Double sleeve for pile foundation test and construction technique thereof

A test-use, double-casing technology, which is applied in the test of foundation structure, foundation structure engineering, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

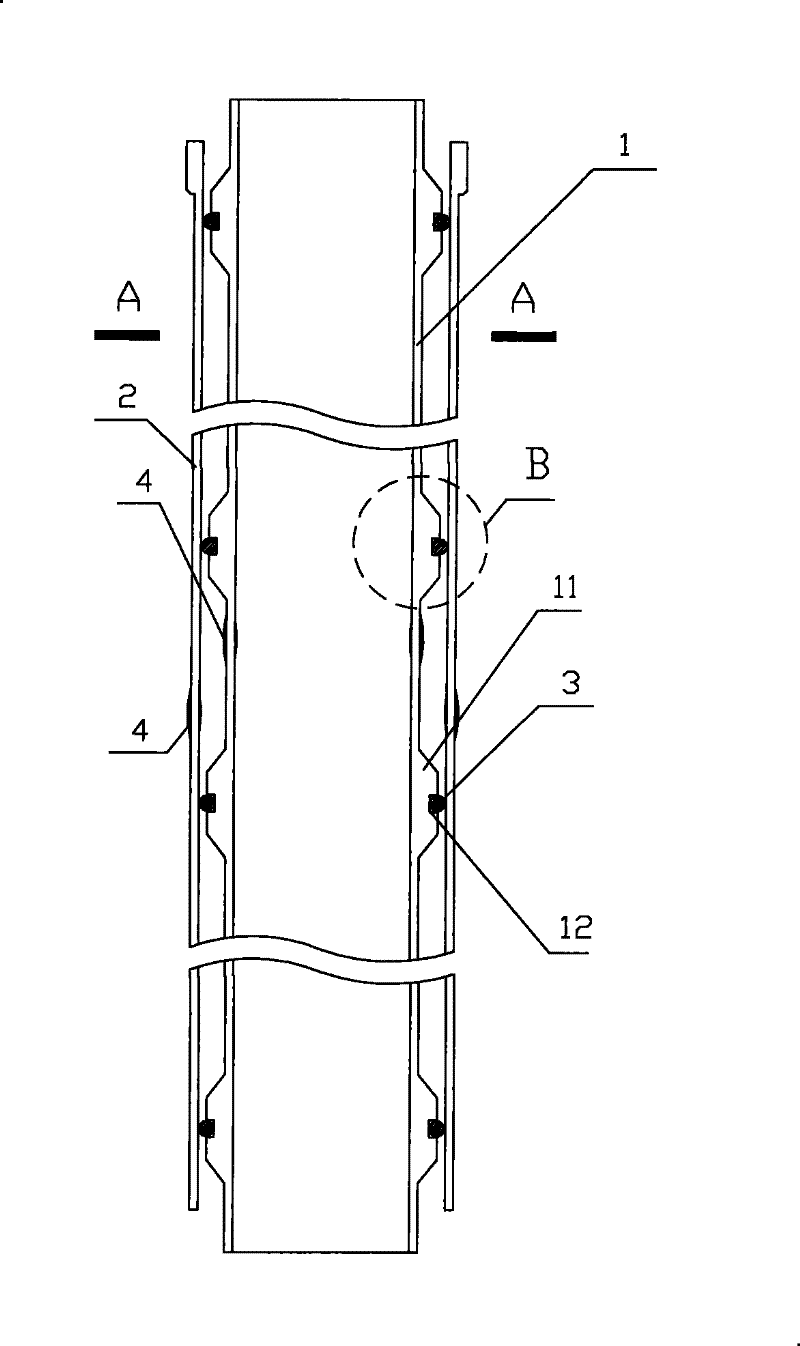

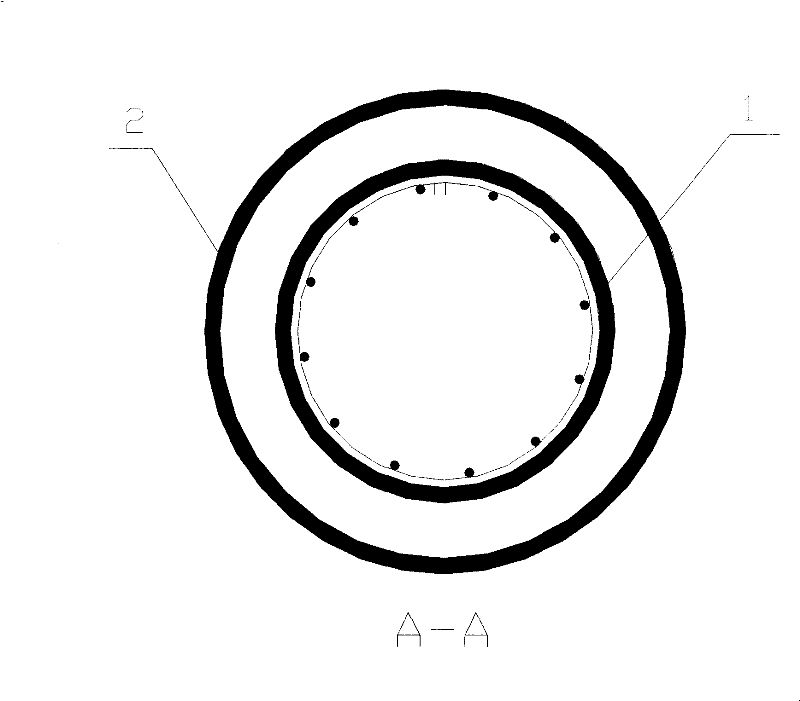

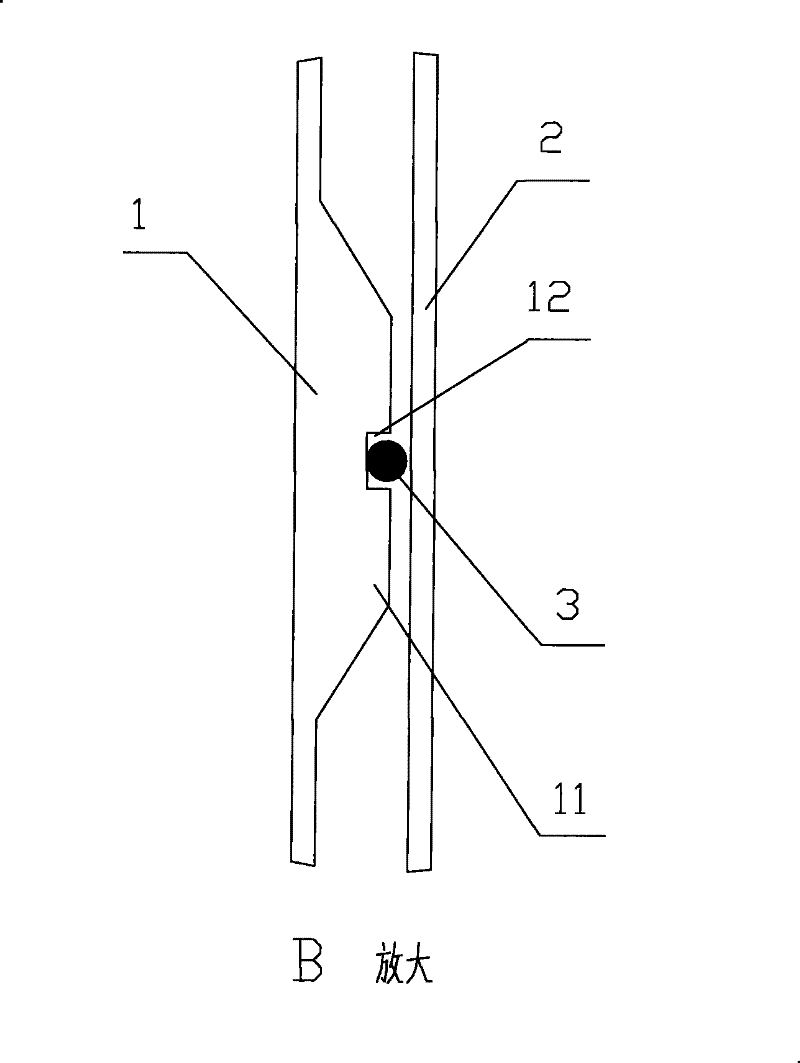

[0031] First please refer to figure 1 and figure 2 Schematic diagram of the structure of the present invention, the illustrated pile foundation test with double sleeves includes an inner sleeve 1 and an outer sleeve 2, the inner sleeve 1 is placed in the lumen of the outer sleeve 2 and is concentric with the outer sleeve 2, the inner sleeve Both the pipe 1 and the outer casing 2 are made of FRP sand-filled pipe, so it has light weight, smooth surface, small friction coefficient, high strength, good hoop and longitudinal rigidity and other excellent mechanical properties, so it can be transported and hoisted conveniently , safe construction operation, and greatly reduce the beneficial effects of lateral frictional resistance between the double casing and the surrounding soil. Due to the limitations of the current glass steel pipe pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com