Preparation method for two-dimensional supported nanometer magnesium hydride hydrogen storage material

A hydrogen storage material and load-type technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of low yield of nano-MgH, no way to make large-scale preparation, hidden safety hazards, etc., to achieve low cost, Low energy consumption and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

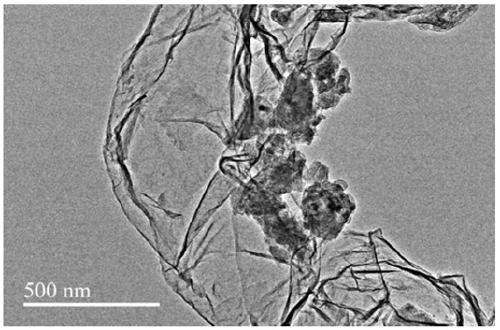

[0049] Two-dimensional supported nano-magnesium hydride MgH 2 Preparation of @25wt.% GR.

[0050] With 99% dibutyl magnesium dissolved in 1M ether and hexane solution as raw material, graphene (GR) as two-dimensional carrier, according to MgH 2 : GR=3:1 mass ratio, (the molar ratio is 1:0.75) calculate the amount of raw materials (please indicate the molar ratio of metal organic compound and graphene). Under the protection of high-purity argon (99.999%), dibutylmagnesium and graphene were placed in the ball mill tank (250ml) of the ball mill, and the ball-to-material ratio in the ball mill process was 40:1. Before ball milling, evacuate the spherical tank to a vacuum of 1×10 3 pa, then filled with hydrogen gas with a purity of ≥99% and 5.0 MPa, and then ball milled at room temperature for 24 hours at a rotational speed of 200 rpm to obtain a suspension of the reaction product. The suspension of the ball mill reaction product was suction filtered; then the suction filtered s...

Embodiment 2

[0054] Two-dimensional supported nano-magnesium hydride MgH 2 Preparation of @25wt.% GR.

[0055] With 99% dibutyl magnesium dissolved in 1M ether and hexane solution as raw material, graphene (GR) as two-dimensional carrier, according to MgH 2 :GR=3:1 mass ratio, (the molar ratio is 1:0.75) to calculate the amount of raw materials. Under the protection of high-purity argon (99.999%), dibutylmagnesium and graphene were placed in the ball mill tank (250ml) of the ball mill, and the ball-to-material ratio in the ball mill process was 40:1. Before ball milling, evacuate the spherical tank to a vacuum of 1×103pa, then fill it with hydrogen with a purity of ≥99% and 5.0 MPa, and then ball mill at room temperature for 24 hours at a rotational speed of 350rpm to obtain a product suspension. The suspension of the ball milling reaction product was suction filtered; then the suction filtered sample was vacuum dried at a temperature of 200°C and an air pressure of 1×102pa to obtain a t...

Embodiment 3

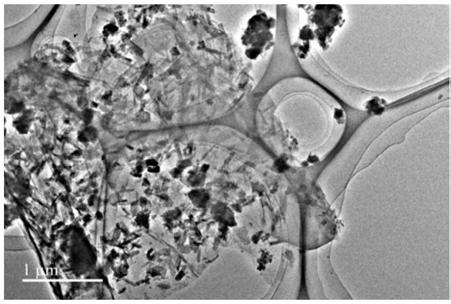

[0063] Two-dimensional supported nano-magnesium hydride MgH 2 Preparation of @80wt.% GR.

[0064] With 99% dibutyl magnesium dissolved in 1M ether and hexane solution as raw material, graphene (GR) as two-dimensional carrier, according to MgH 2 :GR=1:4.1 mass ratio (molar ratio is 1:9) to calculate the amount of raw materials. Under the protection of high-purity argon (99.999%), dibutylmagnesium and graphene were placed in the ball mill tank (250ml) of the ball mill, and the ball-to-material ratio in the ball mill process was 40:1. Before ball milling, evacuate the spherical tank to a vacuum of 1×10 3 pa, then filled with 2.0 MPa hydrogen with a purity of ≥99%, and then ball milled at room temperature for 10 h at a rotational speed of 200 rpm to obtain a product suspension. The suspension of the ball mill reaction product was suction filtered; then the suction filtered sample was vacuum dried at a temperature of 200°C and an air pressure of 1×10 5 pa, to obtain two-dimensi...

PUM

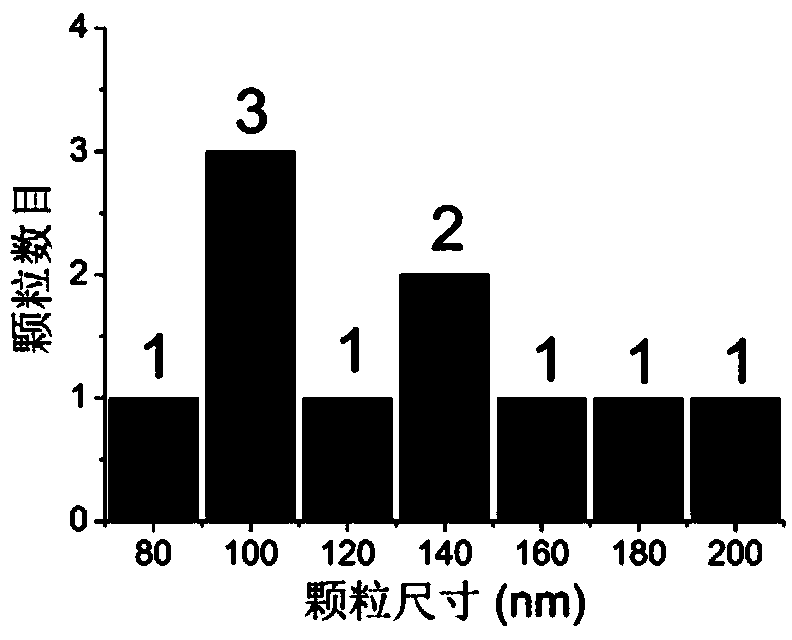

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com