Drill-rod fixed clamp and control method thereof

A technology of drill pipe and dead sticking, which is applied in the direction of earthwork drilling, wellbore/well components, sealing/isolation, etc., which can solve problems such as troublesome installation and disassembly, operation failure, and heavy weight, so as to increase safety and stability performance, increased stability and safety, easy and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

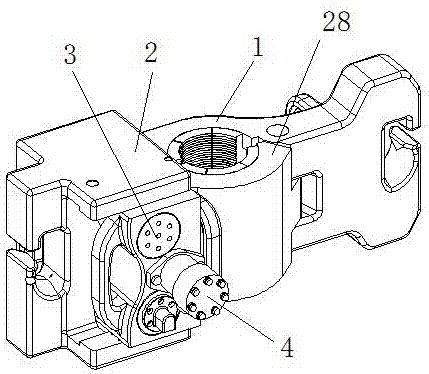

[0069] As a preferred embodiment of the present invention, with reference to the attached figure 1 To attach Figure 7 , this embodiment discloses a drill pipe stuck and its control method, this embodiment includes:

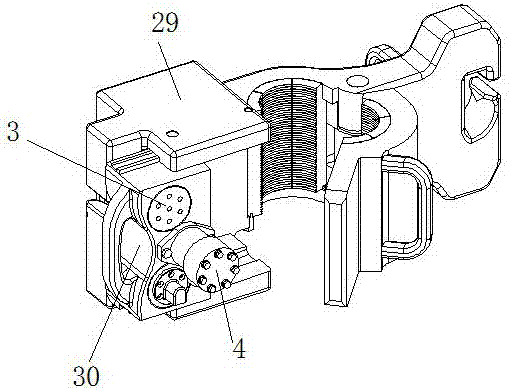

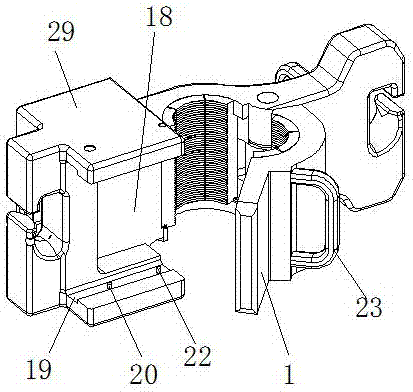

[0070] A drill pipe deadlock, including deadlock assembly I1 and deadlock assembly II28, one end of deadlock assembly I1 and deadlock assembly II28 is hinged together; one end of deadlock assembly I1 is fixedly connected to locking device 2, and the other end is connected to deadlock The assembly II28 is hinged; one end of the deadlock assembly II28 is hinged with the deadlock assembly I1, and the other end is a movable end; the locking device 2 includes a locking device body 29 and a sliding part 30 that can slide along the locking device body 29, A groove 18 is provided between the sliding part 30 and the locking device body 29 for placing the movable end of the dead card assembly II 28 .

[0071] The locking device body 29 is provided with a C-shaped groove ...

Embodiment 2

[0115] As a preferred embodiment of the present invention, with reference to the attached figure 1 to attach Figure 7 , this embodiment discloses a drill pipe deadlock, this embodiment includes:

[0116] A drill pipe deadlock, including deadlock assembly I1 and deadlock assembly II28, one end of deadlock assembly I1 and deadlock assembly II28 is hinged together; one end of deadlock assembly I1 is fixedly connected to locking device 2, and the other end is connected to deadlock The assembly II28 is hinged; one end of the deadlock assembly II28 is hinged with the deadlock assembly I1, and the other end is a movable end; the locking device 2 includes a locking device body 29 and a sliding part 30 that can slide along the locking device body 29, A groove 18 is provided between the sliding part 30 and the locking device body 29 for placing the movable end of the dead card assembly II 28 .

Embodiment 3

[0118] As a preferred embodiment of the present invention, with reference to the attached figure 1 to attach Figure 7 , this embodiment discloses a drill pipe deadlock, this embodiment is basically the same as Embodiment 2, the difference is:

[0119] The locking device body 29 is provided with a C-shaped groove corresponding to the size of the sliding part 30, and the sliding part 30 is arranged in the C-shaped groove; the side walls of the upper and lower ends of the C-shaped groove are provided with slide grooves 19 , a slider 25 corresponding to the sliding groove 19 is provided at a position corresponding to the sliding part 30 , and the slider 25 is arranged in the sliding groove 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com