Preparation method for modified LiFePO4 lithium ion battery anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting large-scale industrial production, difficult to control the purity of products, and difficult to mix uniform raw materials, etc., to achieve good electrochemical performance, Good toughness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

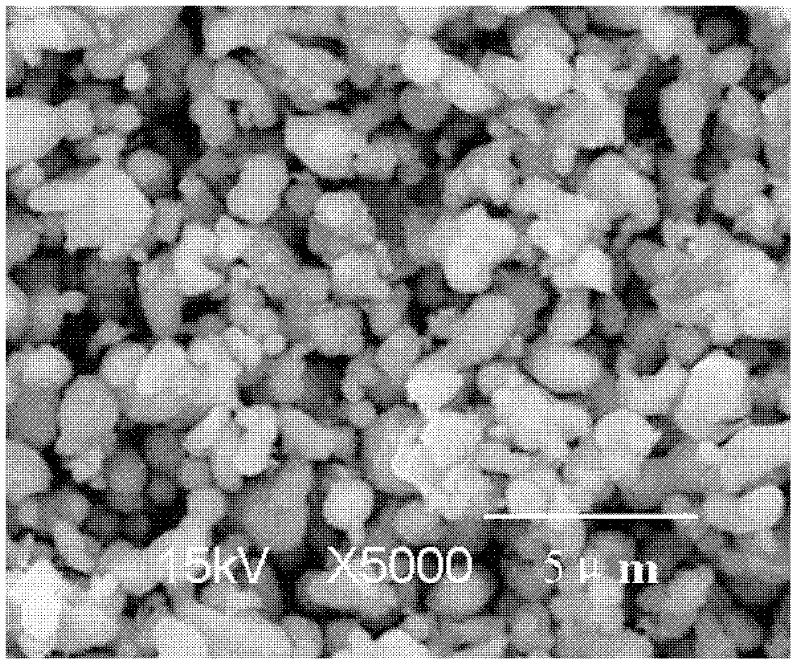

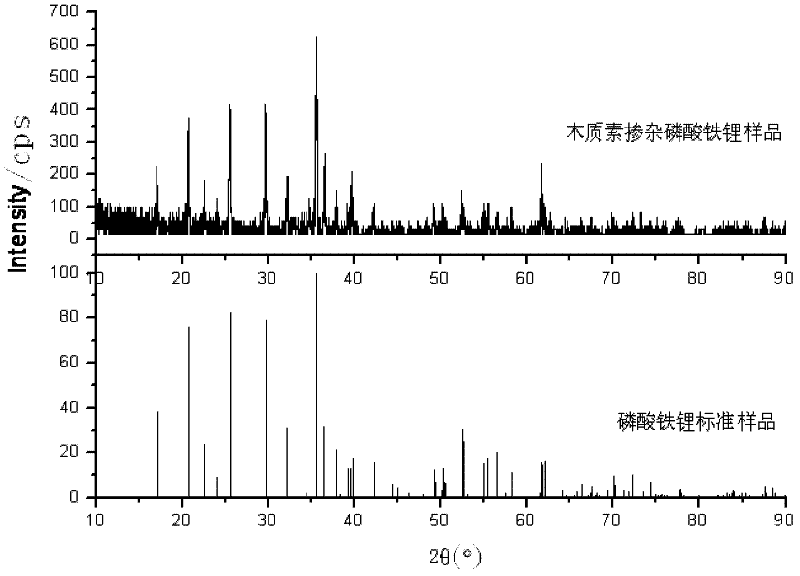

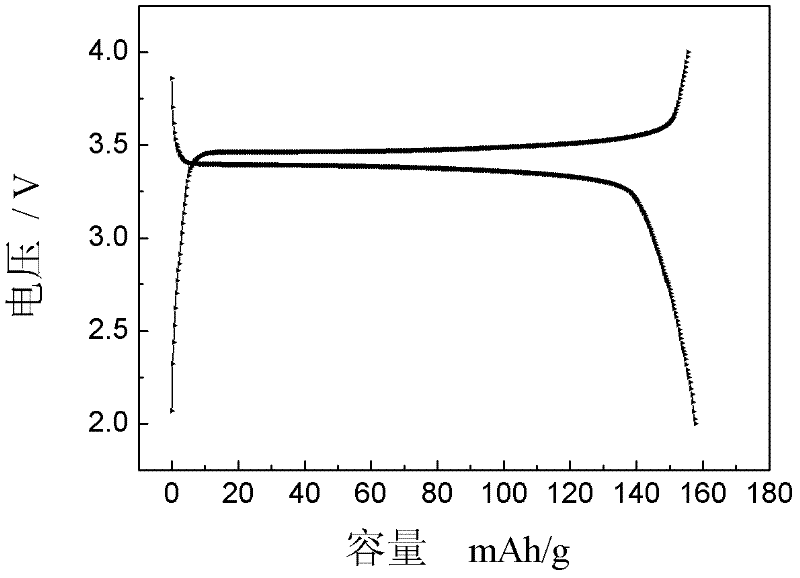

[0037] Add 73.82 grams of ethanol solvent in the double-helix mixing mixer, while stirring, add 40.63 grams of lithium carbonate, 179.89 grams of ferrous oxalate, 115.03 grams of ammonium dihydrogen phosphate and 33.55 grams of ammonium lignosulfonate, and continue to stir for 7 hours until fully reacted, Mix evenly to generate Fe-containing 2+ 、PO 4 3- , Li + The liquid phase colloid mixture, and then vacuum-dried at 60°C; the dried material was put into a ball mill container filled with hydrogen or nitrogen atmosphere and ball milled for 5 hours, and the ball milled material was pressed into a disc shape by a powder molding machine, and pressed into shape The material is placed in an atmosphere rotary kiln sintering furnace, in a hydrogen or nitrogen atmosphere, the temperature is raised at a heating rate of 10°C / min, and roasted at a constant temperature of 400°C for 5 hours, and then heated at a heating rate of 10°C / min, and roasted at a constant temperature of 680°C for...

Embodiment 2

[0041] Add 75.03 grams of ethanol solvent to the double-helix mixer, while stirring, add 46.15 grams of lithium hydroxide, 179.89 grams of ferrous oxalate, 115.03 grams of ammonium dihydrogen phosphate and 34.11 grams of ammonium lignosulfonate, and continue to stir for 7 hours until fully reacted , mixed evenly to generate Fe-containing 2+ 、PO 4 3- , Li + The liquid phase colloid mixture, and then vacuum-dried at 60°C; the dried material was put into a ball mill container filled with hydrogen or nitrogen atmosphere and ball milled for 5 hours, and the ball milled material was pressed into a disc shape by a powder molding machine, and pressed into shape The material is placed in an atmosphere rotary kiln sintering furnace, in a hydrogen or nitrogen atmosphere, the temperature is raised at a heating rate of 10°C / min, and roasted at a constant temperature of 400°C for 5 hours, and then heated at a heating rate of 10°C / min, and roasted at a constant temperature of 680°C for 12 ...

Embodiment 3

[0043] Add 77.21 grams of ethanol solvent to the double-helix mixing mixer, while stirring, add 56.03 grams of lithium oxalate, 179.89 grams of ferrous oxalate, 115.03 grams of ammonium dihydrogen phosphate and 35.09 grams of ammonium lignosulfonate, and continue to stir for 7 hours until fully reacted, Mix evenly to generate Fe-containing 2+ 、PO 4 3- , Li + The liquid phase colloid mixture, and then vacuum-dried at 60°C; the dried material was put into a ball mill container filled with hydrogen or nitrogen atmosphere and ball milled for 5 hours, and the ball milled material was pressed into a disc shape by a powder molding machine, and pressed into shape The material is placed in an atmosphere rotary kiln sintering furnace, in a hydrogen or nitrogen atmosphere, the temperature is raised at a heating rate of 10°C / min, and roasted at a constant temperature of 400°C for 5 hours, and then heated at a heating rate of 10°C / min, and roasted at a constant temperature of 680°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com