Tubular pile joint slurry leakage repairing method

A technology of grout leakage and pipe piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve problems such as shedding, unilateral force, and bursting piles, etc., to achieve dense filling of gaps, accelerated resin solidification, and good permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

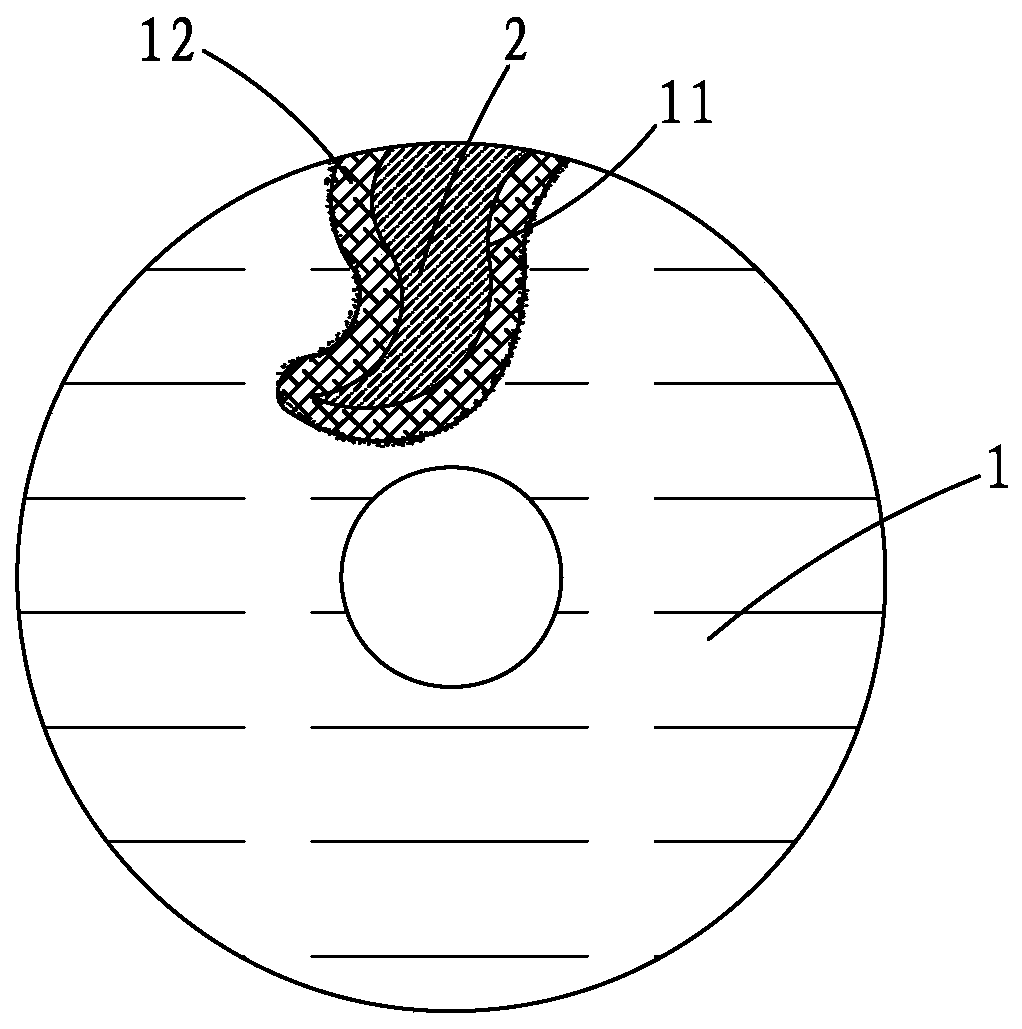

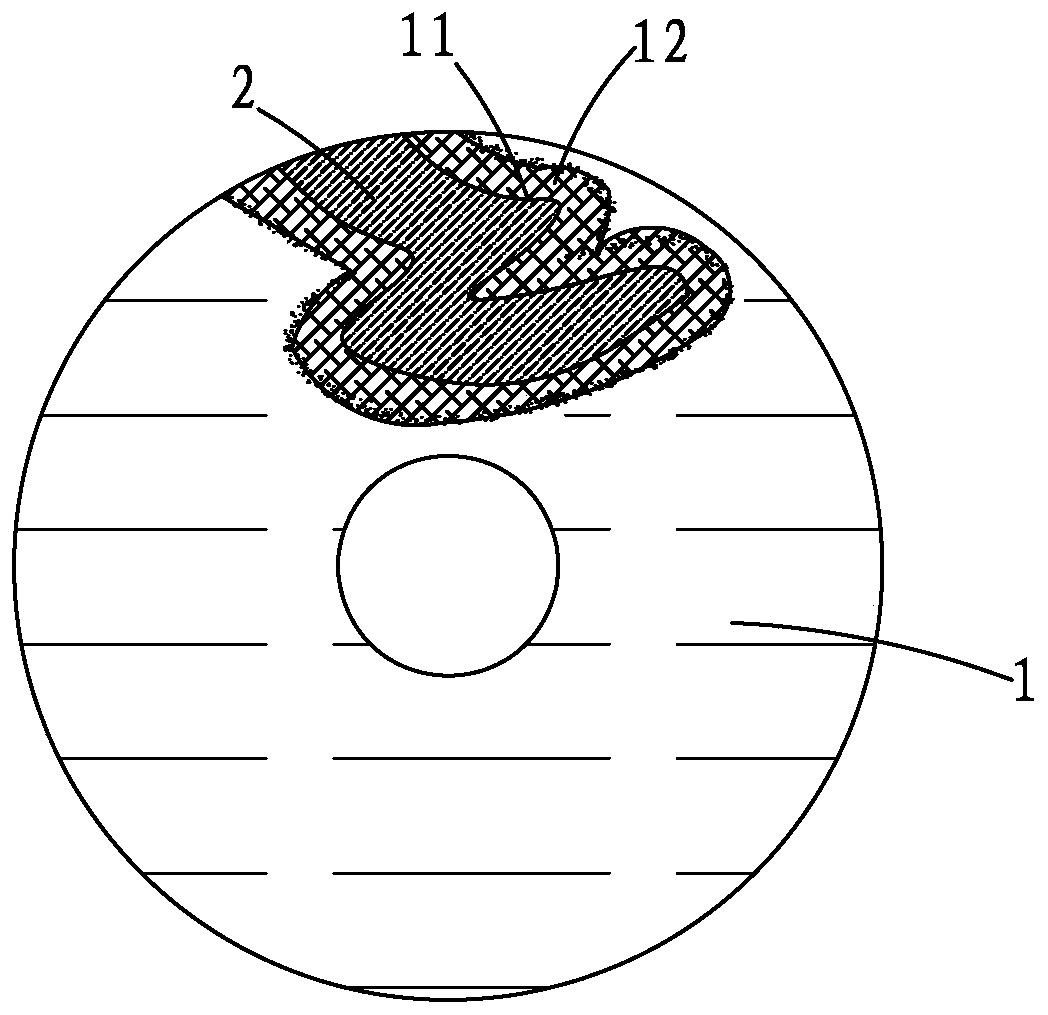

Image

Examples

Embodiment 1

[0023] When using a saturated resin, the saturated resin model is: 3272 saturated polyester resin (oil-free alkyd resin), the main component of the initiator is: anhydrous ethylenediamine, and the ratio of the liquid resin and the initiator is 10:1 Proportion ratio, mortar test mold was used to form the test block, the test time was one day, and the strength was 60.1MPa.

[0024] Repair method:

[0025] Step S1, mixing the liquid resin and the initiator uniformly in a ratio of 10:1 to obtain a repairing agent;

[0026] Step S2. Place the pipe piles with a spreader so that the gaps or holes of the pipe piles face up, so that it is not easy to overflow after adding the repair agent, pour the repair agent into the gaps or holes of the pipe piles, and repeat Several times, stop pouring until the repair agent no longer penetrates into the pipe pile from the gap or hole;

[0027] Step S3, just wait for the repair agent to solidify.

[0028] Step S4. After solidification, if there...

Embodiment 2

[0030] When using unsaturated resin: the type of liquid resin is: Nanbao 111GN, its main components are ethyl acetate, methyl ethyl ketone, PU resin; the initiator is: anhydrous ethylenediamine, and the type of accelerator is: Lubrizol 2063 Accelerator; the ratio of the liquid resin: initiator: accelerator = 10:1:1, using mortar trial mold to form a test block, the test time is one day, and the strength is: 52.3MPa.

[0031] Step S1, mixing the liquid resin, initiator and accelerator uniformly in a ratio of 10:1:1 to obtain a repairing agent;

[0032] Step S2. Place the pipe piles with a spreader so that the gaps or holes of the pipe piles face up, so that it is not easy to overflow after adding the repair agent, pour the repair agent into the gaps or holes of the pipe piles, and repeat Several times, stop pouring until the repair agent no longer penetrates into the pipe pile from the gap or hole;

[0033] Step S3, just wait for the repair agent to solidify.

[0034] Step S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com