°C for 1 hour, and at 230°C for 3 hours to obtain an esterification product, The esterification rate reaches 97.0%;

[0053] (2) No further catalyst is added to the esterification product obtained in step (1). Under the condition of about 120 Pa, the reaction is carried out at 230° C. for 1 hour, at 240° C. for 1 hour, at 250° C. for 1.5 hours, and at 260° C. for 1 hour. Hours, remove excess 1,5-pentanediol and a small amount of oligomers to obtain xylitol-branched polypentylene terephthalate, abbreviated as PPeT-b.

[0054] After testing, the intrinsic viscosity of PPeT-b prepared in this example is 0.78dL / g, the glass transition temperature is 13.5°C, the melting crystallization peak temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com