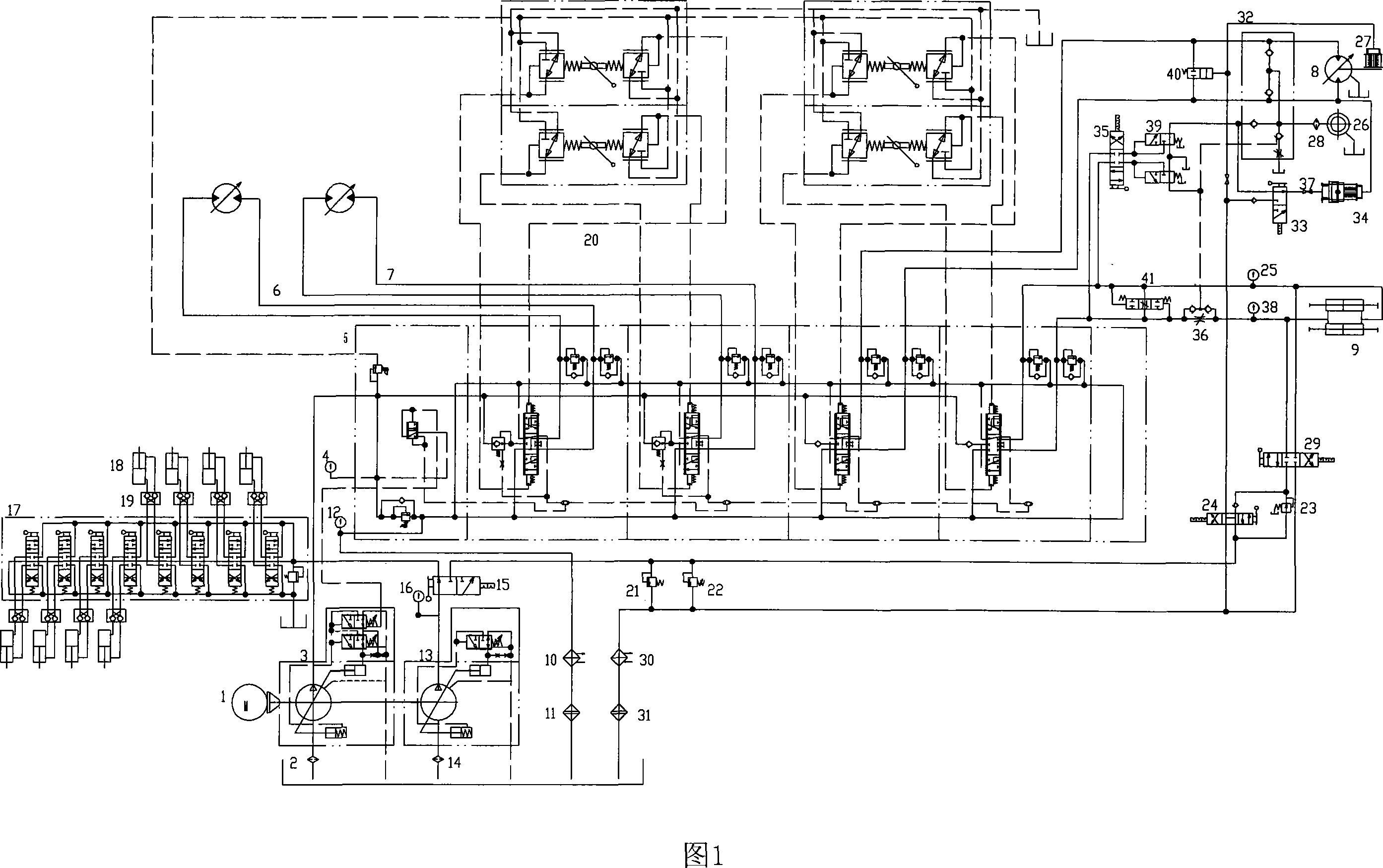

Caterpillar belt self-walking type tunnel drilling rig hydraulic system

A hydraulic system and tunnel drilling rig technology, applied in the field of drilling machinery, can solve the problems of control lag, low hydraulic system efficiency, and low control accuracy, and achieve the effects of fast response, convenient control, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention selects a load sensitive pump with advanced performance and a constant pressure variable pump to form the power device of the system, and applies the hydraulic control reversing valve and remote control technology, and uses the connection relationship between various valves to form a linkage action, so as to Adapt to different drilling operations.

[0024] The present invention adopts a load sensitive pump 3 and a multi-way reversing valve 5 with a load feedback function. Among them, the first two joints equipped with differential pressure reducing valves are used to control the travel motors 6 and 7, so as to realize functions such as straight-line travel, turning, and U-turn of the drilling rig. The third link is used to control the power head power head motor 26, and the fourth link controls the rapid movement of the feeding oil cylinder. Wherein the load sensing valve is controlled by a remote control valve 20 .

[0025] This system also adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com