Pavement material direct tensile test apparatus with eccentric tension avoided and method thereof

A pavement material, tensile test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as inability to use, inaccurate test data, etc., and achieve reliable test data, accurate test results, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

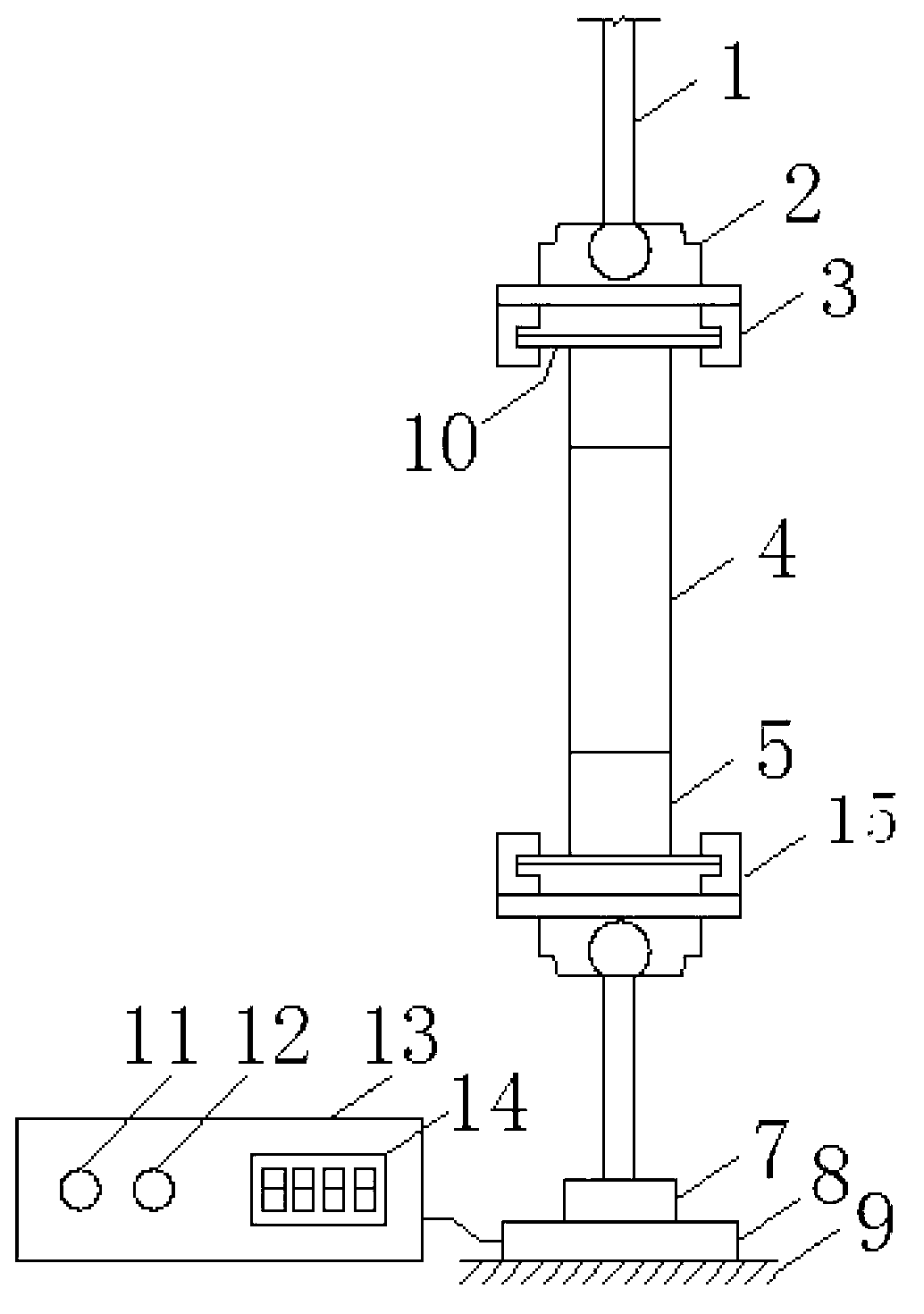

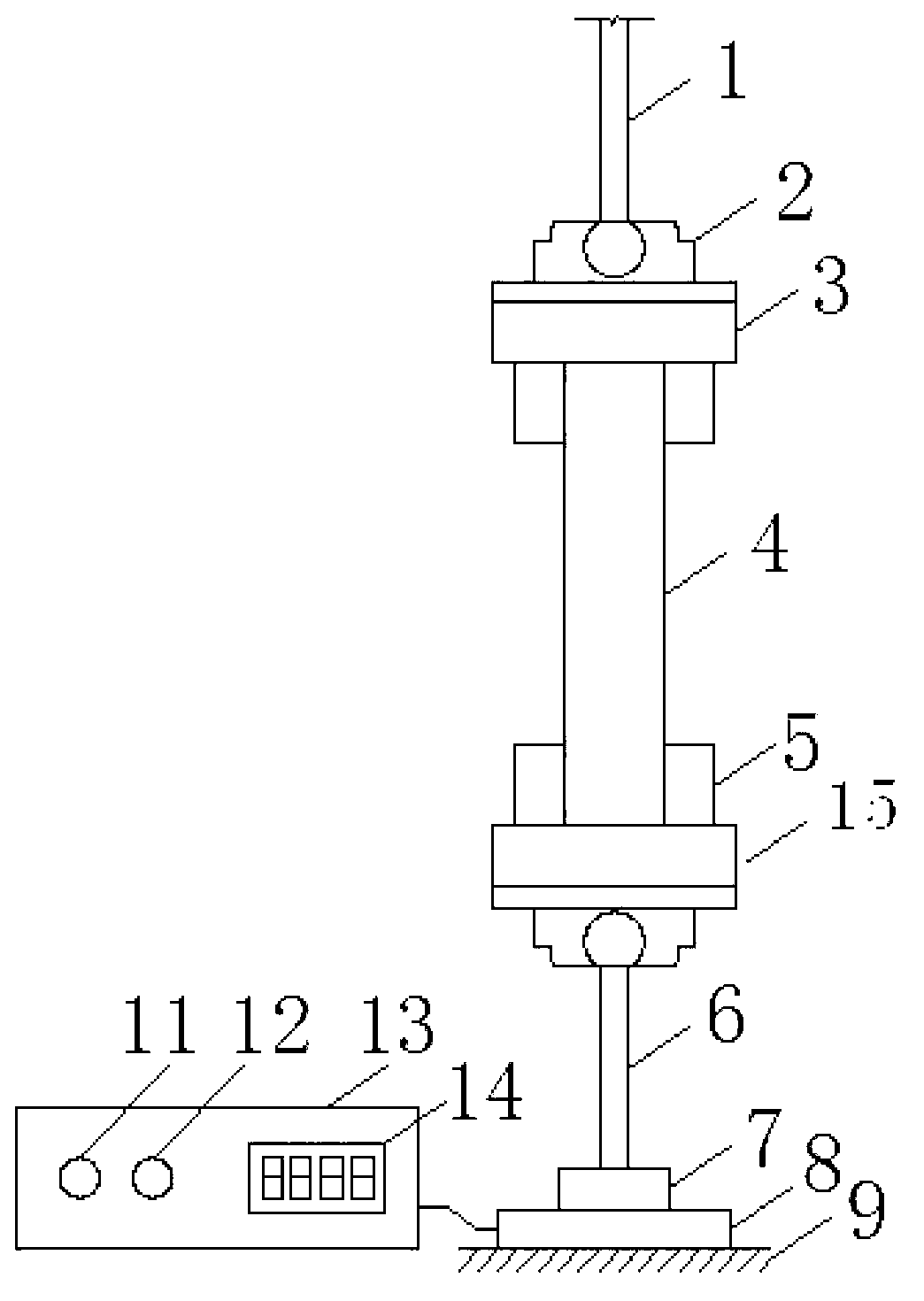

[0023] refer to figure 1 , 2 As shown, the present invention provides a pavement material direct tensile test device that avoids eccentric tension, including a test component, a tested component installed in the test component, and an electromagnetic force control component, wherein, wherein the test component includes a spherical The upper hinged seat 2, and the spherical lower hinged seat 15 matched with the spherical upper hinged seat 2, the spherical upper hinged seat 2 is provided with an upper tie rod 1, and the upper tie rod 1 and the MTS (Mechanical Testing Simulation, mechanical testing and simulation) testing machine connection, the spherical upper hinged seat 2 and the spherical lower hinged seat 15 are equipped with clamps 3 for clamping the tested parts, the tested parts include the trabecular test piece 4, and the cut pavement material trabecular test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com