A new energy composite material and its preparation method

A technology for hydrogen storage materials and mixed solutions, applied in chemical instruments and methods, inorganic chemistry, hydrogen, etc., can solve problems that restrict the development of hydrogen energy applications, small hydrogen storage capacity, and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

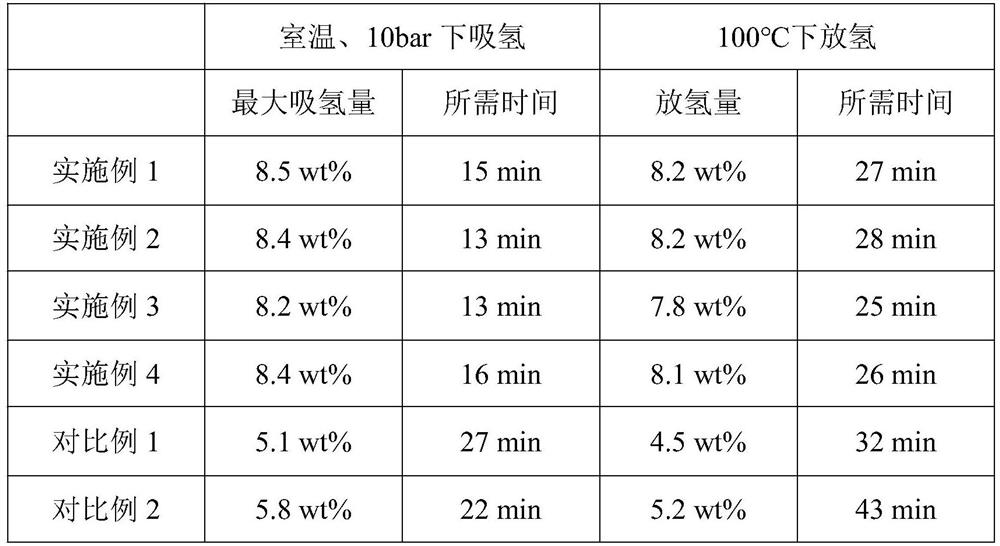

Examples

Embodiment 1

[0020] Step 1: adding lignocellulose into NaOH aqueous solution, stirring for 3 hours at a water bath temperature of 45° C. to obtain a suspension with a lignocellulose concentration of 5 wt%. The diatom frustule is ball-milled with a ball mill and passed through a 50-mesh sieve to obtain a powder, and then the diatom frustule powder is placed in deionized water for 20 minutes of ultrasonication. After the ultrasonic wave is completed, it is filtered and added to deionized water for 30 minutes to obtain a diatom frustule concentration of 8wt%. suspension. Then, with a mass ratio of lignocellulose and diatom frustule of 1:4, an appropriate amount of lignocellulose suspension and diatom frustule suspension were mixed and stirred at 80° C. for 8 hours, filtered after the stirring was completed, and the filter residue was washed with deionized water until Neutral, and then put the sample in a vacuum oven and dry at 73°C for 30h to obtain diatom frustules-lignocellulose material. ...

Embodiment 2

[0024] Step 1: adding lignocellulose into NaOH aqueous solution, and stirring for 3 hours at a water bath temperature of 50° C. to obtain a suspension with a lignocellulose concentration of 5 wt%. The diatom frustule is ball-milled with a ball mill and passed through a 50-mesh sieve to obtain a powder, then the diatom frustule powder is placed in deionized water for 15 minutes of ultrasonication, after the ultrasonic wave is completed, it is filtered and added to deionized water for 37 minutes to obtain a diatom frustule concentration of 8 wt%. suspension. Then, with a mass ratio of lignocellulose and diatom frustule of 1:3, an appropriate amount of lignocellulose suspension and diatom frustule suspension were mixed and stirred at 85° C. for 7 hours, filtered after the stirring was completed, and the filter residue was washed with deionized water until neutral, and then place the sample in a vacuum drying oven at 76° C. for 32 hours to obtain diatom frustules-lignocellulose ma...

Embodiment 3

[0028] Step 1: adding lignocellulose into NaOH aqueous solution, and stirring for 2 hours at a water bath temperature of 48° C. to obtain a suspension with a lignocellulose concentration of 5 wt%. The diatom frustule is ball-milled with a ball mill and passed through a 50-mesh sieve to obtain a powder, then the diatom frustule powder is placed in deionized water for 17 minutes, and after the ultrasound is completed, it is filtered and added to deionized water for 34 minutes to obtain a diatom frustule concentration of 8 wt%. suspension. Then, with a mass ratio of lignocellulose and diatom frustule of 1:3.5, an appropriate amount of lignocellulose suspension and diatom frustule suspension were mixed and stirred for 6 hours at 82°C, and filtered after the stirring was completed, and the filter residue was washed with deionized water until neutral, and then place the sample in a vacuum oven and dry at 80° C. for 34 hours to obtain diatom frustules-lignocellulose material.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com