Preparation method of high efficiency controllable polycarboxylic acids series cement grinding aid

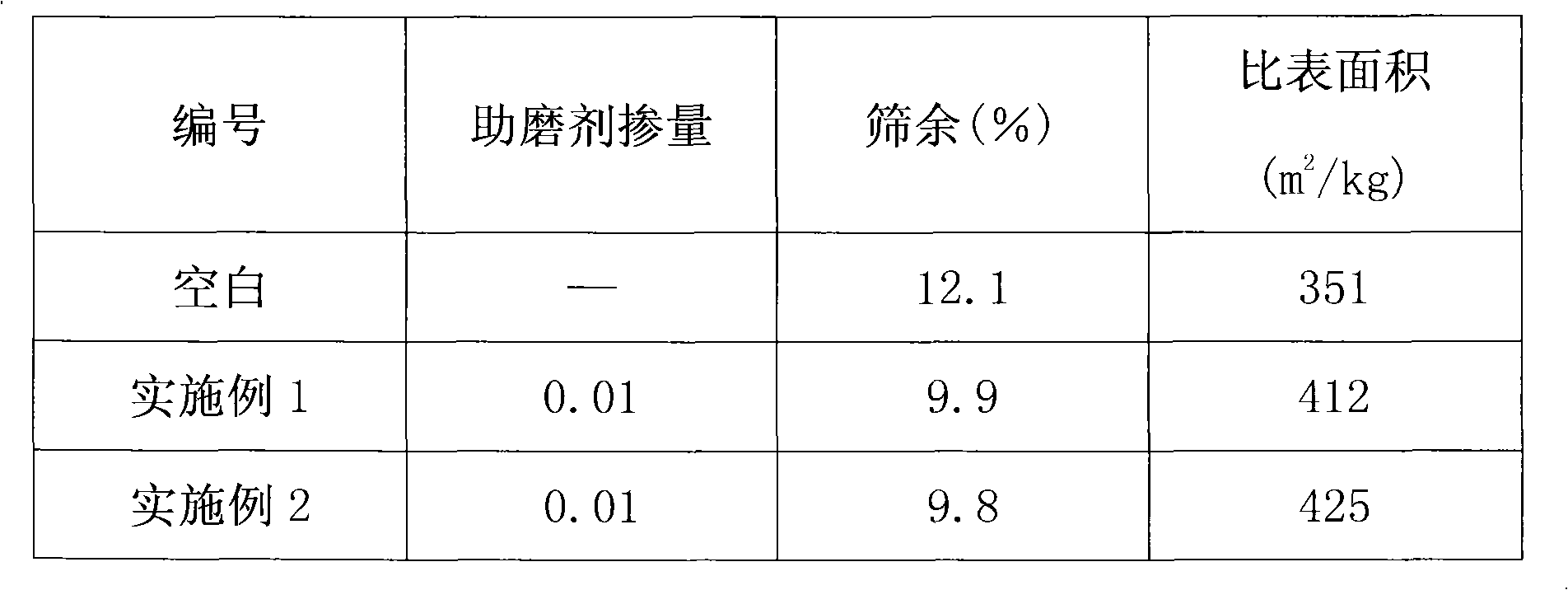

A cement grinding aid and polycarboxylic acid-based technology, which is applied in the field of high-efficiency and controllable polycarboxylic acid-based cement grinding aid preparation, can solve the problems of large fluctuation of use effect, narrow adaptability, poor stability of grinding aid, etc. , to achieve the effect of reducing sieve residue, stable application performance and increasing compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

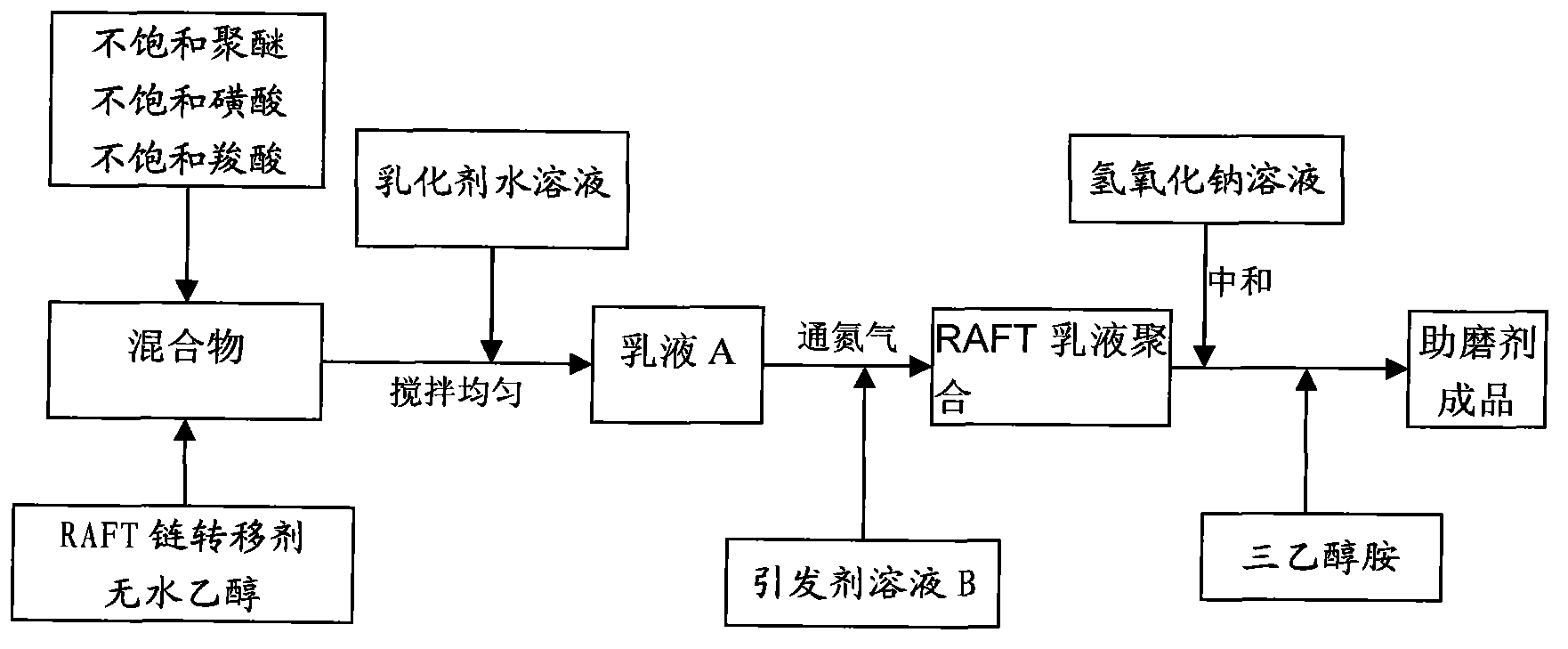

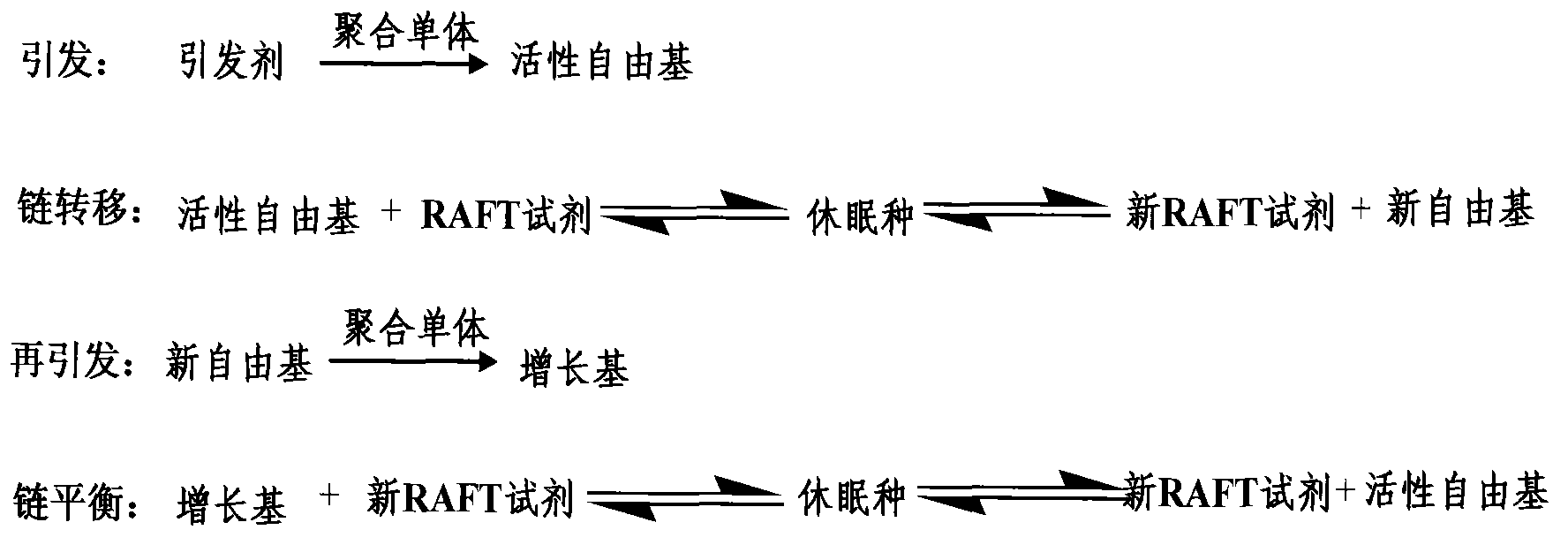

Method used

Image

Examples

Embodiment 1

[0026] Put 8.2 parts of allyl polyoxyethylene ether (800), 3.3 parts of sodium methacrylate, 3.5 parts of methacrylic acid, 0.5 parts of benzyl dithiobenzoate, and 10 parts of absolute ethanol in a reaction kettle and mix them , then add 64.5 parts of aqueous solution containing 15% sodium dodecylbenzenesulfonate, stir and mix evenly, and make emulsion A; make solution B with 0.8 parts of potassium persulfate and 9.2 parts of water; pass nitrogen in emulsion A Under certain conditions, when the temperature rises to 85°C, add the above-mentioned solution B dropwise, adjust the flow meter for 2 hours, and continue the reaction for 10 hours to obtain a light yellow liquid; after the reaction, add a 30% sodium hydroxide solution Neutralize until the pH is 7.0±0.5, then add triethanolamine accounting for 7% of the total mass of the reaction system into the solution, and stir evenly to obtain the finished product.

Embodiment 2

[0028] 18.5 parts of methallyl polyoxyethylene ether (600), 10.2 parts of 2-acrylamido-2-methylpropanesulfonic acid, 1.3 parts of acrylic acid, 0.8 parts of cumyl dithiobenzoate, 10 parts Put absolute ethanol in the reaction kettle and mix, then add 49.2 parts of aqueous solution containing 30% OP-10, stir and mix evenly, and make emulsion A; make solution B with 1.0 parts of potassium persulfate and 9.0 parts of water; Under the condition of flowing nitrogen in A, when the temperature is raised to 80°C, add the above prepared solution B dropwise, adjust the flow meter to finish dripping in 1.5h, continue the reaction for 15h, and obtain a light yellow liquid; after the reaction, add a mass fraction of 30 % sodium hydroxide solution to neutralize to a pH of 7.0±0.5, then add triethanolamine accounting for 3% of the total mass of the reaction system to the solution, and stir evenly to obtain the finished product.

Embodiment 3

[0030] Put 16.0 parts of isopentenol polyoxyethylene ether (1000), 2.3 parts of sodium allyl sulfonate, 1.7 parts of acrylic acid, 0.6 parts of benzyl dithiobenzoate, and 10 parts of absolute ethanol in a reaction kettle and mix them. Then add 59.4 parts of aqueous solution dissolved with 20% sodium dodecylbenzenesulfonate, stir and mix evenly, and make emulsion A; make solution B with 1.0 parts of ammonium persulfate and 9.0 parts of water; Under certain conditions, when the temperature is raised to 70°C, add the prepared solution B dropwise, adjust the flowmeter to finish dripping in 1.5 hours, and continue the reaction for 15 hours to obtain a light yellow liquid; after the reaction is completed, add sodium hydroxide with a mass fraction of 30% The solution is neutralized until the pH is 7.0±0.5, and then triethanolamine accounting for 5% of the total mass of the reaction system is added to the solution, and stirred evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com