Punching bar and die for secondary preformation of inner hexagonal cylinder head and forming method

A forming method and pre-forming technology, applied in the direction of manufacturing tools, bolts, connecting components, etc., can solve the problems of low service life of hexagon socket punches, large deformation of the head, affecting the stability of the production process, etc., and reduce the operation time. The effect of replacement time, increased service life, and reduced mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0020] The embodiment of the present invention is mainly aimed at the production of hexagon socket head cap screws by multi-station cold heading of M5~M24, and is mainly used for the production of general-purpose hexagon socket head cap screw basic parts by multi-station cold heading.

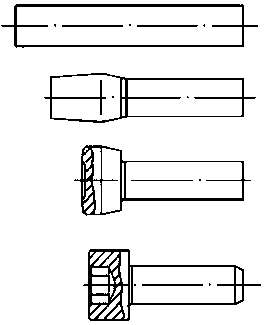

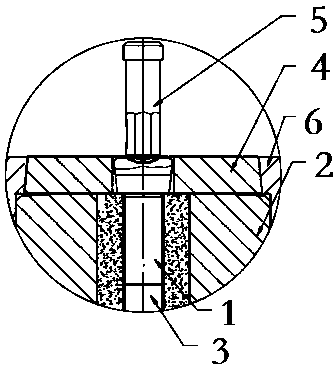

[0021] In this embodiment, the forming method of the hexagonal cylindrical head includes a first preforming step, a second preforming step, and an extrusion forming step. figure 1 Shown is the diagram of the deformation state of the workpiece in the forming method. From top to bottom, it is the first, second, third, and fourth diagrams, which respectively represent the state of the workpiece in different steps.

[0022] The first preforming step consists of cutting the disk raw material (such as figure 1 In the first picture), the pinch is sent to the first preforming die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com