A method for preparing a cementitious material reducing admixture from a cationic polymer

A technology of cationic polymers and adhesive reducers, which is applied in the field of building materials, can solve the problems of limiting the large-scale application and promotion of adhesive reducers, limiting the development and application range of adhesive reducers, etc., and achieving avoidance of competitive adsorption, good designability, and improved The effect of dispersion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

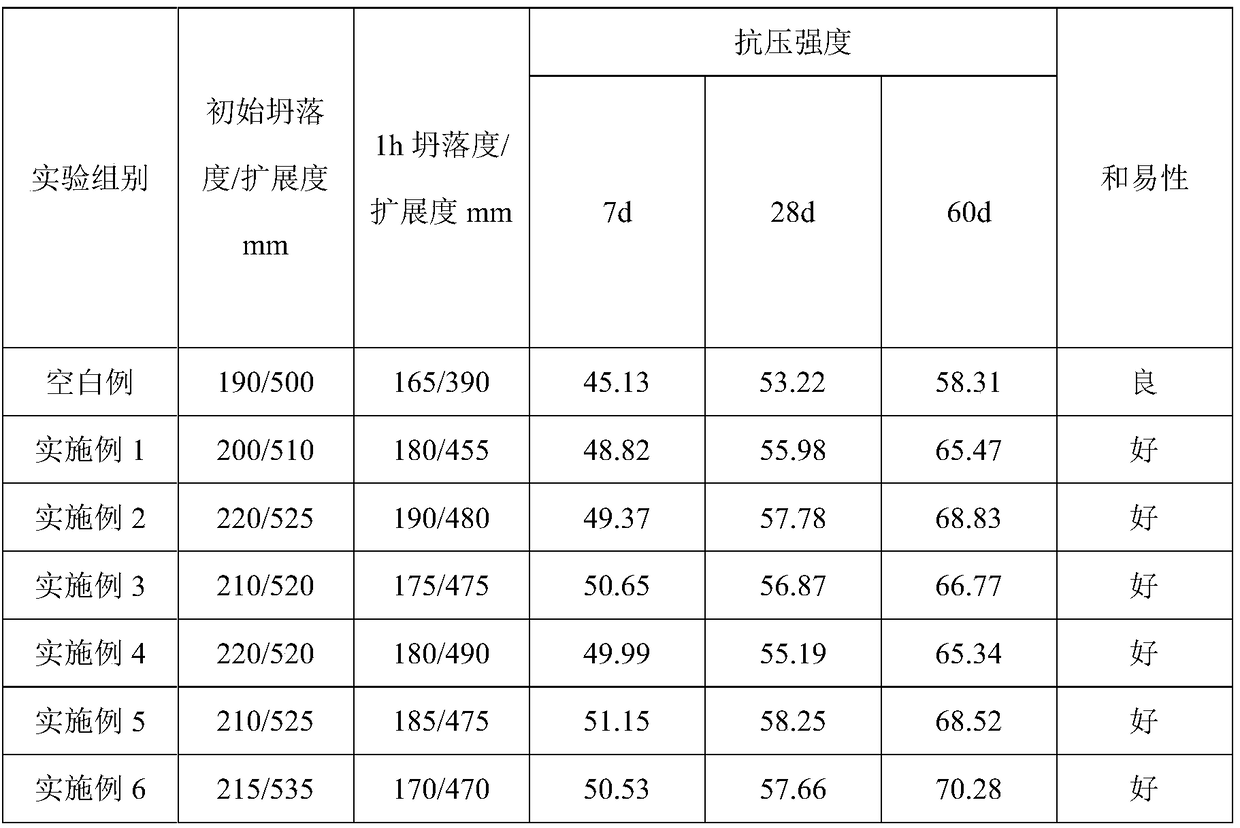

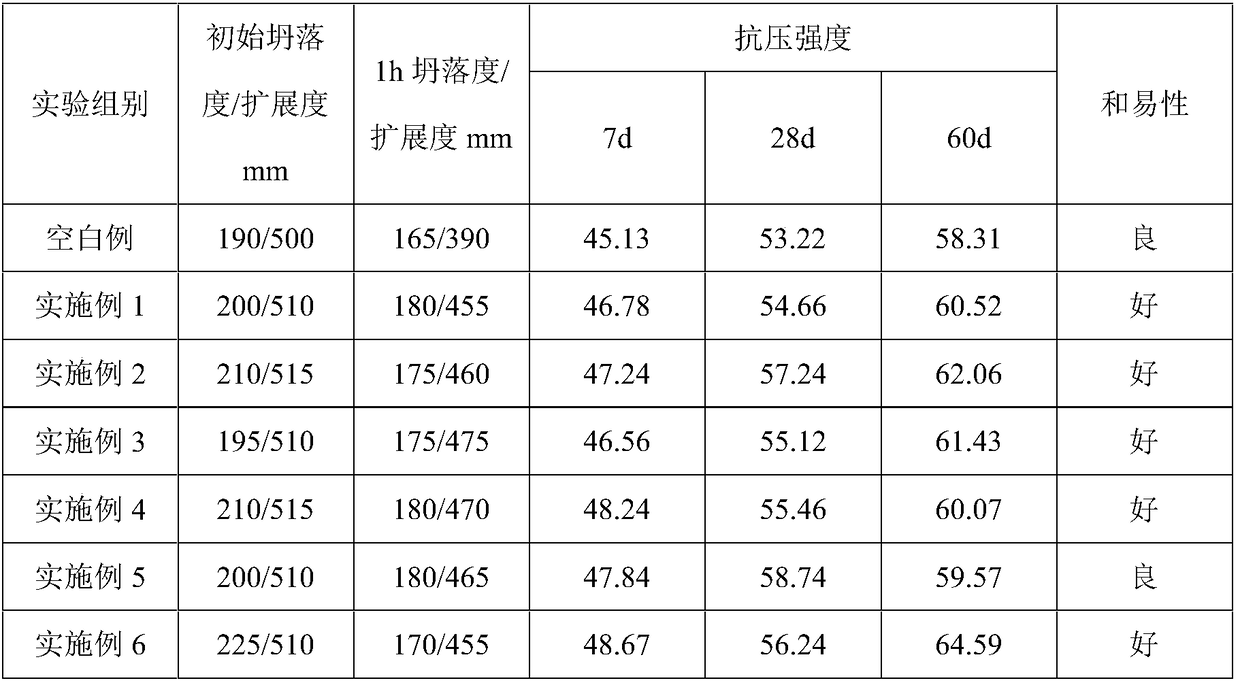

Examples

Embodiment 1

[0035] Embodiment 1 (each component consumption is parts by weight)

[0036] 1, the preparation of cationic polymer: the preparation method of cationic polymer is carried out as follows:

[0037] 1), 10 parts of 2-acrylamide-2-methylpropanesulfonic acid, 6 parts of dimethyl-vinyl phosphate, 0.5 parts of acrylic anhydride, 7 parts of sodium hypophosphite monohydrate and 30 parts of water are added to the reaction In the kettle, stir to dissolve;

[0038] 2), measure the temperature in the kettle, control the temperature at 5°C, after the temperature is stable, add 2 parts of ammonium persulfate at one time;

[0039] 3), after adding ammonium persulfate for 5 minutes, start to drop solution A and solution B successively. After solution A is added, start to add solution B dropwise within 10 minutes. The time for adding solution B is 0.5 hours, and the time for adding solution A is 1 hour; solution A consisted of 1 part thioglycolic acid and 20 parts water, solution B consisted ...

Embodiment 2

[0042] Embodiment 2 (each component consumption is parts by weight)

[0043] 1, the preparation of cationic polymer: the preparation method of cationic polymer is carried out as follows:

[0044] 1), 11 parts of N-methyl-1-ethylene sulfonamide, 5.5 parts of ethylene glycol methacrylate phosphate, 1 part of decenyl succinic anhydride, 6.8 parts of sodium hypophosphite monohydrate and 25 parts of water Add to the reaction kettle, stir to dissolve;

[0045] 2), measure the temperature in the kettle, control the temperature at 8°C, after the temperature is stable, add 2.4 parts of ammonium persulfate at one time;

[0046] 3), after adding ammonium persulfate for 5 minutes, start to drop solution A and solution B successively. After solution A is added, start to add solution B dropwise within 10 minutes. The time for adding solution B is 1.3 hours, and the time for adding solution A is 1.8 hours; solution A consists of 1-4 parts of thioglycolic acid and 24 parts of water, solutio...

Embodiment 3

[0049] Embodiment 3 (each component consumption is parts by weight)

[0050] 1, the preparation of cationic polymer: the preparation method of cationic polymer is carried out as follows:

[0051] 1) Add 12 parts of N-methylolacrylamide, 4.8 parts of bistrimethylsilylated vinyl phosphate, 2 parts of crotonic anhydride, 6.4 parts of sodium hypophosphite monohydrate and 22 parts of water into the reactor in, stir to dissolve;

[0052] 2), measure the temperature in the kettle, control the temperature at 12°C, after the temperature is stable, add 2.8 parts of ammonium persulfate at one time;

[0053] 3), after adding ammonium persulfate for 5 minutes, start to drop solution A and solution B successively. After solution A is added, start to add solution B dropwise within 10 minutes. The time for adding solution B is 1.7 hours, and the time for adding solution A is 2.2 hours; solution A consists of 2 parts of thioglycolic acid and 28 parts of water, solution B consists of 7 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com