Seaweed amino acid salt and preparation method thereof

A technology of amino acid salt and seaweed, which is applied in the field of food condiments, can solve the problems of low utilization of beneficial ingredients, and achieve the effects of improving cell viability, increasing vibration amplitude, and increasing mass transfer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

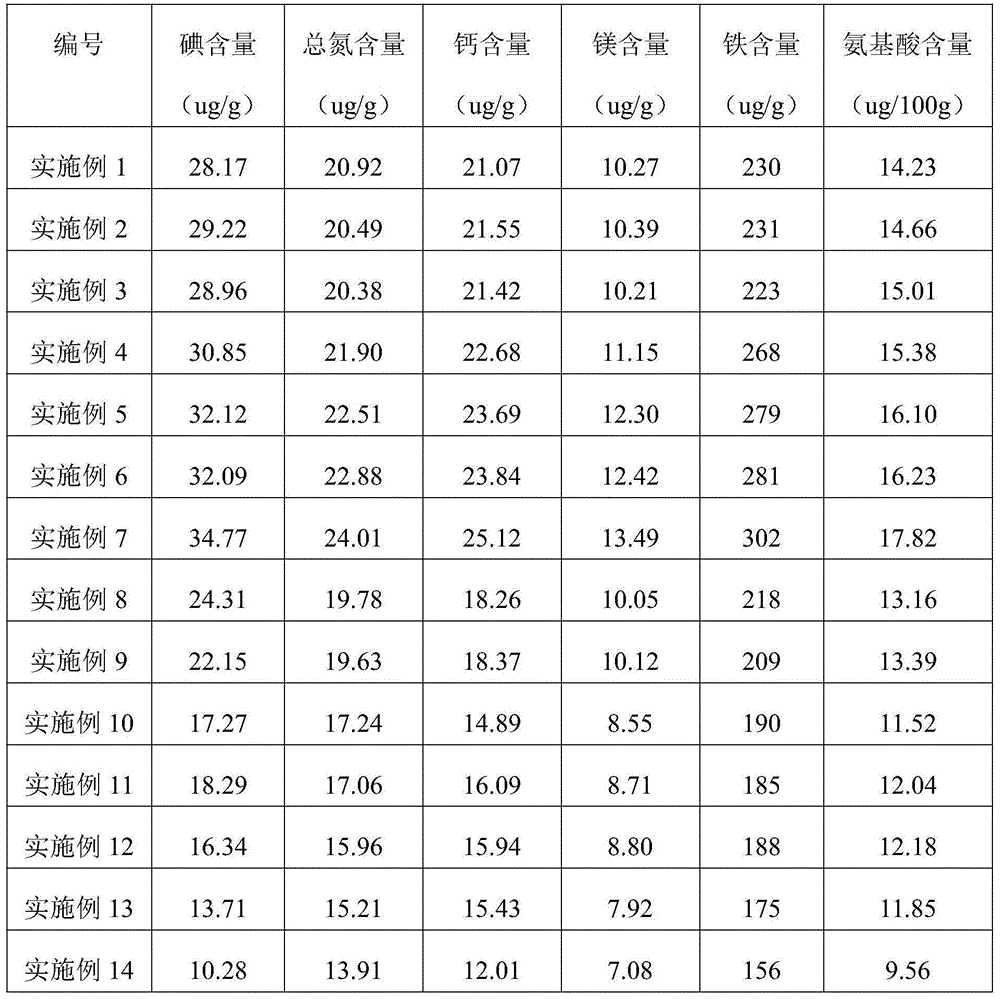

Examples

Embodiment 1

[0028] The seaweed amino acid salt described in this embodiment is prepared according to the following method:

[0029] (1) Prepare the required refined table salt (99% sodium chloride content, without iodine) according to conventional methods, and set aside;

[0030] (2) After the kelp is sterilized, disinfected, and soaked, it is heated at 25-30kHz, 200mW / cm 2 Sinusoidal ultrasonic and 30-35kHz, 200mW / cm 2 Under the condition of co-oscillating with variable-frequency ultrasonic waves, pulping for 4 hours to obtain seaweed slurry, and through quick freezing, concentration, spray drying, and crushing, the seaweed extract was obtained and set aside;

[0031] (3) Take 10 kg of the refined table salt prepared in step (1), and mix the seaweed extract prepared in the step (2) which accounts for 15 wt % of the refined table salt weight;

[0032] (4) The seaweed amino acid salt is prepared by a conventional method for preparing edible refined salt.

Embodiment 2

[0034] The seaweed amino acid salt described in this embodiment is prepared according to the following method:

[0035] (1) prepare required refined table salt (with embodiment 1) according to conventional method, for subsequent use;

[0036] (2) After the kelp is sterilized, disinfected, and soaked, it is heated at 30kHz, 200mW / cm 2 Sinusoidal ultrasonic and 35kHz, 200mW / cm 2 Under the condition of co-oscillating with variable-frequency ultrasonic waves, pulping for 4 hours to obtain seaweed slurry, and through quick freezing, concentration, spray drying, and crushing, the seaweed extract was obtained and set aside;

[0037] (3) Take 10 kg of the refined table salt prepared in step (1), and mix the seaweed extract prepared in the step (2) which accounts for 25 wt % of the refined table salt weight;

[0038] (4) Adopt the method (with embodiment 1) of routine preparation edible refined salt to make described seaweed amino acid salt.

Embodiment 3

[0040] The seaweed amino acid salt described in this embodiment is prepared according to the following method:

[0041] (1) Prepare the required refined table salt (same as Example 1) according to conventional methods, and set aside;

[0042] (2) After the kelp is sterilized, disinfected, and soaked, it is heated at 25kHz, 200mW / cm 2 Sinusoidal ultrasonic and 40kHz, 200mW / cm 2 Under the condition of co-oscillating with variable-frequency ultrasonic waves, pulping for 4 hours to obtain seaweed slurry, and through quick freezing, concentration, spray drying, and crushing, the seaweed extract was obtained and set aside;

[0043](3) Take 10 kg of the refined table salt prepared in step (1), and mix the seaweed extract prepared in the step (2) which accounts for 15 wt % of the refined table salt weight;

[0044] (4) Adopt the method (with embodiment 1) of routine preparation edible refined salt to make described seaweed amino acid salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com