Lightweight high-strength concrete doped with recycled aggregate, machine-made sand and stone powder

A technology of high-strength concrete and recycled aggregate, applied in the field of concrete, can solve the problems of poor repeatability of concrete work performance and mechanical performance, uneven quality and quality of machine-made sand, poor gradation and particle shape of machine-made sand, etc. Low, low density, solve the effect of stacking and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

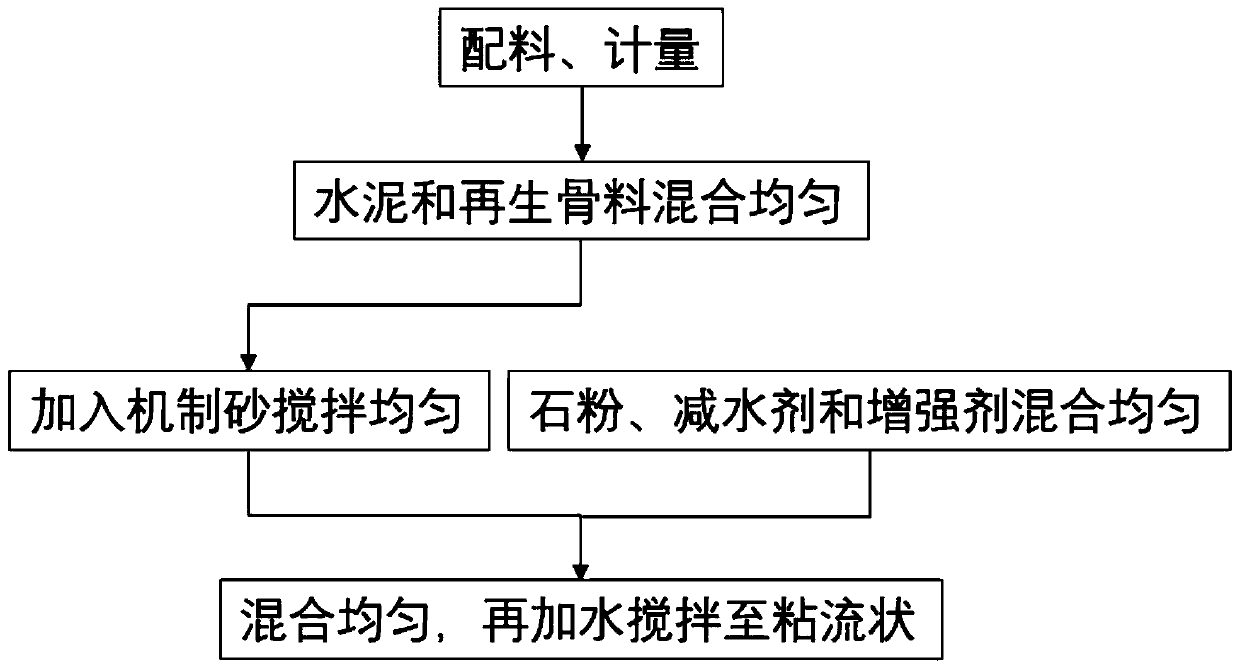

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with specific examples.

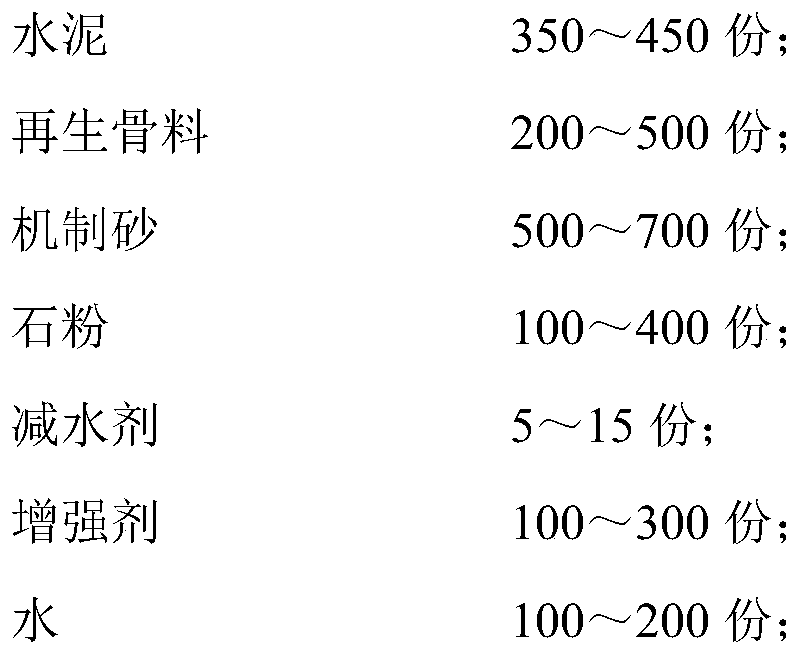

[0032] The raw materials of the lightweight high-strength concrete mixed with recycled aggregate, machine-made sand and stone powder of the present invention include the following components in parts by mass: 350-450 parts of cement, 200-500 parts of recycled aggregate, 500-700 parts of machine-made sand, and 100 parts of stone powder ~400 parts, 5~15 parts of water reducing agent, 100~300 parts of strengthening agent and 100~200 parts of water.

[0033] Among them, the particle size of machine-made sand is less than 2.5mm, the content of stone powder is 16%-17%, and the apparent density is 2-3g / cm 3 , the porosity is 28% to 29%, and the fineness modulus is 2 to 2.5; the recycled aggregate is formed by crushing and screening the waste concrete in the construction waste, and the particle diameter of the recycled aggregate is less than 25mm, and the ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com