Electric blowing fan and electric vacuum cleaner equipped therewith

A blower, motor technology, applied in the direction of vacuum cleaners, mechanical equipment, machines/engines, etc., can solve the problems of inability to maintain the fan cover in the specified position, difficult to obtain the outer dimensional accuracy, damage to the diffuser or tailstock, etc., to achieve reliable diameter. Directional positioning, increased contact area, and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

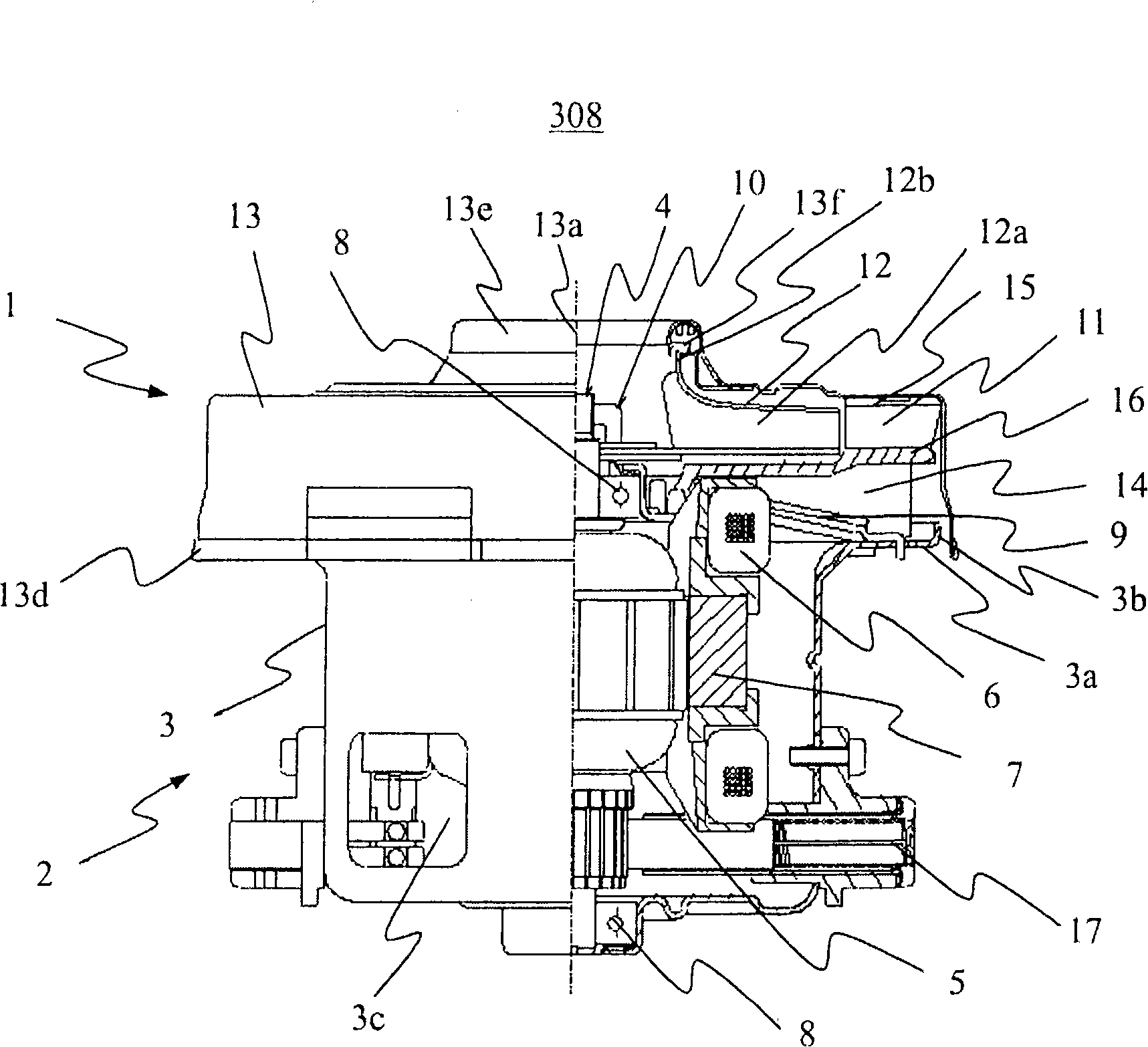

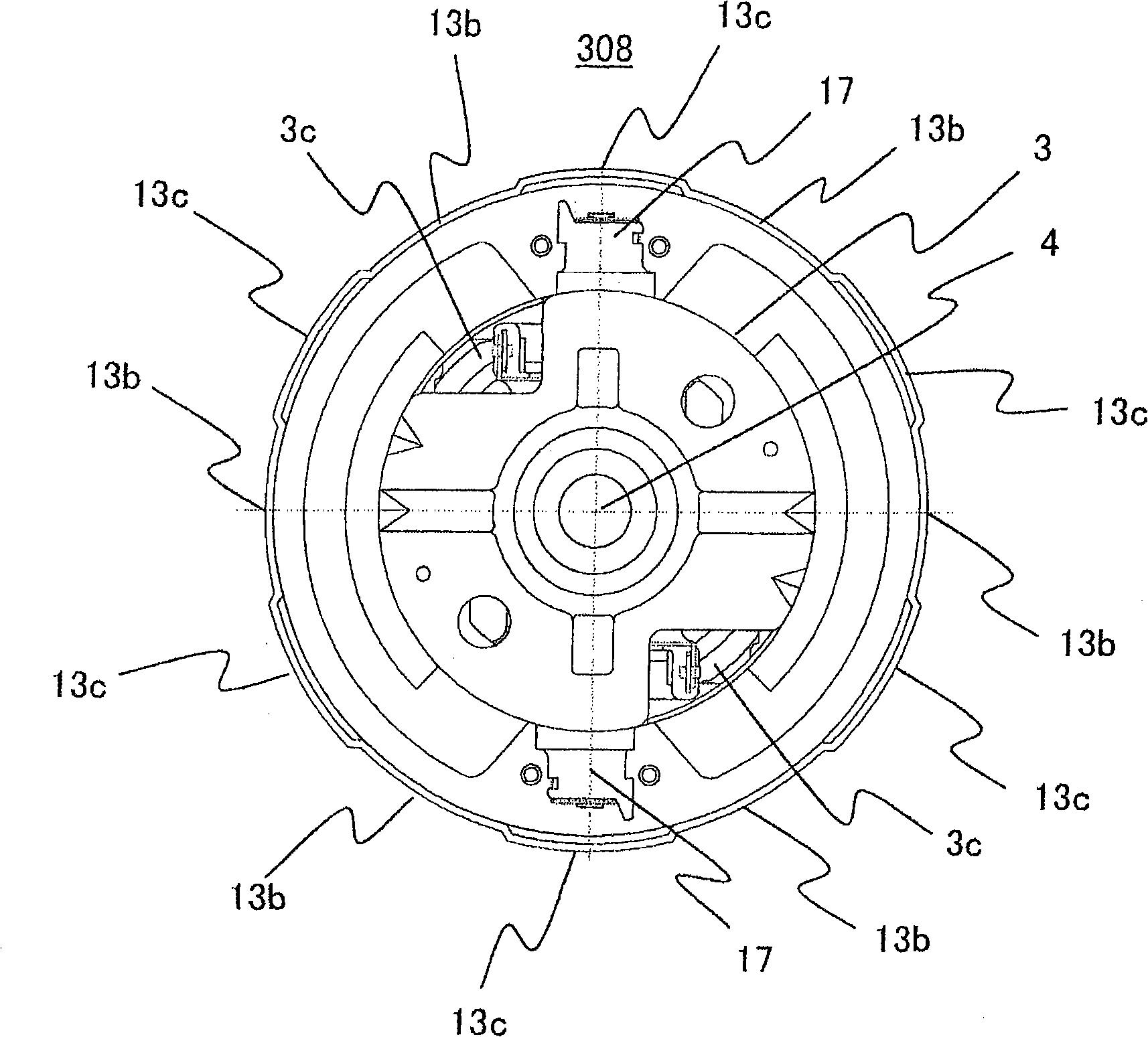

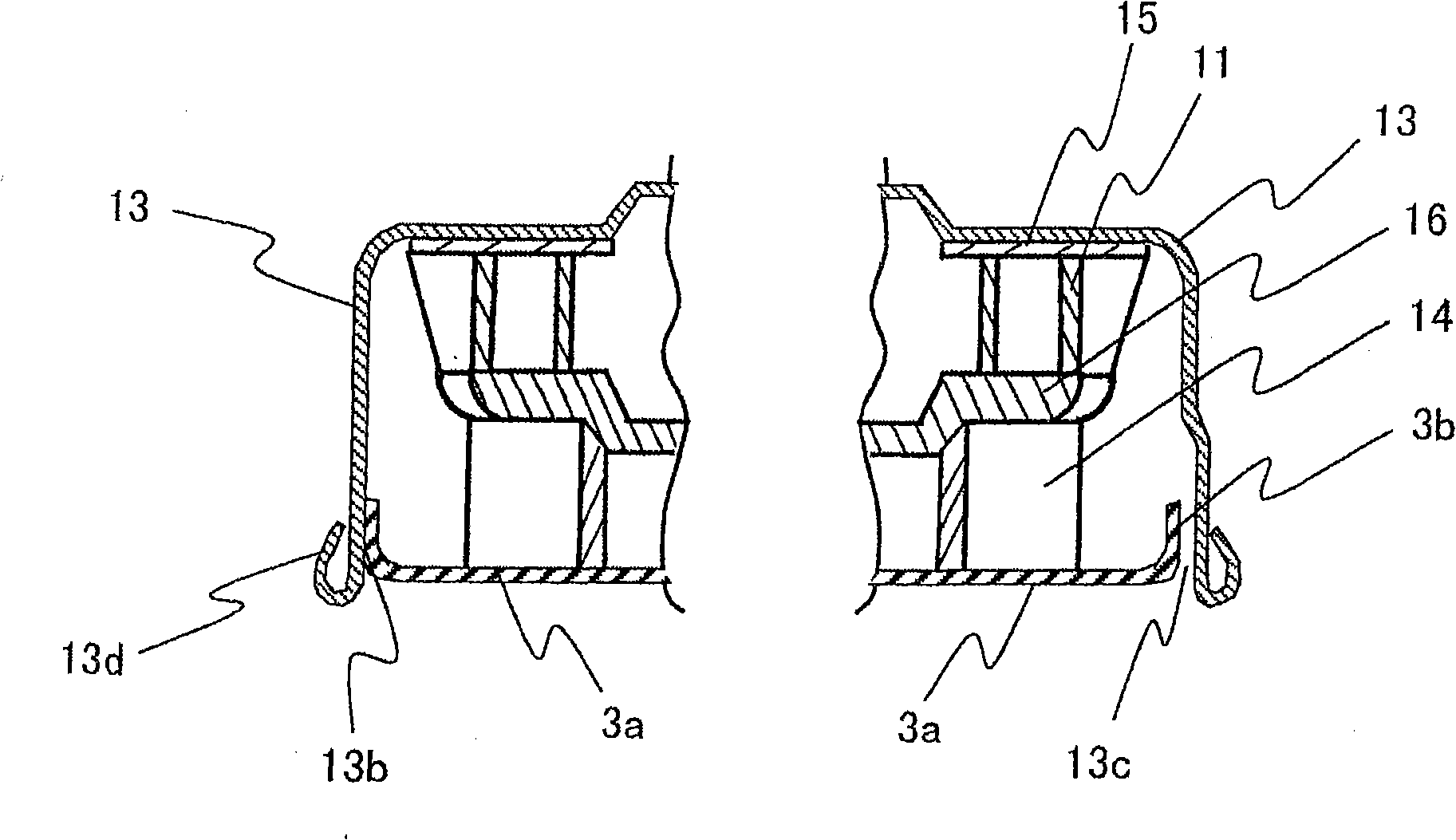

[0030] Embodiments of the present invention will be described below with reference to the drawings.

[0031] according to Figure 6 as well as Figure 7 An electric vacuum cleaner according to an embodiment of the present invention will be described. Figure 6 A perspective view showing the appearance of the electric vacuum cleaner of this embodiment.

[0032] Symbol 201 is to accommodate the dust collecting chamber for collecting dust and the electric blower 308 ( Figure 7 ), the symbol 202 is a hose connected to the vacuum cleaner body 201 at one end, the symbol 203 is the handle operation part connected to the other end of the hose 202, and the symbol 204 is an extension connected to the other end of the handle operation part 203 The pipe, symbol 205 is a suction body connected to the other end of the extension pipe 204 . Reference numeral 206 denotes a switch portion provided on the handle operating portion 203 for turning on and off the electric blower 308 .

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com