Mandrel structure of spiral pusher of horizontal decanter centrifuge

A screw pusher and mandrel structure technology, which is applied to centrifuges, centrifuges with rotating drums, etc., can solve the problem of increasing the operating load and vibration intensity of the centrifuge, eccentric force generated by the screw pusher, and affecting equipment Service life and other issues, to achieve the effect of prolonging the service life of equipment, improving rigidity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0016] The invention provides a novel mandrel structure of a screw pusher.

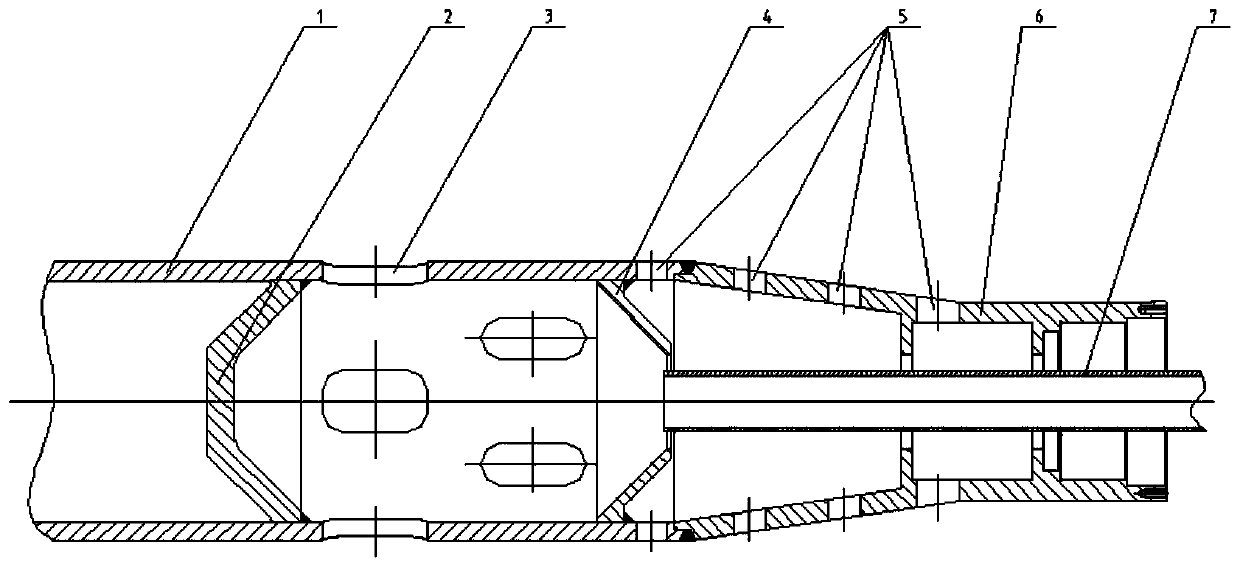

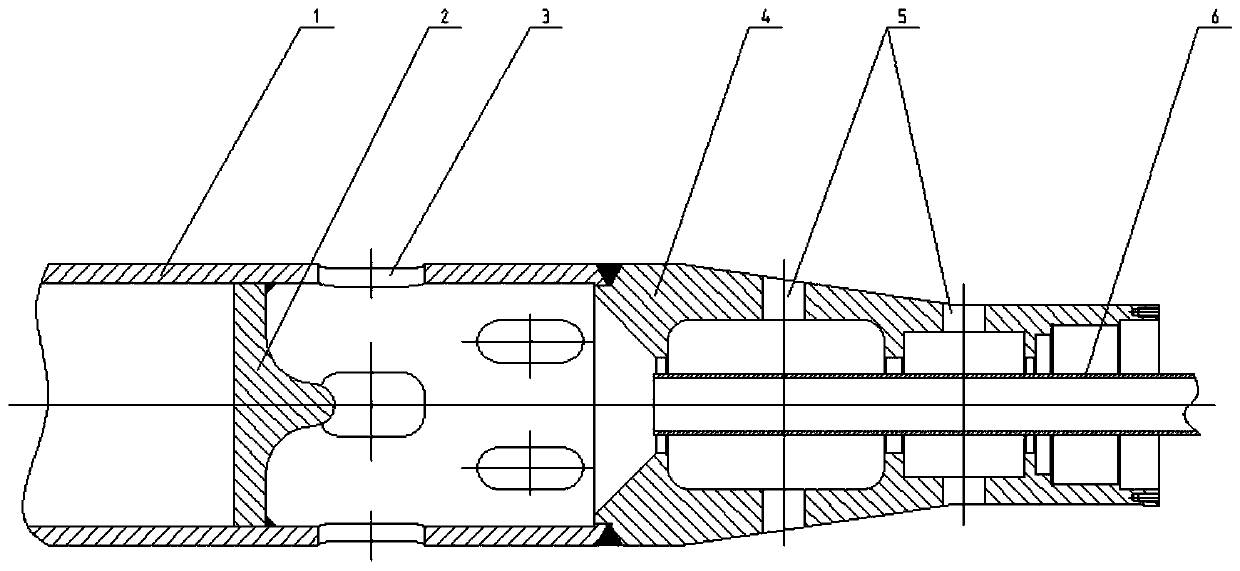

[0017] Such as figure 1 , when the material with a certain flow rate enters the distributing bin from the feed pipe 7, the distributing bin is formed by a combination of a column helix 1, a partition 2, and a cone plate 4, and most of the material enters the inner wall of the drum from the outlet 3 for separation, and a small part Due to the rebound of the partition 2, it will enter the conical helix 6 countercurrently, and most of it will enter the drum from the outlet 5. Since the outlet 5 is only four evenly distributed on the circumference, some materials will still accumulate in the cone after long-term use. In the accumulation space formed by the outside of the plate 4 and the conical helix 6, the screw pusher will generate eccentric force. In addition, due to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com