Lubricating oil composition for integrated electric drive assembly speed reducer

A technology of lubricating oil composition and assembly reducer, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem that the reducer cannot improve shear resistance stability, etc., achieve excellent pitting corrosion protection, excellent anti-wear, avoid The effect of competitive adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

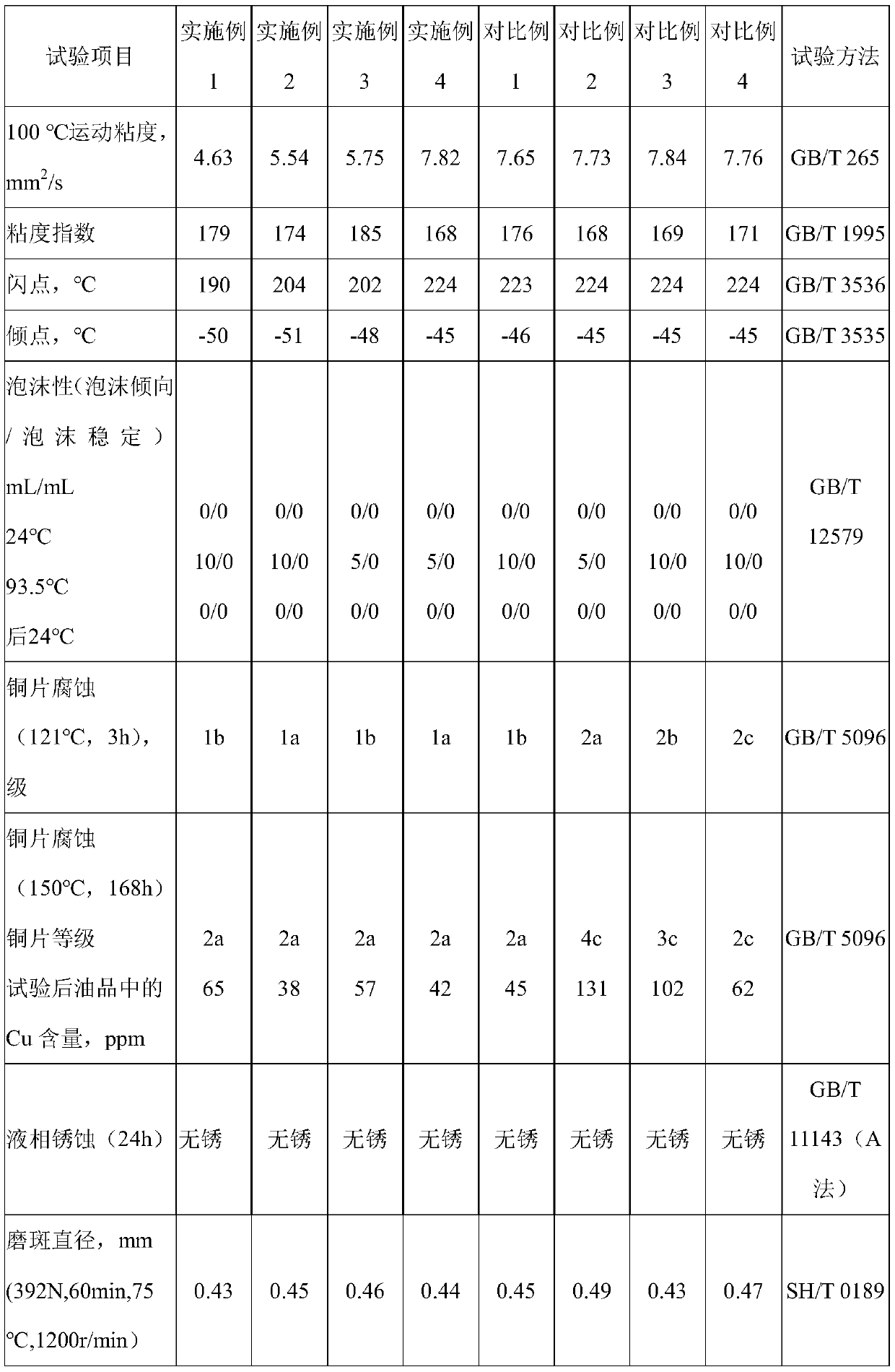

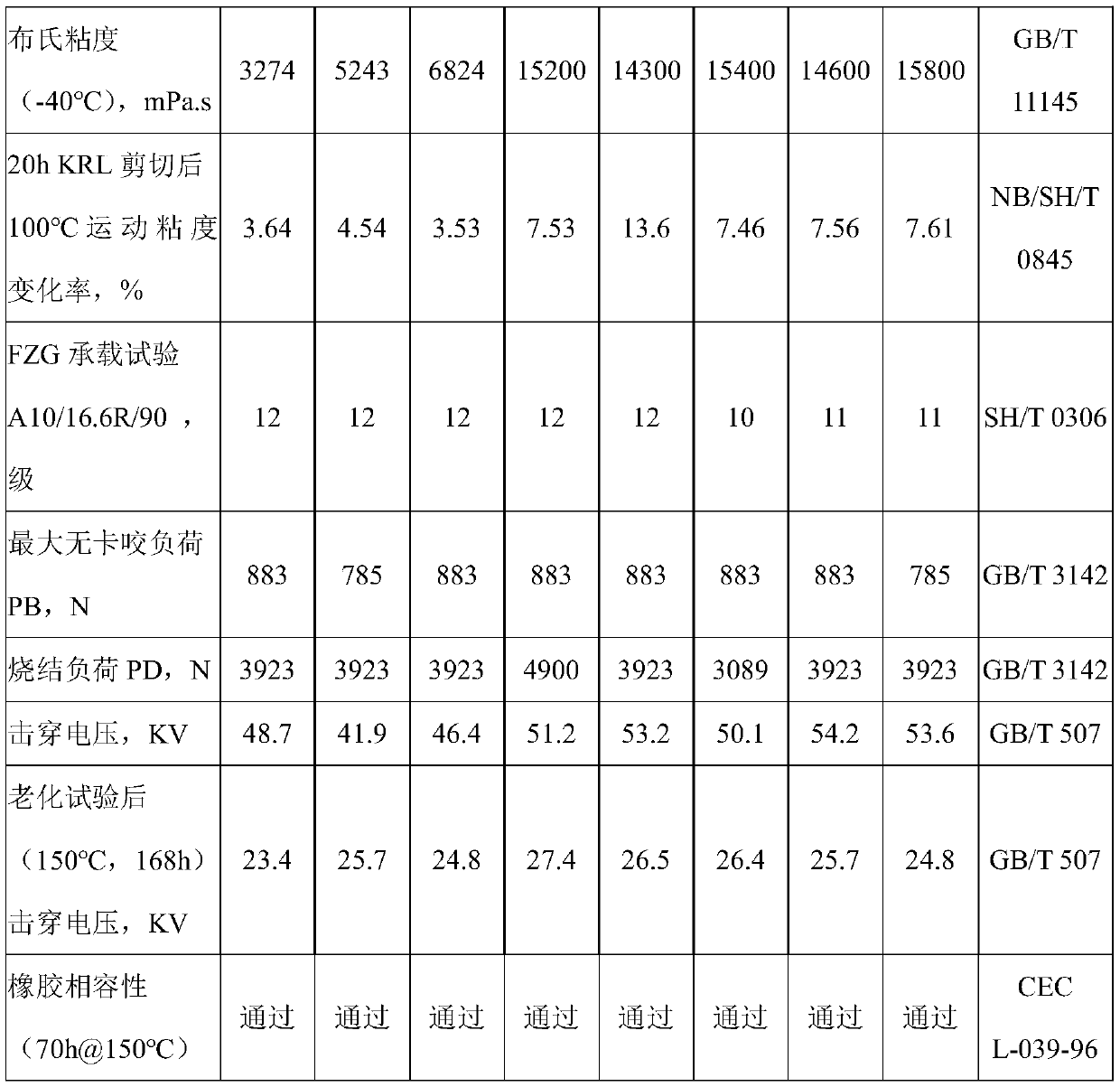

[0022] A lubricating oil composition for an integrated electric drive assembly reducer in this embodiment is blended from the components shown in the following Table 1 in weight percentage:

[0023] Table 1

[0024] components weight percentage III hydrogenated base oil 70SN 68% PAO2 15% Viscoplex 12-075 9% Complex agent Hitec 3080 7.0% Reinforcing agent Irgalube 353 0.2% Strengthening agent VANLUBE 601 0.3% Pour point depressant Viscoplex 1-300 0.5%

Embodiment 2

[0026] The lubricating oil composition for the reducer of the integrated electric drive assembly in this embodiment is blended from the components shown in the following table 2 in percentage by weight:

[0027] Table 2

[0028] components weight percentage III hydrogenated base oil 70N 51% III hydrogenated base oil 150N 36.55% Viscoplex 12-095 4% Compounding agent Infineum T4311 8% Reinforcing agent Irgalube 353 0.05% Strengthening agent VANLUBE 601 0.1% Pour point depressant Viscoplex 1-300 0.3%

Embodiment 3

[0030] The lubricating oil composition for the reducer of the integrated electric drive assembly in this embodiment is blended from the components shown in the following table 3 in percentage by weight:

[0031] table 3

[0032] components weight percentage III hydrogenated base oil 70SN 49.3% III hydrogenated base oil 100N 35% Viscoplex 12-075 9.0% Compounding agent Lubrizol GO3329 6% Reinforcing agent Irgalube 353 0.1% Strengthening agent VANLUBE 601 0.2% Pour point depressant Viscoplex 1-248 0.4%

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear stability index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com