Prestressed carbon fiber-reinforced plastic plate anchorage device and manufacturing method thereof

A technology of reinforced plastics and manufacturing methods, applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problems of prestress loss, sheet corrosion, loose connectors, etc., to achieve simple design, good ductility and deformation ability, Reasonable effect of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

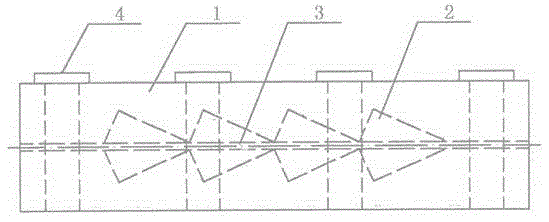

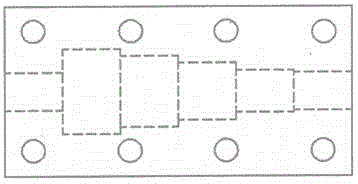

[0025] like Figure 1-2 The production method is as follows: the CFRP sample is ground along the direction of ±45 degrees, and the surface is cleaned with acetone after grinding; the outer surface of the steel plate and the inner surface of the groove are cleaned 2-3 times with acetone. Clean all dust and impurities; apply mold release agent evenly inside the wedge-shaped groove of the steel plate, and its thickness should be kept moderate; slowly pour the prepared epoxy resin into the wedge-shaped groove of the two steel plates, Make the groove full and uniform; quickly cover one of the steel plates on the other steel plate, and the speed of this action should be agile to prevent the epoxy resin inside the steel plate groove from spilling; use tape to follow the gap between the two steel plates Wind 2-3 turns to prevent the leakage of epoxy resin inside the steel plate; use a wrench to tighten the bolts on the steel plate; use a wallpaper knife to cut off the tape at the entr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com