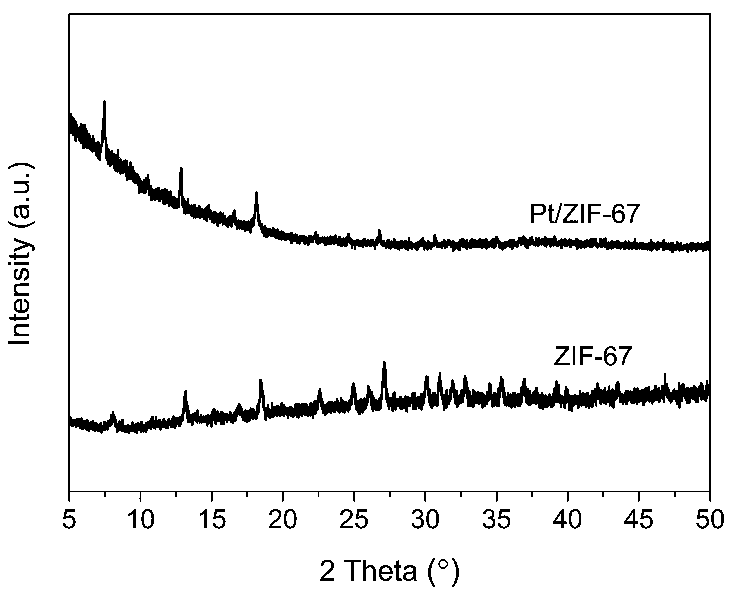

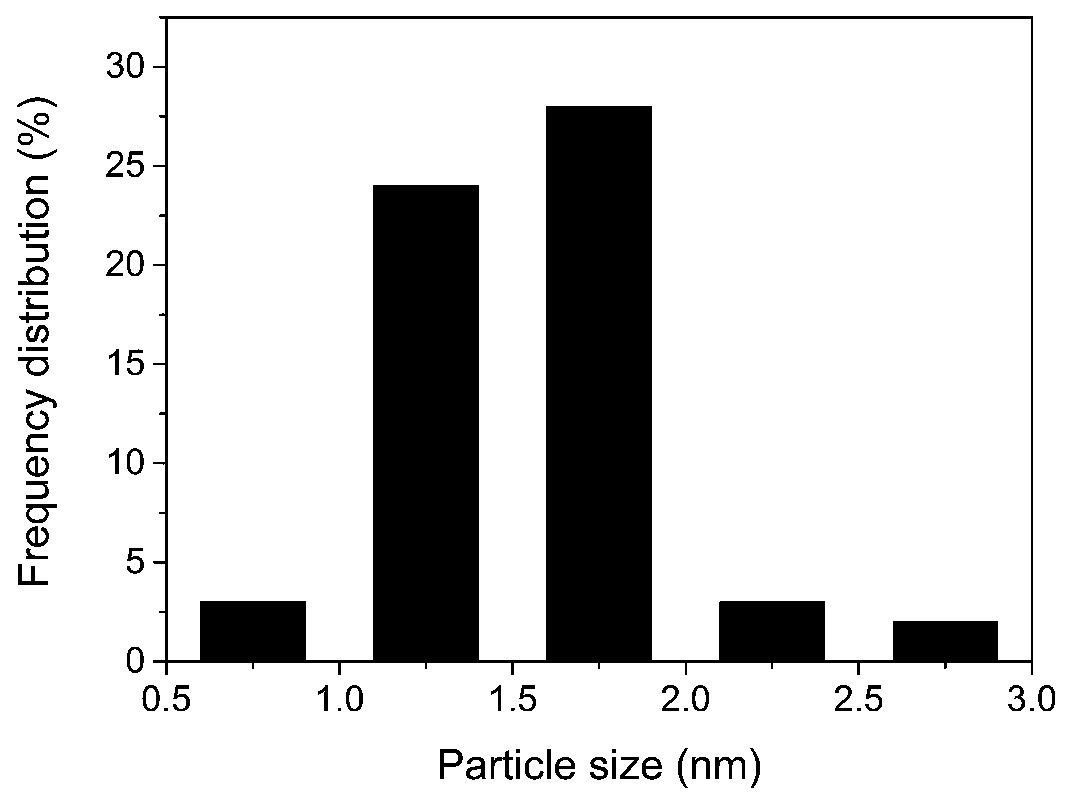

Pt/ZIF-67 composite used for catalyzing hydrolysis of ammonia borane for hydrogen production

A technology for catalyzing ammonia borane and ZIF-67, applied in the energy field, can solve the problems of low TOF value and high activation energy, and achieve the effects of inhibiting agglomeration, low cost and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The specific operation steps of the Pt / ZIF-67 composite material used to catalyze the hydrolysis of ammonia borane to produce hydrogen are as follows:

[0025] Step 1) Preparation and activation of ZIF-67, add 1 mmol of cobalt acetate tetrahydrate and 20 mmol of 2-methylimidazole into 20 mL of water, mix well by ultrasonic, then put into autoclave, put into oven, keep constant temperature heat up to 120 o C initiates the reaction, and the reaction time is 18 h. After the reaction system is slowly cooled to room temperature, the product is taken out and washed repeatedly with absolute ethanol and deionized water. o After drying under C, ZIF-67 was obtained, and the resulting ZIF-67 was vacuum-conditioned at 150 o C, incubated for 12 h for activation to obtain activated ZIF-67;

[0026] Step 2) Loading of Pt nanoparticles, 100 mg of activated ZIF-67 was added to 15 mL of water, ultrasonically dispersed for 40 min, then 5 mg of chloroplatinic acid was added to the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com