Full automatic brazing machine for radiator

A radiator, fully automatic technology, applied in electric heating devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, difficulty in ensuring the welding quality of copper-aluminum composite radiators, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

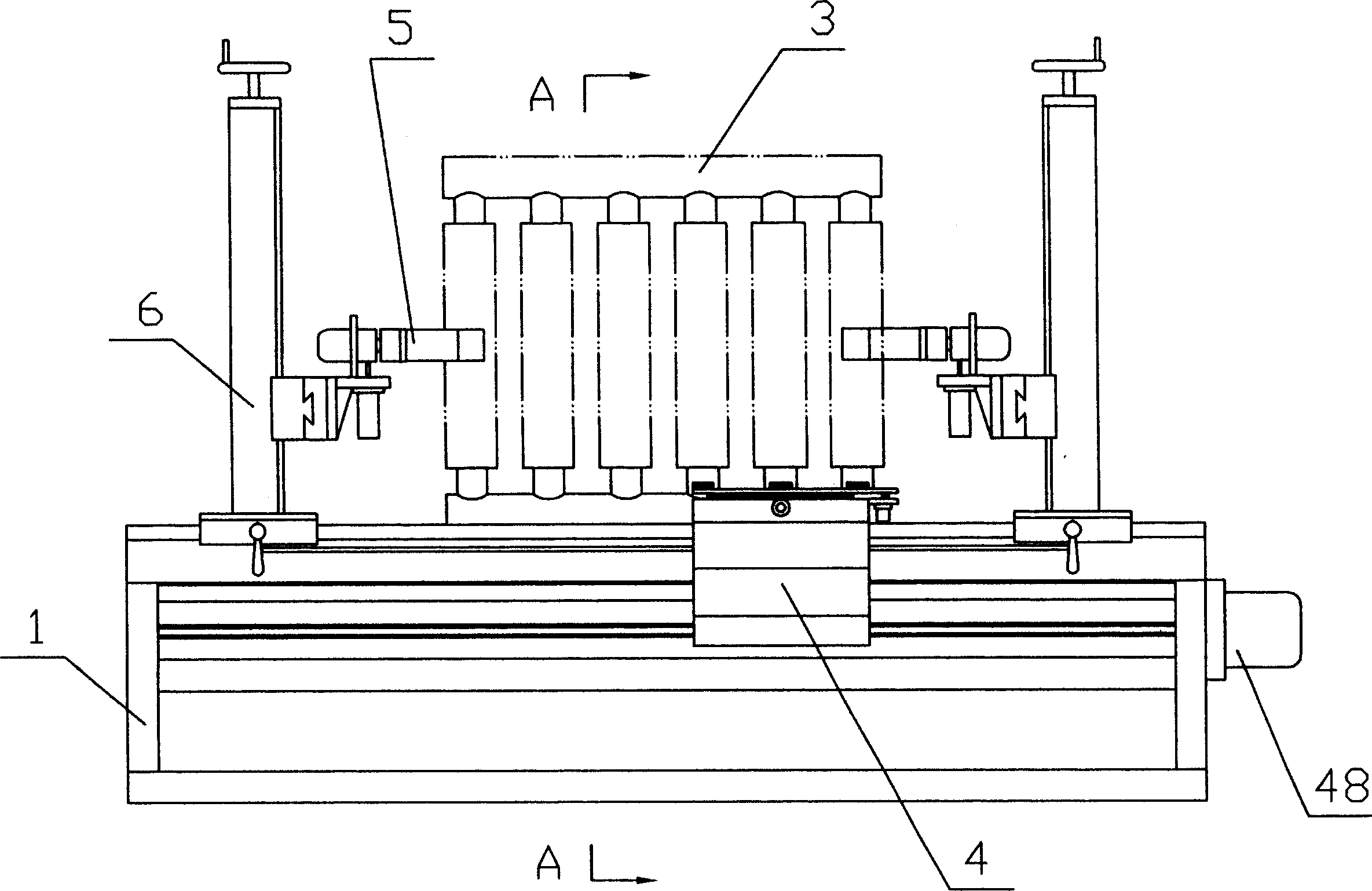

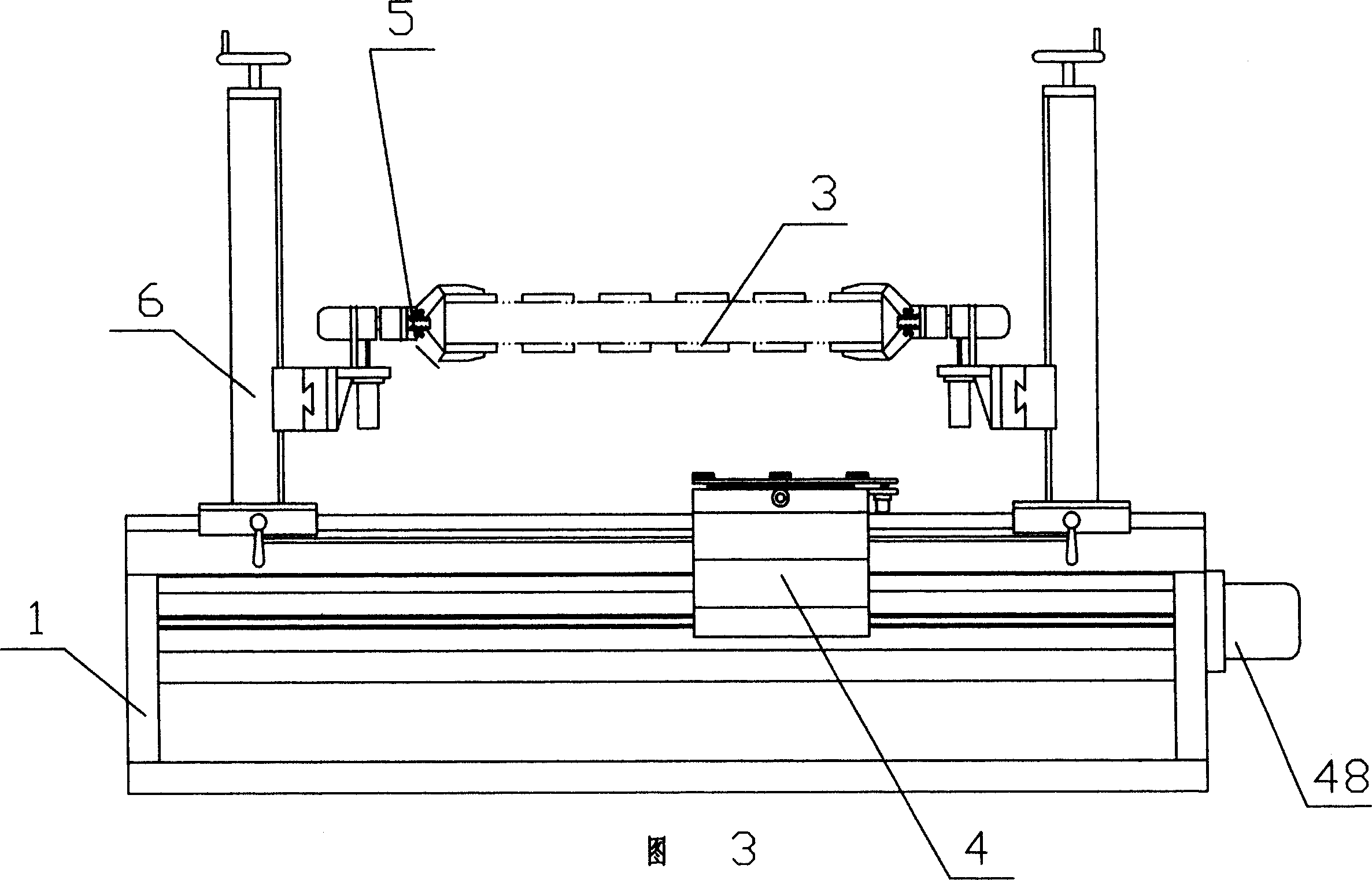

[0025] Example one: such as figure 1 , figure 2 3. As shown in Figure 3, the radiator automatic brazing machine includes a frame 1, a radiator positioning device 2 installed on the frame 1, and a welding device 4 symmetrically arranged on both sides of the radiator 3, installed on the frame 1. The supporting arm 6 of the clamping device, the radiator clamping device 5 installed on the supporting arm 6 of the clamping device, the clamping device 5 includes a clamping head 51, and a turning power device 52 that drives the clamping head 51 to turn over , The lifting power device 53 that can drive the clamping head 51, the radiator 3, and the turning power device 52 up and down. The lifting power device 53 is installed on the clamping device frame 54 and the clamping device frame 54 and The support arm 6 of the clamping device is connected.

[0026] Such as Figure 7 As shown, the clamping head 51 includes a symmetrical clamping arm 51a, a cylinder 51b that controls the opening and ...

Embodiment 2

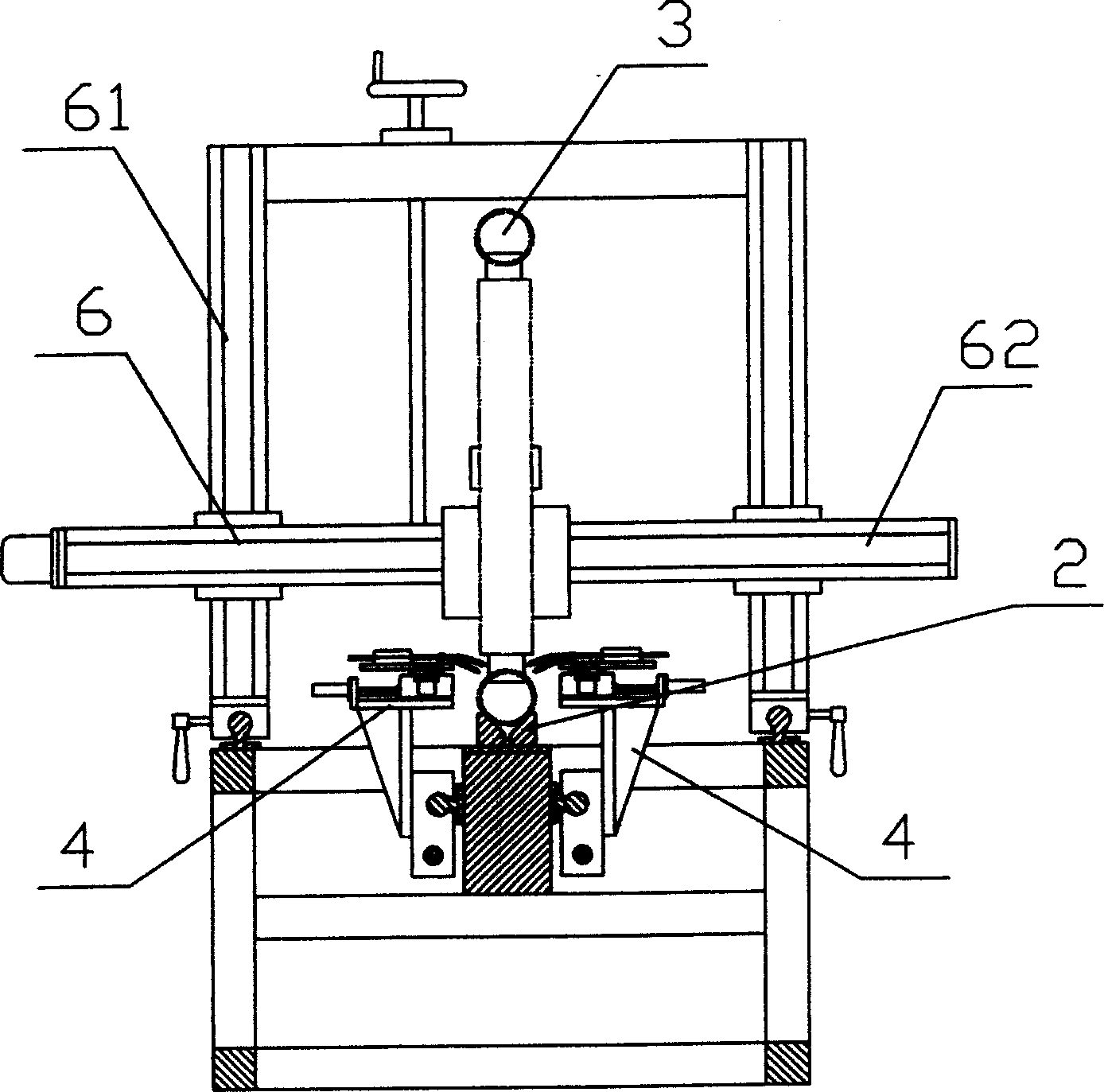

[0039] Embodiment two: such as Figure 8 As shown, the difference between this embodiment and the first embodiment is that the clamping device support arm 6 includes vertical arms 61 arranged on the frame 1 and located at both ends of the radiator 3, and the clamping device 5 The position on the stand arm 61 can be adjusted up and down. That is to say, the support arm 6 of the clamping device has only a vertical arm 61, but no cross arm. The placing of the workpiece, the welding of the workpiece, and the removal of the workpiece are all completed at the positioning device.

[0040] The working process of this embodiment is as follows:

[0041] The first step: the clamping device 5 is located above the positioning device, the clamping device 5 is opened under the action of power, the workpiece is placed and positioned, and the clamping device 5 clamps the workpiece;

[0042] Step 2: After the workpiece is positioned and clamped, the feed table 43 drives the welding torch frame 42 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com