Asphalt mortar forming, measuring device and test method for dynamic shear parameters of asphalt mortar

A technology for asphalt mortar and parameter testing, which is applied in the direction of applying stable shear force to test the strength of materials and the preparation of test samples. It can solve the problems of affecting test results, inability to perform performance tests, and easy damage of asphalt mortar specimens. , to achieve the effect of economical operation, ensuring accuracy and reliability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

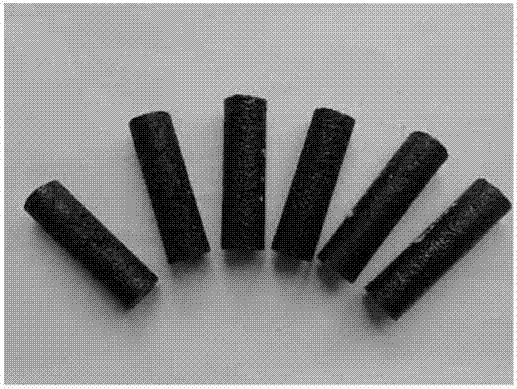

specific Embodiment approach 1

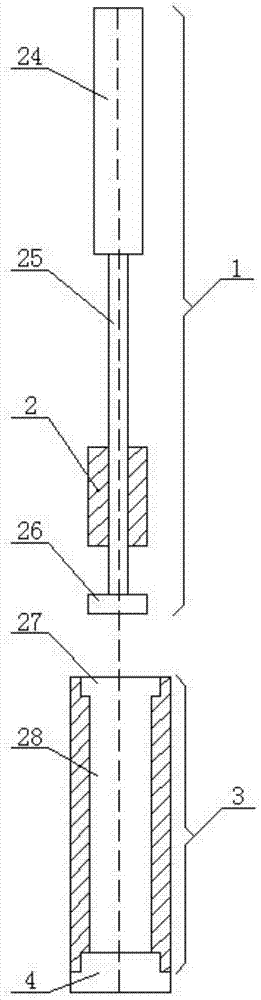

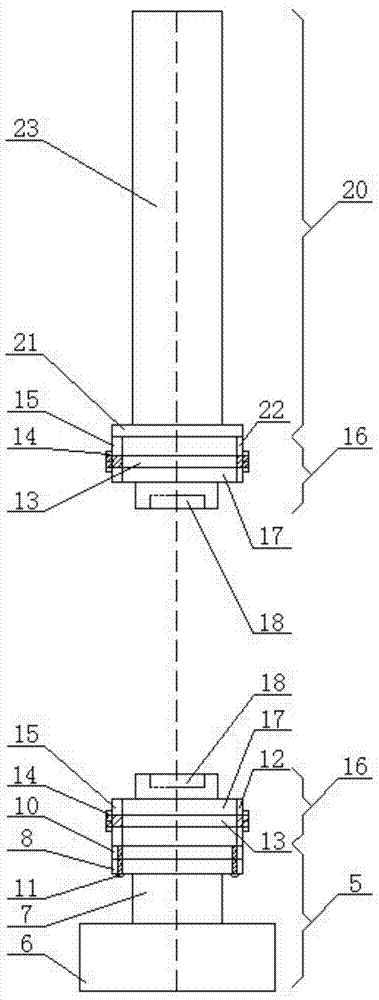

[0050] The asphalt mortar molding device of the present embodiment, such as figure 1 As shown, its composition includes a guide rod 1, a test mold 3 and a base 4. One end of the test mold 3 is oppositely provided with a guide rod 1, and the other end is fitted with the base 4, and the guide rod 1, the test mold 3 and the base 4 coaxial setup; where,

[0051] The guide rod 1 includes a hand-held block 24, a connecting rod 25 and a compacting head 26, the hand-held block 24 and the compacting head 26 are respectively coaxially connected to the two ends of the connecting rod 25 to form an integrated structure, and the connecting rod 25 Outer wall sliding set real hammer 2;

[0052] The interior of the test mold 3 has a hollow compaction cavity 28, the two ends of the compaction cavity 28 communicate with the clamping grooves 27 respectively, and the compaction cavity 28 and the two clamping grooves 27 are arranged coaxially.

specific Embodiment approach 2

[0053] Different from Embodiment 1, in the asphalt mortar forming device of this embodiment, the hand-held block 24, the connecting rod 25 and the compacting head 26 are all cylindrical and made of metal materials; the diameters are 12mm, 6mm and 12mm, and the heights are 200mm, 355.5mm and 20mm respectively; wherein, the length of the connecting rod (25) is 374.5mm.

specific Embodiment approach 3

[0054] Different from Embodiment 1 or Embodiment 2, in the asphalt mortar molding device of this embodiment, the clamping groove 27 and the compaction cavity 28 of the test mold 3 are both cylindrical cavities; the internal diameter of the clamping groove 27 is 16 mm, and the depth The inner diameter of the compaction cavity 28 is 12mm, and the depth is 56mm; and the test mold 3 is made of metal material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com