Pneumatic anchor rod hammer drill

A technology of rock drills and air legs, applied in the field of rock drills, can solve the problems of difficult control, inconvenient operation, and difficult control of the staff, and achieve the effects of improving overall stability, convenient operation, and reducing strong vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

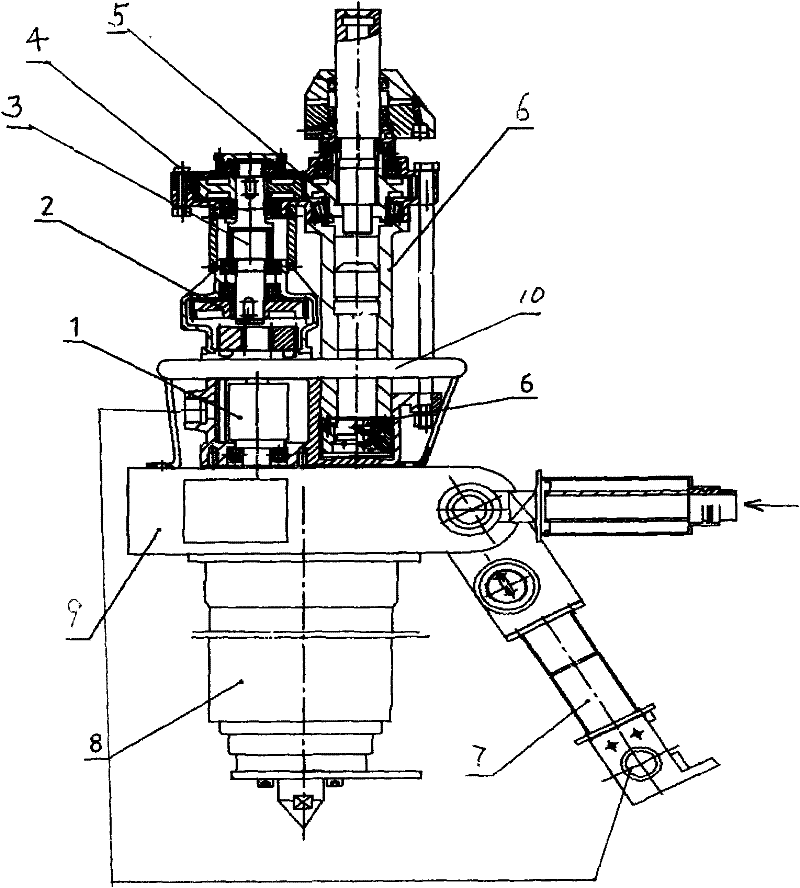

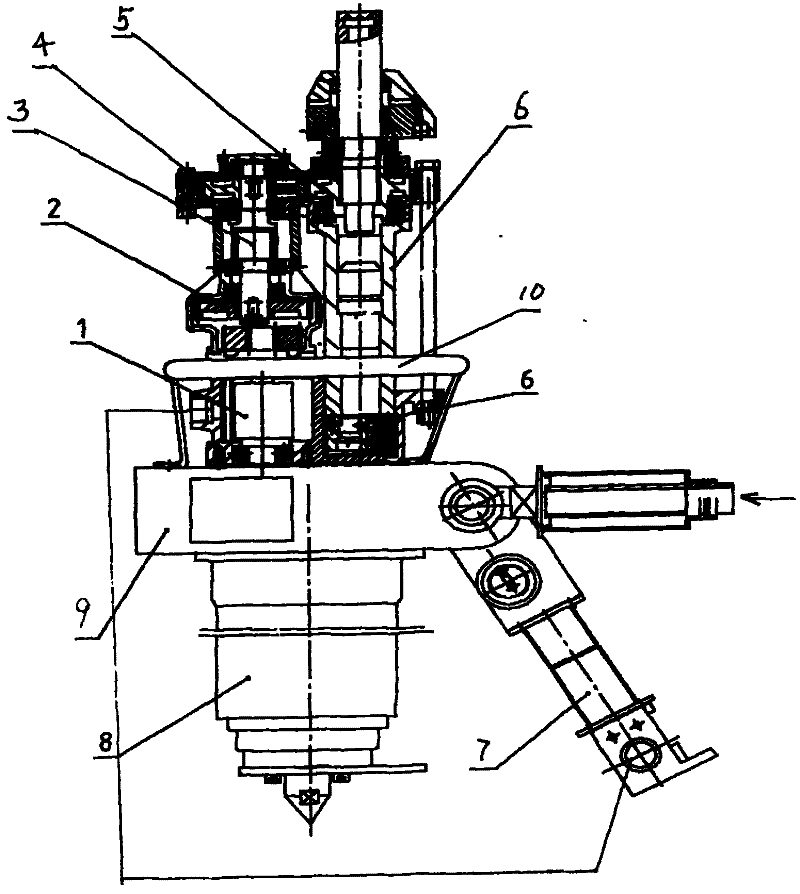

[0010] Such as figure 1 As shown, the utility model includes a rock drill body composed of a rock drill shell, an impact part 6 in the shell, an air leg 8, and an operating arm 7, and a rotating part composed of a variable speed gearbox 2 and an air motor 1. The shank of the impact part 6 A gear 5 is processed on the sleeve, an extension shaft 3 is connected to the power output shaft of the transmission gearbox 2, and a transmission gear 4 is installed on the extension shaft 3, and the transmission gear 4 meshes with the shank gear 5; the rotating part is connected with the shell of the rock drill 3. The support axis of the air leg 8 is arranged on the center of gravity of the overall weight of the rock drill; the air intake pipe of the wind motor 1 is directly connected to the control arm 7. on the valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com