Device for automatically washing inner of pot

A technology for automatic cleaning and coiling devices, which is applied to spraying devices, spraying devices with movable outlets, and devices for coating liquid on the surface, etc., which can solve the problems of insufficient cleaning of the inner wall of the tank, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred Mode of Carrying Out the Invention

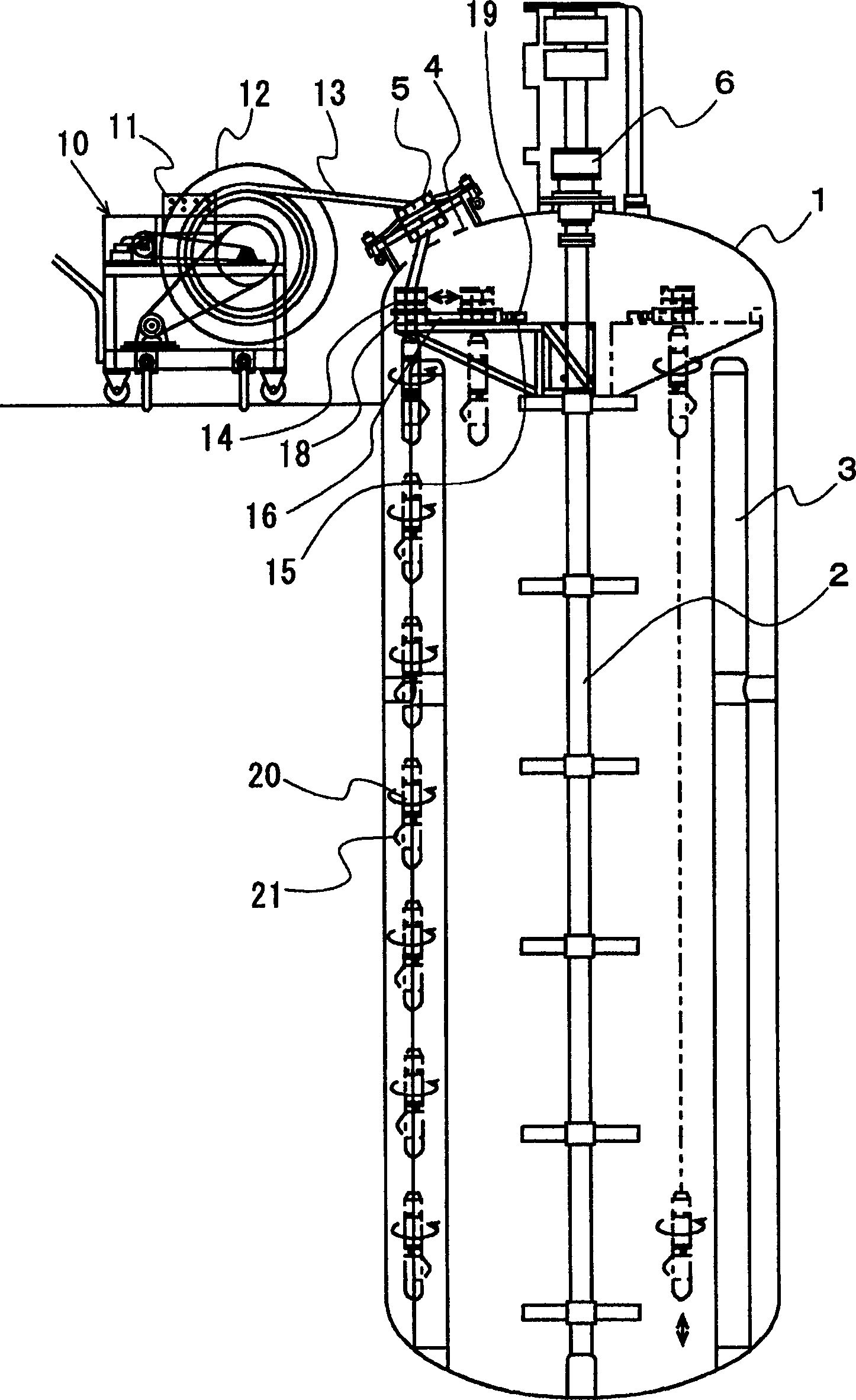

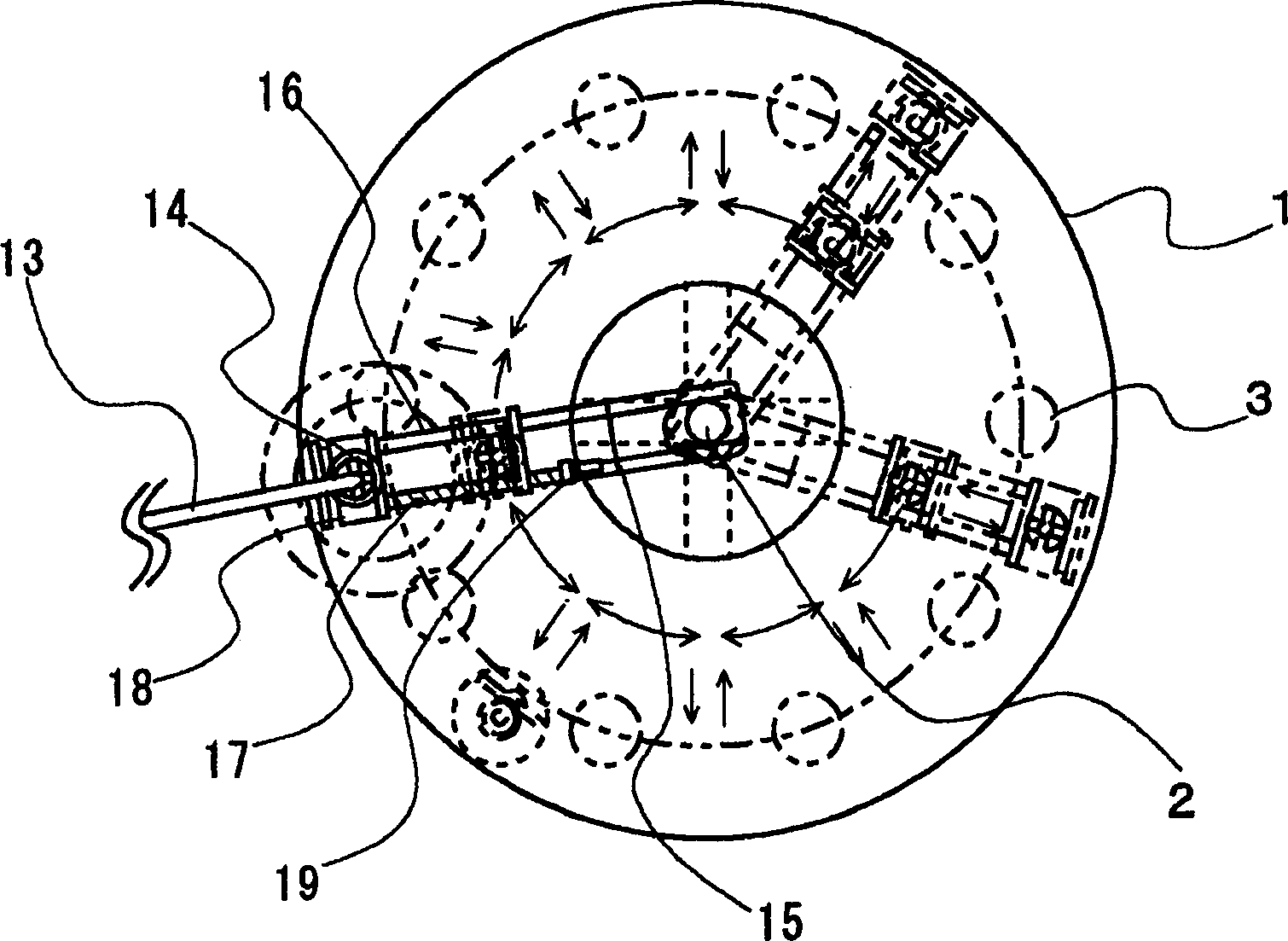

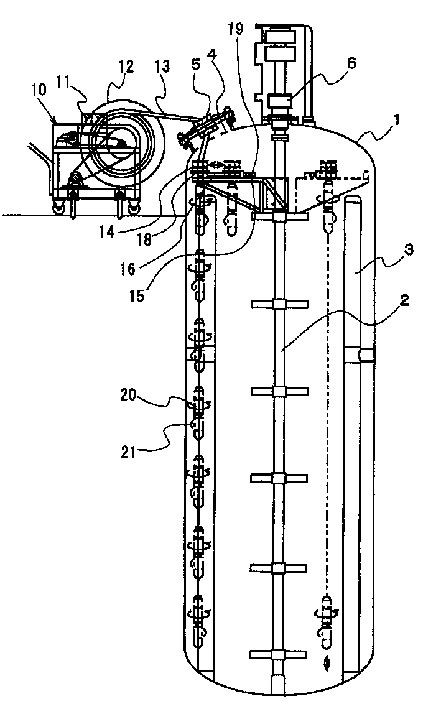

[0021] As shown in these figures, the automatic cleaning device in the tank of this embodiment has the following equipment: the rotating arm 15 that is installed on the top of the impeller shaft 2 on the inner central axis of the tank 1 by utilizing the operation of entering the tank; The inlet 4 above the tank leads to the high-pressure hose 13 that is introduced into the tank 1 of the hose guide 14 that is located on the rotating arm 15; the rotary spray head 20 that is hung on the front end of the high-pressure hose 13; The high-pressure hose 13 is fed into (transported) or drawn out (coiled) from the hose reel 12 and the coiling device 10 of its drive system.

[0022] The rotating arm 15 has a rail mechanism 16 radially extending from the impeller shaft 2 to the tank. By making the hose guide 14 slide back and forth along the rail mechanism 16 in the tank radial direction, the hanging position of the spray head 20 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com