Formwork support system and construction method of cast-in-place concrete beam-slab structure

A technology for supporting concrete beams and formwork, which is applied in the field of construction engineering, can solve the problems such as the inability to share beam formwork support poles, the difficulty of erecting beam plate formwork support poles, the difficulty of connecting poles and horizontal poles, and the like. The effect of easy quality control, consumption saving and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

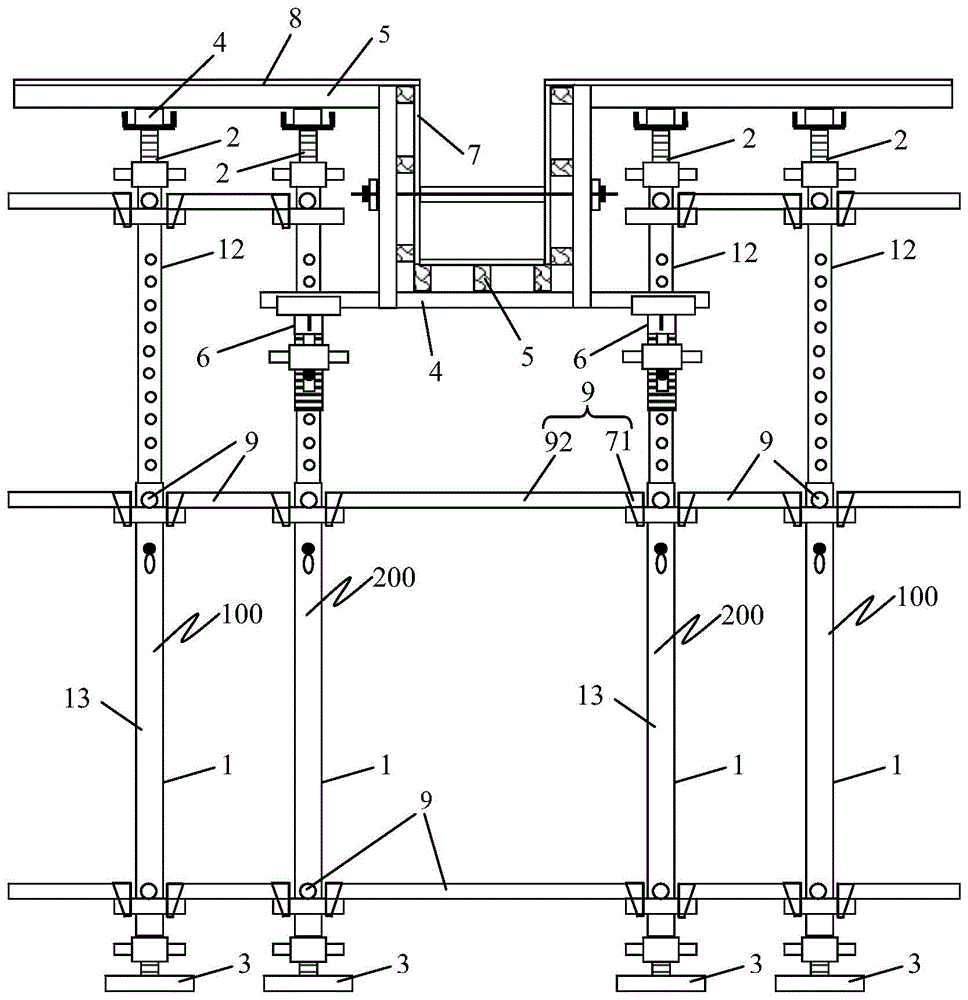

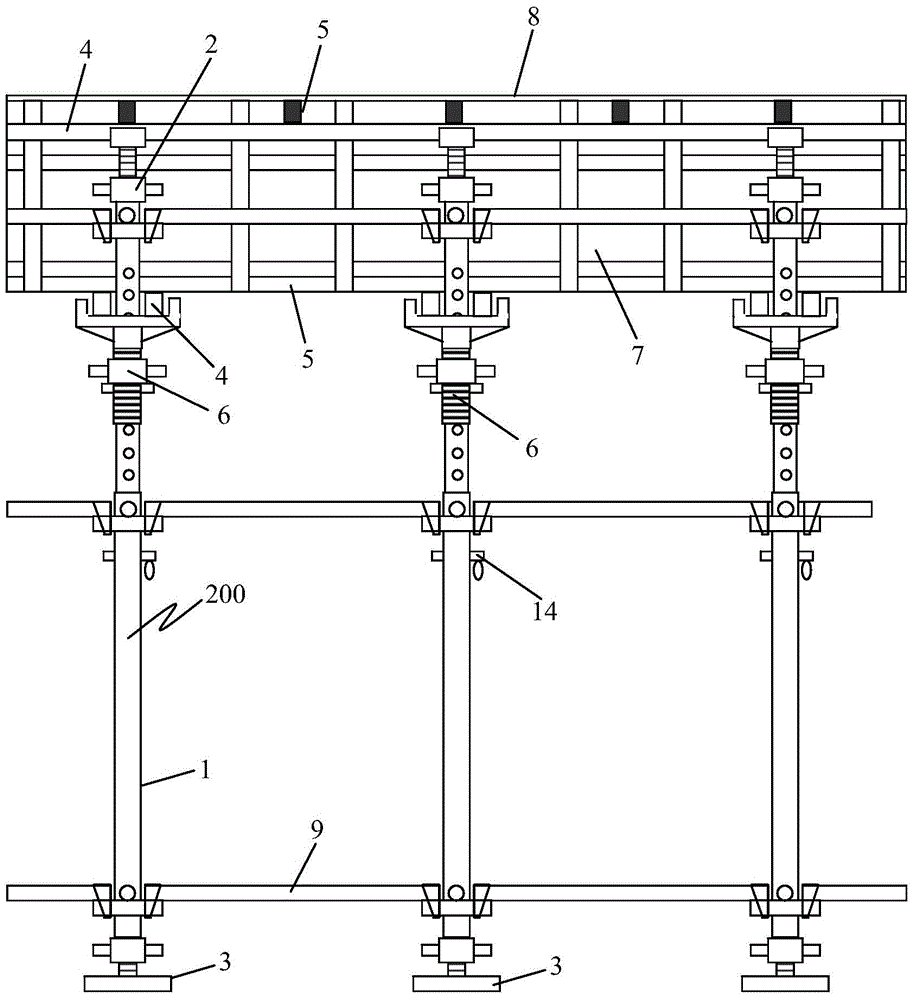

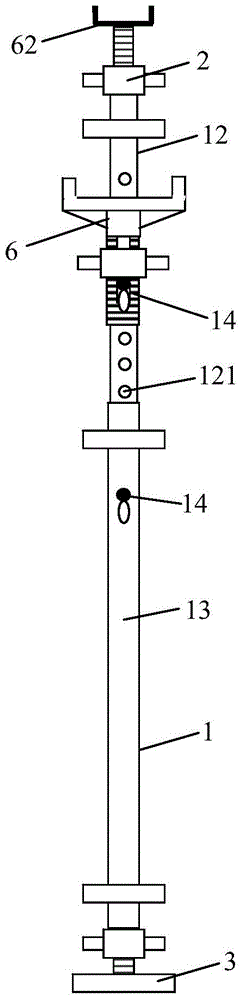

[0042] see Figure 1 to Figure 10 As shown, the present invention is a formwork support system for cast-in-place concrete beam-slab structures. The support system includes multiple sets of support rod assemblies, and each set of support rod assemblies includes: a first support rod assembly 100 and a second support rod assembly 200; The first support rod assembly 100 includes a telescopic support pole 1, an adjustable jack 2, an adjustable base 3, a joist 4, and a joist 5; the telescopic support pole 1 is covered with a plurality of trays 11. The adjustable jacking 2 is set on the top of the telescopic support pole 1, and the adjustable base 3 is set on the bottom of the telescopic support pole 1;

[0043] The second support rod assembly 200 is provided with a girder 6 on the telescopic support pole 1 of the first support rod assembly 100; the joist 4 is arranged on the girder 6 or on the adjustable jacking 2 , the joists 5 are arranged on the joists 4; the second support rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com