Method for purifying thiocyanate ions in cyanide-containing wastewater by means of flocculation and sedimentation

A technology for thiocyanate and cyanide wastewater, which is applied in chemical instruments and methods, precipitation treatment, water pollutants, etc., can solve the problems of high treatment cost, increase the dosage of chemicals, limit the application of oxidation process, etc., and achieves simple process and chemical consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

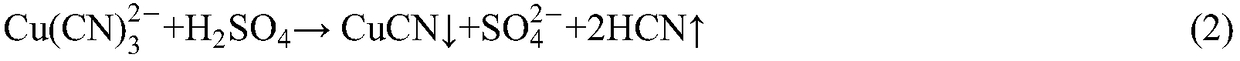

Method used

Image

Examples

Embodiment 1

[0032] Weigh 2L of cyanidation leaching gold-removal lean liquid, the concentration of thiocyanate in the liquid is 4.23g / L, add concentrated sulfuric acid to adjust the pH value of the solution to about 2.5, aeration stripping for 1h, the carrier gas is adsorbed by lye and then regenerated cyanide sodium. After acidification, 1.5 L of the filtrate was collected by liquid filtration, 12 g of solid ferric sulfate was added, and the mixture was stirred for 30 min and filtered. Take 1L of the filtrate and add lime milk to adjust the pH value to about 7.5, add 6g of solid polymerized ferric sulfate, add 300g of waste mineral powder with -400 mesh accounting for more than 80% after full stirring, stir and flocculate and settle until the solution red disappears, and the treatment process is completed after filtration . After treatment, the concentration of thiocyanate in the tail liquor was 0.68g / L, and the theoretical removal rate reached 83.9%.

Embodiment 2

[0034] Weigh 2L of cyanidation leaching gold removal lean liquid, the concentration of thiocyanate in the liquid is 5.81g / L, add concentrated sulfuric acid to adjust the pH value of the solution to about 2.2, aeration and stripping for 1h, the carrier gas is adsorbed by lye and then regenerated cyanide sodium. After acidification, 1.5 L of the filtrate was collected by liquid filtration, 15 g of solid ferric sulfate was added, and the mixture was stirred for 30 min and then filtered. Take 1L of the filtrate and add lime milk to adjust the pH value to about 8.3, add 8g of solid polymerized ferric sulfate, add 400g of -400 mesh waste mineral powder accounting for more than 80% after full stirring, stir and flocculate and settle until the solution red disappears, and the treatment process is completed after filtration . After treatment, the concentration of thiocyanate in the tail liquor was 0.77g / L, and the theoretical removal rate reached 86.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com