Horizontal baffled alcohol fermentation tank

A technology of alcohol fermentation and clapboard, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. Fermentation efficiency and other issues to achieve the effect of saving equipment investment, improving slip flow and stagnation, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

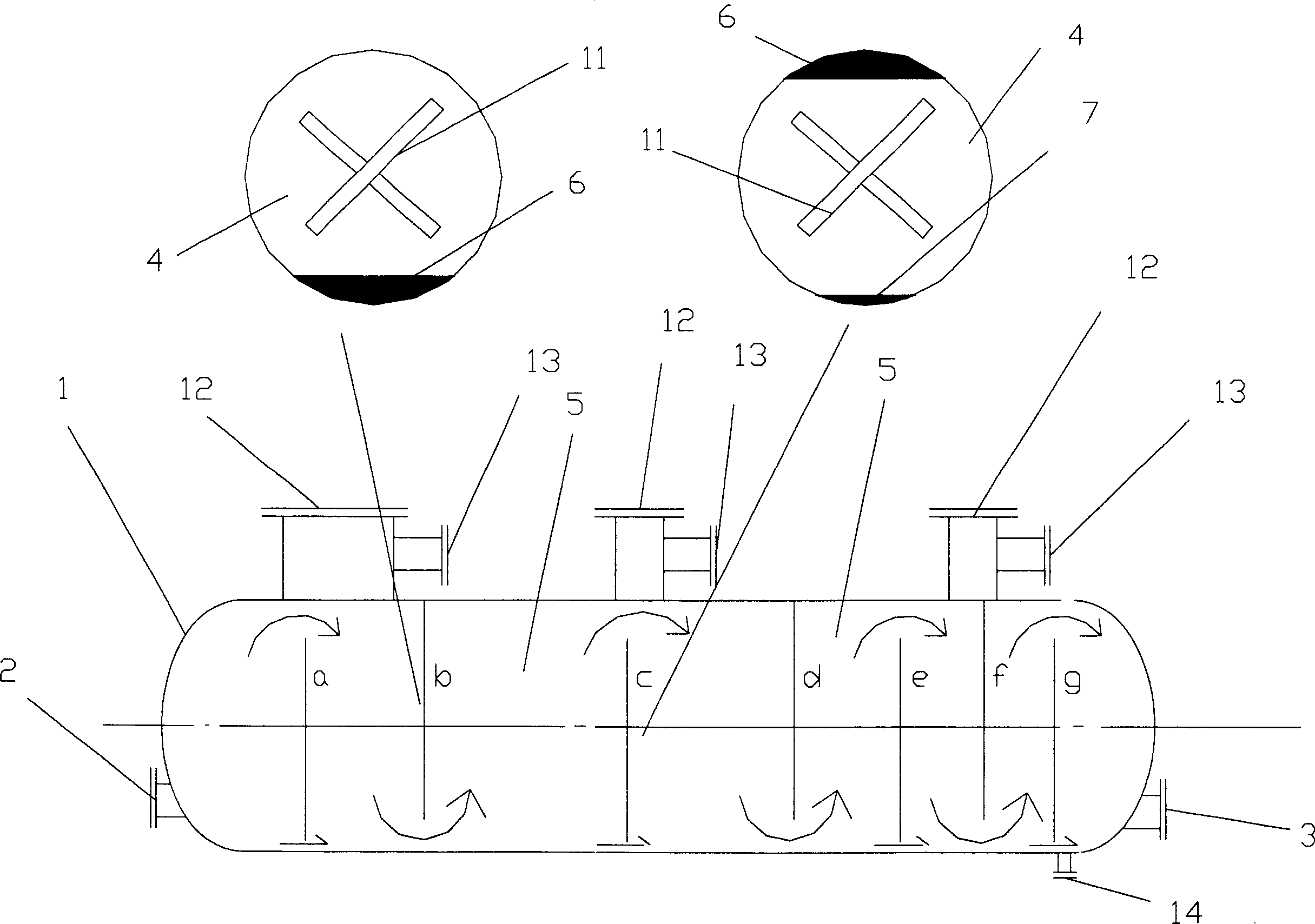

[0025] Embodiment 1: as attached figure 1 As shown, corn is used as raw material, whole-grain dry crushing process is adopted, and the scale of a fermentation workshop with an annual output of 50,000 tons of alcohol is taken as an example: a horizontal clapboard alcohol fermentation tank, the shape of the vertical section of the tank body 1 is circular, and the diameter is φ16000mm , the total length is 26000mm, and its axial ends are respectively provided with material inlet 2 and material outlet 3, and the tank body 1 is vertically arranged with seven partitions 4 in the radial direction, which can divide the tank body into eight intervals 5. The upper or lower part of the plate 4 is provided with gaps 6 communicating with the intervals 5 on both sides of the partition 1, the gaps 6 on two adjacent partitions 4 are staggered up and down, and the intervals 5 in the tank body 1 communicate through each gap in turn, which is equivalent to Eight fermenters connected in series of...

Embodiment 2

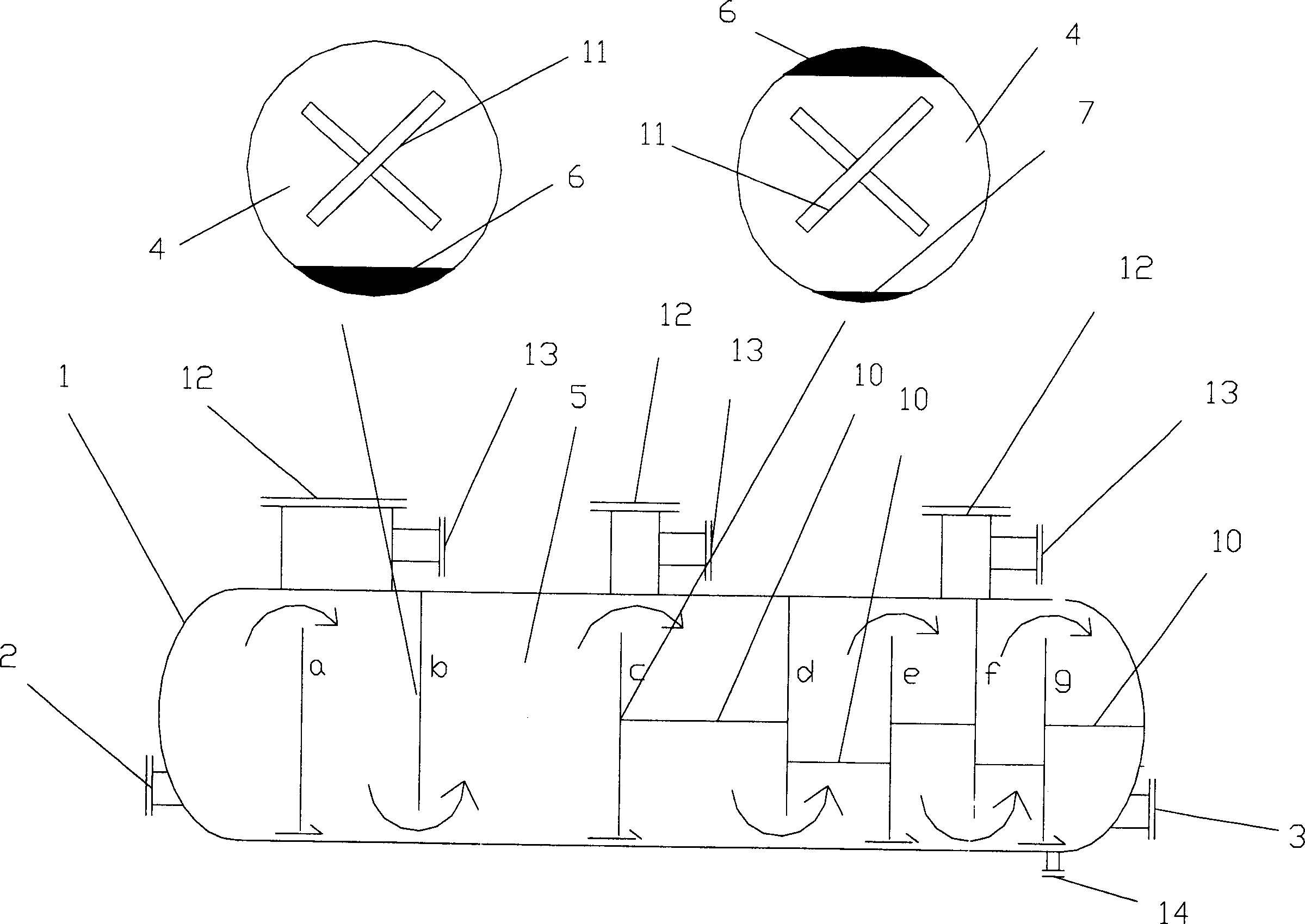

[0042] Embodiment 2: as attached figure 2As shown, taking cornstarch milk as raw material and a fermentation workshop with an annual output of 100,000 tons of alcohol as an example, the horizontal clapboard alcohol fermentation tank, the vertical cross-section of the tank body 1 is circular, the diameter is φ16000mm, and the total length is 52000mm , its axial ends are respectively provided with a material inlet 2 and a material outlet 3, and seven partitions 4 are arranged vertically in the radial direction of the tank body 1, which can divide the tank body into eight intervals 5. The gaps 6 that communicate with the gaps 5 on both sides of the partition 1, the gaps 6 on the two adjacent partitions 4 are staggered up and down, and the gaps 5 in the tank body 1 are connected sequentially through the gaps, which is equivalent to eight in the prior art. Fermentation tanks connected in series.

[0043] The lower part of the partition 4 with the notch 6 on the upper part is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com