Solar energy thermal utilization vacuum pipe hydrogen absorption material and using method thereof

A technology of hydrogen absorption material and solar heat, which is applied in the direction of using solid contact hydrogen separation, hydrogen separation, energy input, etc., can solve the problems of low hydrogen absorption rate and capacity of alloys, difficult to meet, and achieve fast hydrogen absorption rate and manufacturing process. Simple, low activation temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

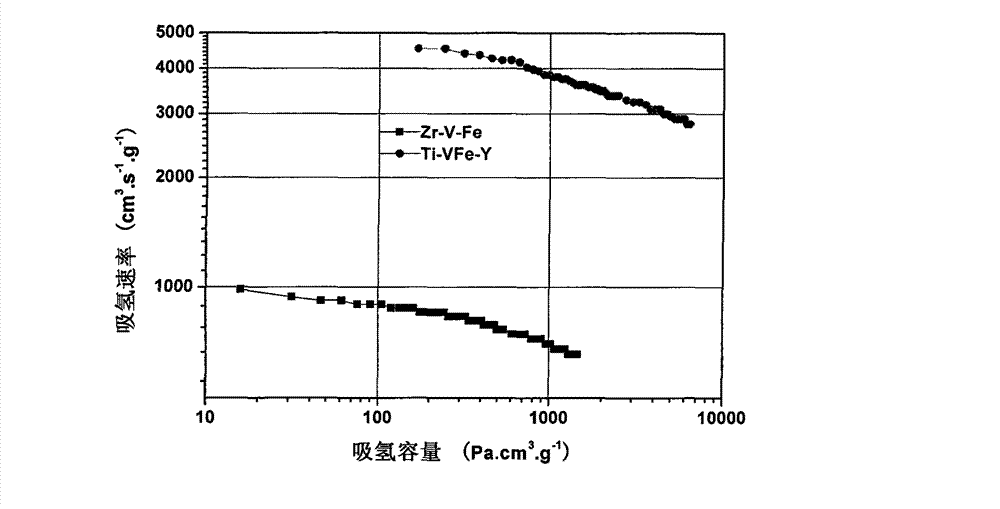

[0020] The raw materials are Ti (purity ≥ 99.5%), VFe (V content is 50%), Y (purity ≥ 99.5%), and the alloy is Ti 75 (VFe) 24.5 Y 0.5 Stoichiometric (i.e. according to Ti: 75wt%, VFe: 24.5wt%, Y: 0.5wt%, the same below), prepared by ordinary medium frequency induction vacuum smelting method, the smelted ingot is broken and ground under the protection of argon into - After the 100-mesh particle powder, take 0.32g and press it into a small piece of Ф6×3mm. According to GB / T 8763-1988, test the relationship between the hydrogen absorption rate and capacity of the alloy piece at room temperature as a function of time. For comparison, the Zr-V-Fe (Zr: 70wt%, V: 24.6wt%, Fe: 5.4wt%) alloy was smelted by the same process and pressed into small pieces of Ф6×3mm, and the hydrogen absorption performance was compared under the same conditions test. The test conditions are: the sample is at 450°C, better than 5×10 -3 Activation under Pa vacuum for 10 minutes, working temperature 25°C,...

Embodiment 2

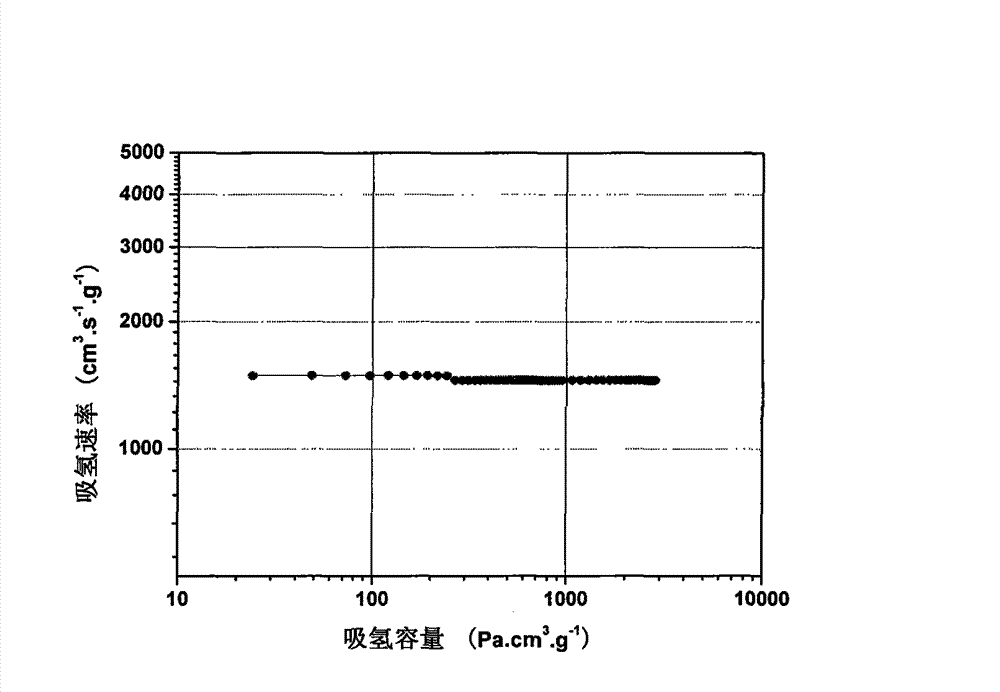

[0022] The raw materials are Ti (purity ≥ 99.5%), VFe (V content 80%), Mn (purity ≥ 98%), Y (purity ≥ 99.5%), and the alloy is based on Ti 51.5 (VFe) 36.5 mn 10.5 Y 1.5 Stoichiometric, prepared by ordinary medium-frequency induction vacuum melting method, the melted ingot is crushed, and ground into -100 mesh particle powder under the protection of argon. Take 0.32g and press it into a small piece of Ф6×3mm. According to GB / T 8763-1988, test the relationship between the hydrogen absorption rate and capacity of the alloy piece at room temperature as a function of time. Alloy flakes are better than 5×10 -3 Pa vacuum, activation at 200°C for 30 minutes. Test working pressure 2.7×10 -4 Pa, test results such as figure 2 Shown, visible, Ti 51.5 (VFe) 36.5 mn 10.5 Y 1.5 Alloy 25℃ to H 2 Hydrogen absorption rate S at 10 minutes 10 (cm 3 ·S -1 g -1 ) is 1491.7cm 3 ·S -1 g -1 , the hydrogen absorption rate is basically kept constant within 120 minutes, and the hydroge...

Embodiment 3

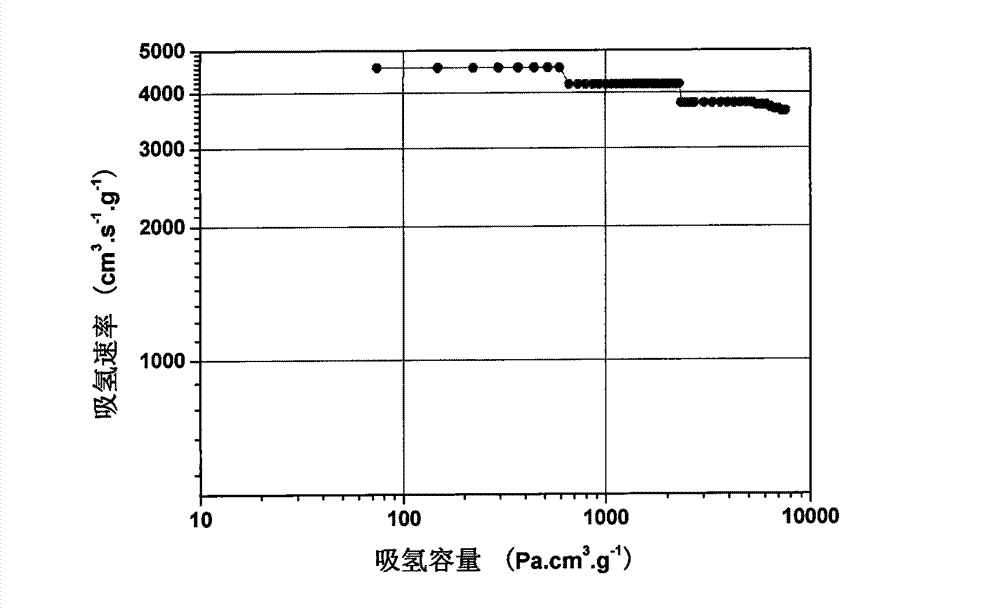

[0024] The raw materials are Ti (purity ≥ 99.5%), VFe (V content 80%), Mn (purity ≥ 98%), Y (purity ≥ 99.5%), and the alloy is based on Ti 30 (VFe) 46.5 mn 21 Y 2.5 Stoichiometric, prepared by ordinary medium-frequency induction vacuum melting method, the melted ingot is crushed, and ground into -100 mesh particle powder under the protection of argon. Take 0.32g and press it into 100 small pieces of Ф6×3mm size, take one of them randomly, and test the relationship between the hydrogen absorption rate and capacity of the alloy piece at room temperature according to GB / T 8763-1988. The test conditions are: the sample is better than 5×10 -3 Pa vacuum, activation at 450°C for 10 minutes, working temperature at 25°C, working pressure at 2.7×10 -4 Pa, test results such as image 3 As shown, Ti 30 (VFe) 46.5 mn 21 Y 2.5 alloy at 25°C for H 2 Hydrogen absorption rate S at 10 minutes 10 (cm 3 ·S -1 g -1 ) and hydrogen absorption capacity Q at 120 minutes 120 (cm 3 ·Pa·g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com