Copper nanowire and preparation method thereof

A nano-copper wire, copper salt technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor uniformity of nano-metal wires, damage to conductivity and structure, and high cost of synthesis methods , to achieve the effect of simple equipment, low cost, good dispersibility and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of nano copper wire of the present embodiment comprises the following steps:

[0039] (1) Take 0.5L 1mol / L calcium hydroxide solution in the reactor, start the magnetic stirrer and ultrasonic generator, heat to 50°C, add 20μL 0.01mol / L copper acetate solution and stir evenly;

[0040] (2) Take 200mL of 0.005mol / L potassium borohydride solution and 1×10 -3 mol / L polyvinylpyrrolidone solution 25mL is mixed evenly, then added to the solution obtained in step (1) and stirred evenly;

[0041] (3) Add 1L of 0.01mol / L copper acetate solution at a rate of 2.0mL / min and keep reacting for 0.5 hours at a reaction temperature of 50°C;

[0042] (4) The product obtained in step (3) is centrifuged and washed with absolute ethanol and distilled water to obtain the nano copper wire.

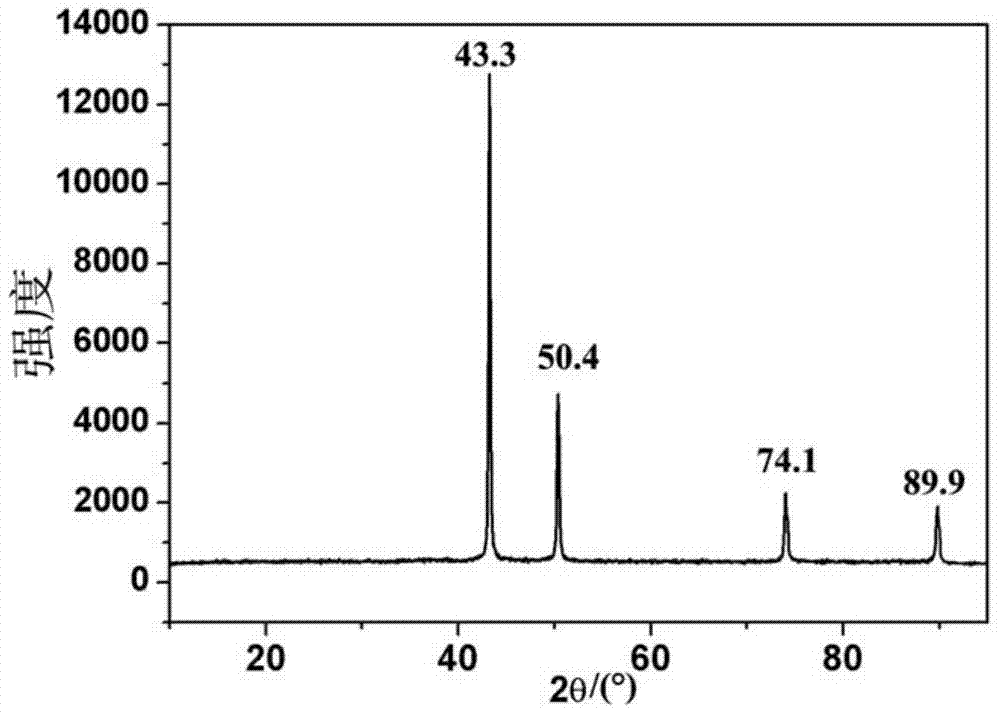

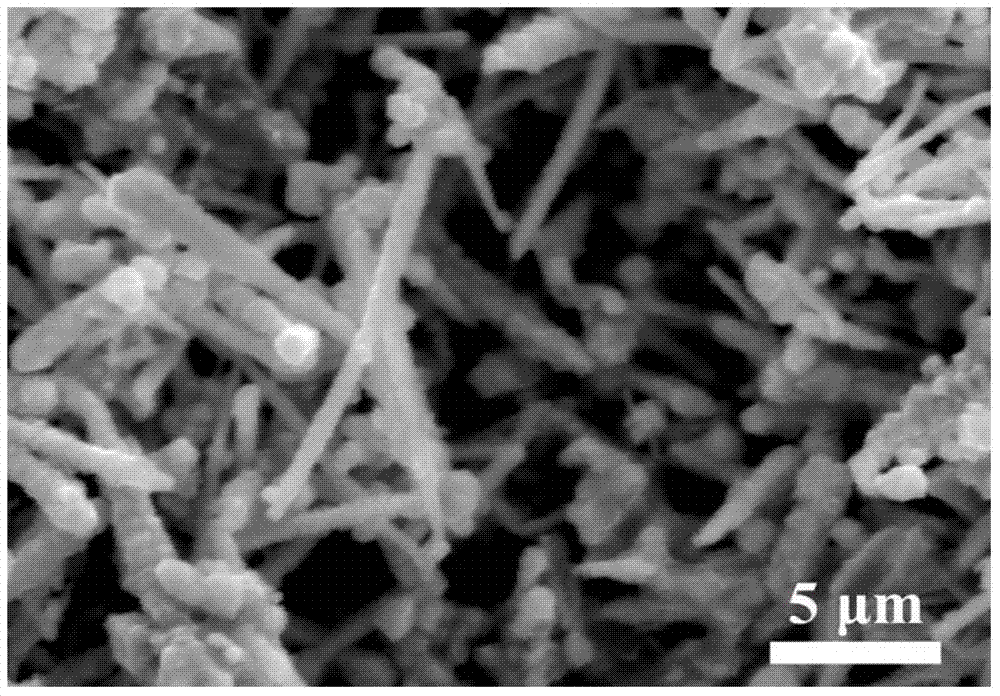

[0043] The above product was analyzed by X-ray diffraction (XRD, such as figure 1 shown) and EDS (as Figure 8 Shown) analysis is pure copper; SEM observes the morphology and str...

Embodiment 2

[0045] The preparation method of nano copper wire of the present embodiment comprises the following steps:

[0046] (1) Take 0.2L 5mol / L sodium hydroxide solution in the reactor, start the magnetic stirrer and ultrasonic generator, heat to 40°C, add 40μL 0.0005mol / L copper sulfate solution and stir evenly;

[0047] (2) Take 10mL of 0.005mol / L sodium borohydride solution and 1×10 -3 mol / LC 13 ~C16 Mix 20mL sodium alkyl sulfonate solution evenly, add it to the solution obtained in step (1), and stir evenly;

[0048] (3) Add 1L of 0.05mol / L copper sulfate solution at a rate of 0.4mL / min and keep reacting for 2 hours at a reaction temperature of 40°C;

[0049] (4) Centrifuge the reaction product obtained in step (3), wash it with absolute ethanol and distilled water to obtain the copper nanowire of this embodiment.

[0050] The X-ray diffraction analysis (XRD) figure is similar to that of Example 1; the morphology and structure of the nano-copper wires obtained in this example ...

Embodiment 3

[0052] The preparation method of nano copper wire of the present embodiment comprises the following steps:

[0053] (1) Take 0.1L 8mol / L potassium hydroxide solution in the reactor, start the magnetic stirrer and ultrasonic device, and heat to 70°C, add 60μL 0.01mol / L copper nitrate solution and stir evenly;

[0054] (2) Take 300mL of 0.015mol / L glucose solution and 1×10 -4 mol / L sodium lauryl sulfate 15mL is mixed evenly, then added to the solution obtained in step (1), and stirred evenly;

[0055] (3) Add 1L of 0.01mol / L copper nitrate solution at a rate of 1.2mL / min and keep reacting for 3 hours at a reaction temperature of 70°C;

[0056] (4) Centrifuge the product obtained in step (3), wash it with absolute ethanol and distilled water to obtain the nano copper wire of this example.

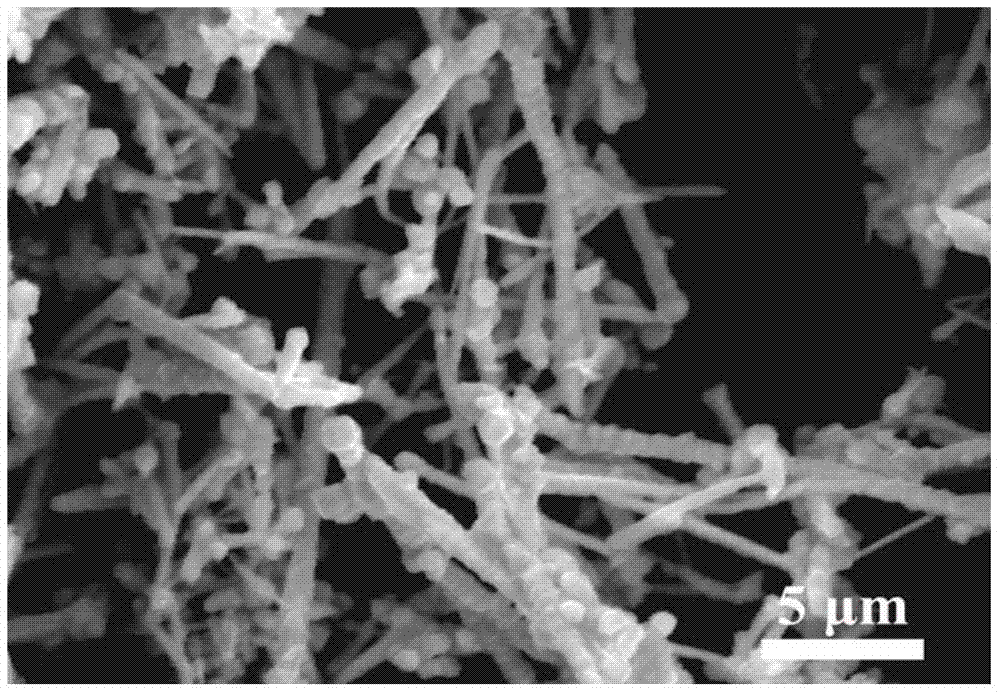

[0057] The X-ray diffraction analysis (XRD) figure is similar to that of Example 1; the morphology and structure of the nano-copper wires obtained in this example are observed by SEM, as F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com