Steel pipe truss hinged joint device

A technology of steel pipe trusses and joints, which is applied in the field of steel pipe truss devices for construction engineering, which can solve the problems that the bearing capacity and stiffness of hinged joints cannot meet the requirements, and the center of gravity of the force cannot meet at one point, so as to improve the bearing capacity and stiffness and avoid eccentricity force, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

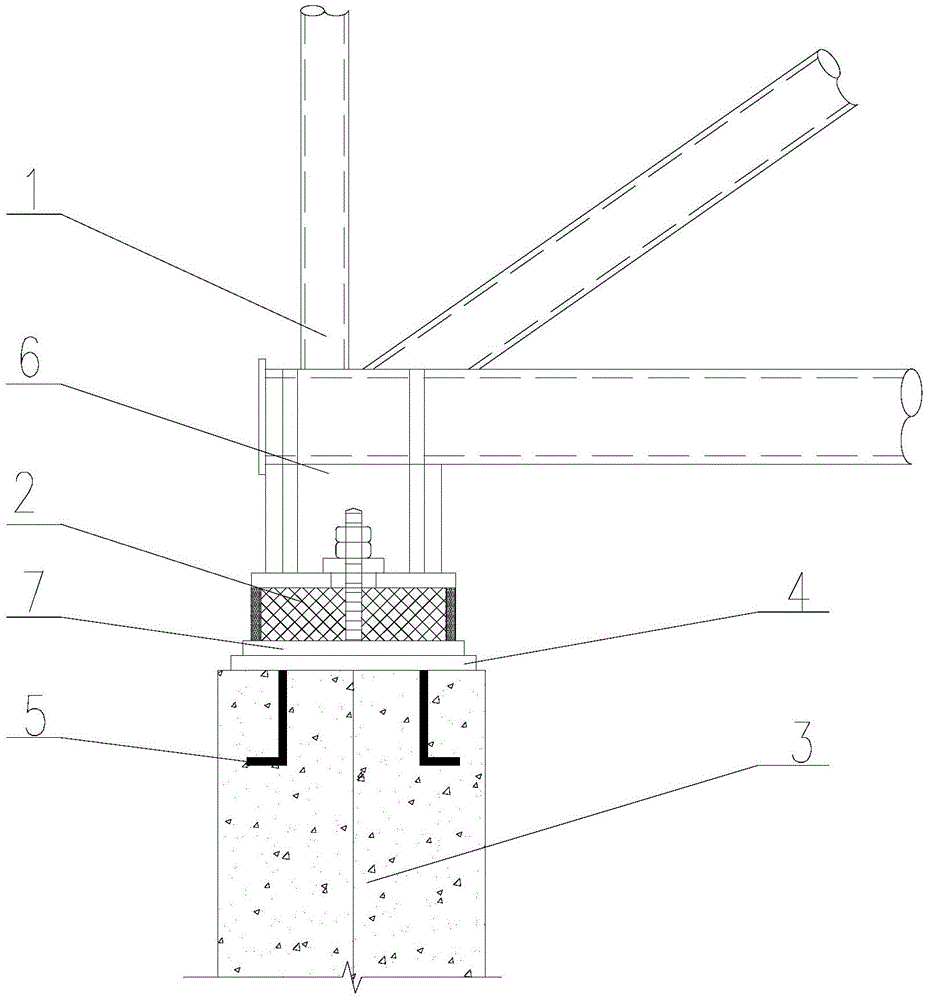

[0014] see figure 1 , a steel pipe truss hinge joint device, the hinge joint device is mainly composed of a steel pipe truss 1, a rubber pad 2, embedded parts and a concrete fixing device 3, the embedded parts include a horizontal steel plate 4 and a vertically welded and fixed horizontal steel plate 4 Steel bar 5, the steel bar 5 is built into the concrete fixing device 3, the steel pipe truss 1 is a three-sided steel pipe truss, the lower end of the steel pipe truss 1 is provided with a support 6 integrally formed with the steel pipe truss 1, and the bottom end of the support 6 is provided with a support The transition plate 7, the rubber pad 2 is installed between the support 6 and the support transition plate 7 through anchor bolts, the outer periphery of the rubber pad 2 is provided with foam plastic plugging, and the support transition plate 7 is fixed on the horizontal steel plate by welding 4 upper end.

[0015] The support transition plate 7 and the horizontal steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com