A water bath heat exchange type hydrogen storage device for hydrogen kinetic energy engine vehicles

A hydrogen storage device and engine technology, applied in the field of hydrogen storage, can solve the problems of low heat dissipation rate, rising temperature of hydrogen storage tank, uneven heat exchange, etc., and achieve the goal of increasing heat dissipation rate, increasing heat absorption rate, and increasing hydrogen absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

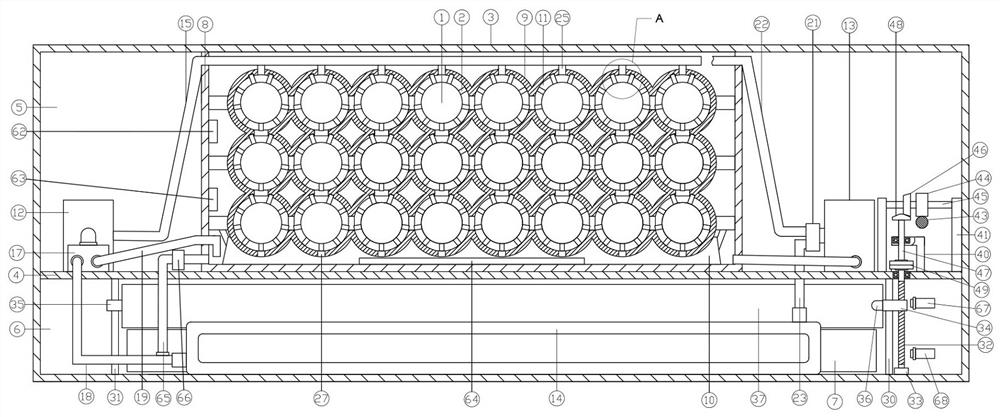

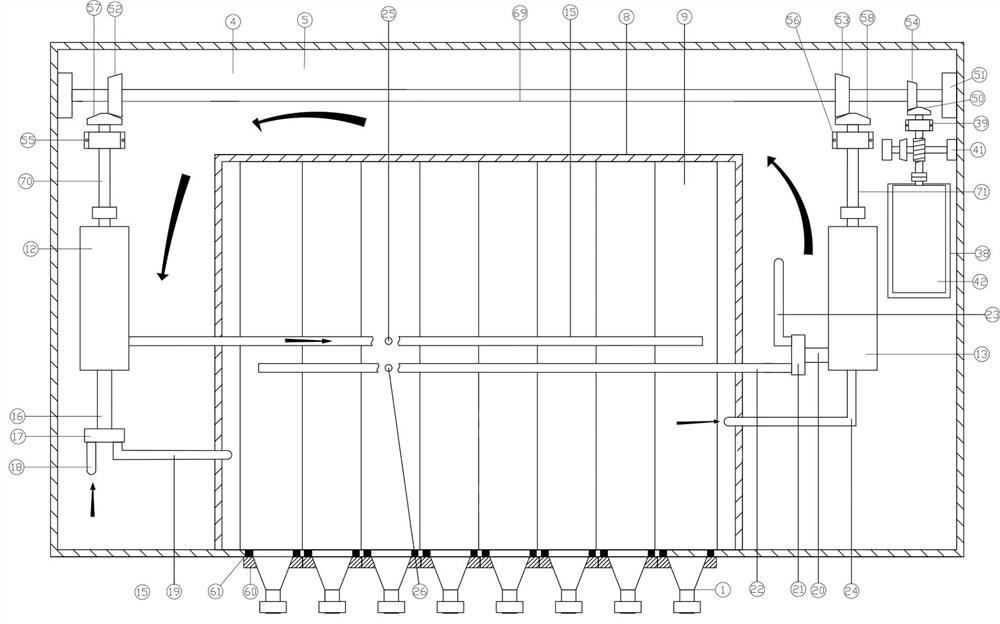

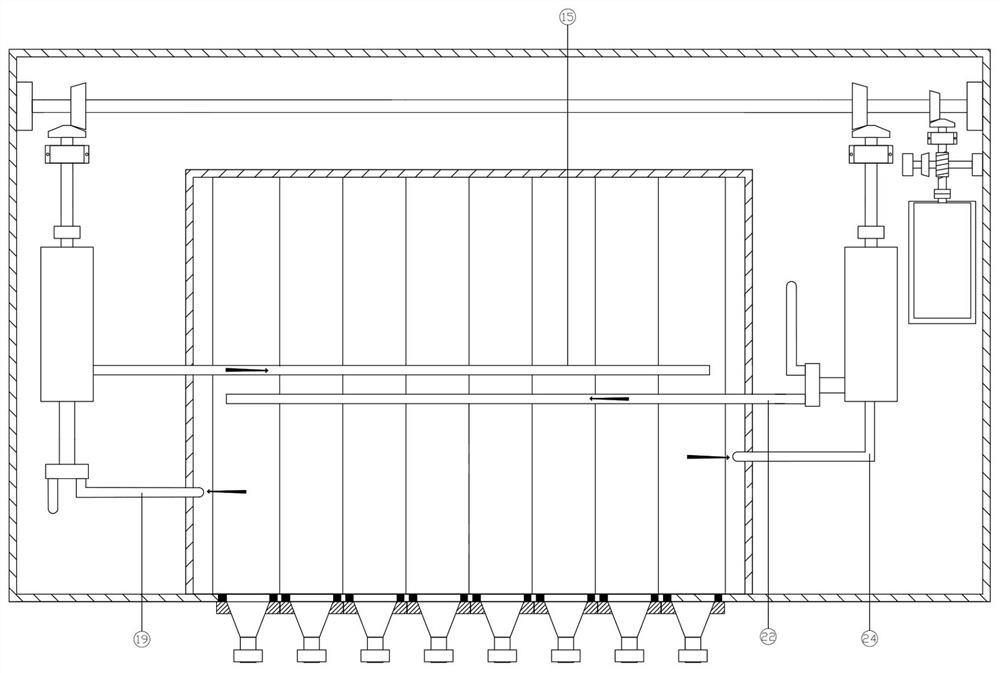

[0029] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7Shown: a water bath heat exchange type hydrogen storage device for a hydrogen kinetic energy engine vehicle, comprising: an alloy hydrogen storage tank 1, the outer wall of the alloy hydrogen storage tank 1 is fixed with a plurality of elongated heat exchange fins 2 in the circumferential direction, The length direction of the heat sheet 2 is the same as the axial direction of the alloy hydrogen storage tank 1; the outer casing 3 is fixed with a horizontal partition 4 inside the outer casing 3, and the partition 4 divides the outer casing 3 into an upper hydrogen storage chamber 5 and a lower hydrogen storage chamber. The air cooling chamber 6 is provided with a heat dissipation port 7; the inner casing 8 is fixedly installed in the hydrogen storage chamber 5; the heat exchange casing 9 is fixed by a fixing frame 10 Installed in the inner casing 8, the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com