One-pile-one-column connecting structure adopting reverse building method and construction method of one-pile-one-column connecting structure

A technology of connecting structures and reverse method, which is applied in the direction of foundation structure engineering, columns, excavation, etc., can solve the problems of eccentric force of one column and one pile, large pile position of measurement setting-out error, affecting project quality and structural safety, etc., to achieve The connection is firm, the welding area is increased, and the effect of increasing the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

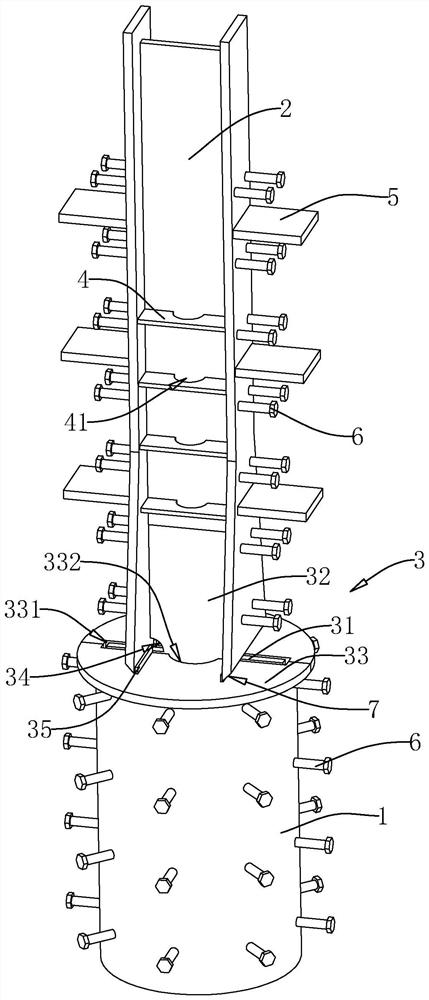

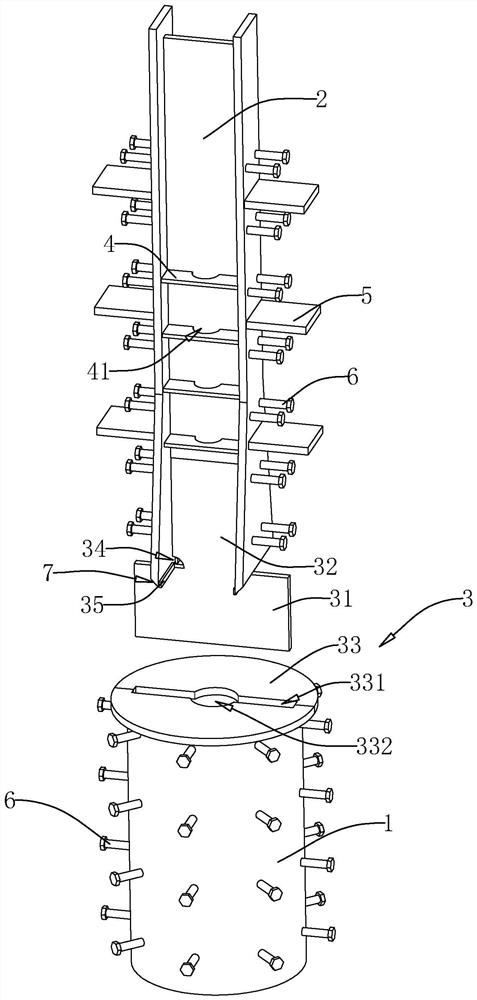

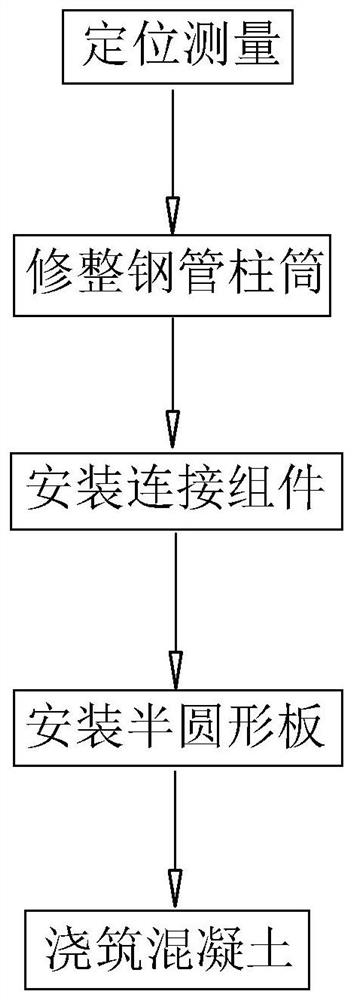

[0037] Contraction below Figure 1-3 Further detailed description of the present application.

[0038] The present application discloses an inverse method, a column, a column, a column, and its construction method thereof. Refer figure 1 , An inverse method of a column is connected to the steel pipe cylinder 1 vertically disposed inside the foundation pit, and the steel bone column 2 is vertically mounted on the upper end of the steel pipe cylinder 1, and when the steel pipe cylinder 1 is disposed in the group After the pits, the steel pipe cylinder 1 is filled in the concrete. The steel osteo column 2 is H-type steel, and H-type steel comprises an H-type steel web and a pair of H-type steel wing plates, steel bone column 2 and steel bone column 2 and A connecting assembly 3 is provided between the steel pipe cylinder 1, and the connecting assembly 3 is fixedly coupled to the steel bone column 2 and the steel pipe column 1, and the steel pipe cylinder 1 produces a certain error aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com