Lanthanum nickel alloy-expanded graphite solid compound adsorbent and preparation method thereof

A technology of expanded graphite and composite adsorption, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of easy deposition of lanthanum-nickel alloys and difficult composite adsorbents, etc., and achieve shortened heating and desorption time, axial The effect of improving the thermal conductivity and increasing the hydrogen absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Preparation of lanthanum-nickel alloy-expanded graphite solid composite adsorbent:

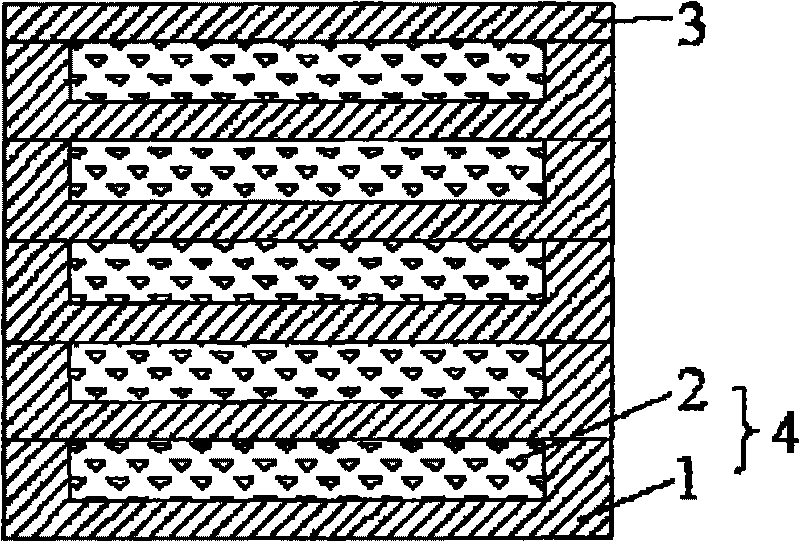

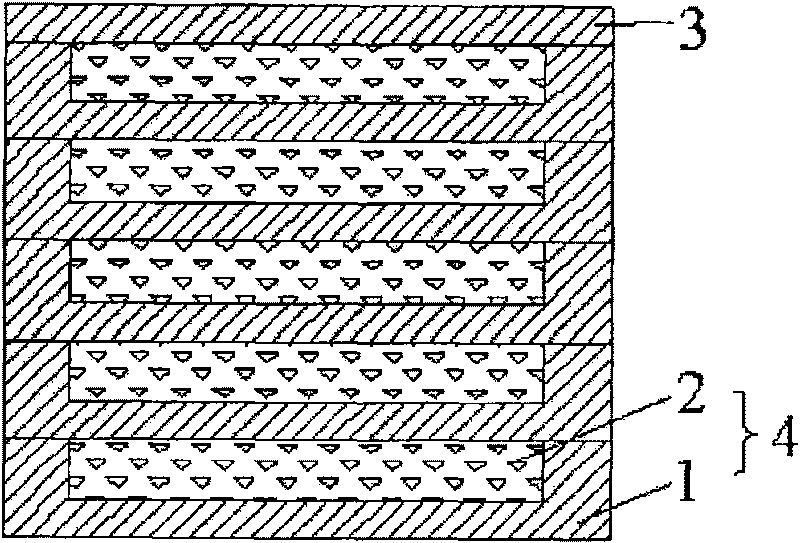

[0016] The production process of the whole solidified composite adsorbent is as follows: firstly, the production density is 5kg / m 3 1. A solidified expanded graphite concave matrix block (1) with a quality of 8g is cylindrical in shape, and the top face is recessed inwardly to form a cylindrical inner container; It is placed inside the ring of the solidified expanded graphite concave matrix block (1) to form a composite adsorbent unit (4). Then prepare another composite adsorbent unit according to the same method, and arrange the two composite adsorbent units sequentially from the bottom to the top in the order of the graphite concave matrix block-lanthanum-nickel alloy interlayer, and the final preparation density is 5kg / m 3 1. A solidified expanded graphite top layer matrix block (3) with a mass of 8g. The matrix block is cylindrical in shape, placed on the topmost lanthanum-nic...

Embodiment 2

[0023] 1. Preparation of lanthanum-nickel alloy-expanded graphite solid composite adsorbent:

[0024] The production process of the whole solidified composite adsorbent is as follows: firstly, the production density is 10kg / m 3 1. A solidified expanded graphite concave matrix block (1) with a quality of 8g is cylindrical in shape, and the top surface is sunken inward to form a cylindrical inner container; then 14.6g of lanthanum-nickel alloy is used as a lanthanum-nickel alloy interlayer (2) evenly Lay on the inside of the solidified expanded graphite concave matrix block (1) to form a composite adsorbent unit (4), and then prepare another composite adsorbent unit in the same way, and start from the bottom to the top according to graphite The sequence of concave matrix block-lanthanum-nickel alloy interlayer is to arrange two composite adsorbent units in sequence, and the final preparation density is 10kg / m 3 1. A solidified expanded graphite top layer matrix block (3) with a...

Embodiment 3

[0031] 1. Preparation of lanthanum-nickel alloy-expanded graphite solid composite adsorbent:

[0032] The production process of the whole solidified composite adsorbent is as follows: firstly, the production density is 15kg / m 3 1. A solidified expanded graphite concave matrix block (1) with a quality of 8g is cylindrical in shape, and the top surface is recessed inwardly to form a cylindrical inner container; It is placed inside the ring of the solidified expanded graphite concave matrix block (1) to form a composite adsorbent unit (4). Then prepare another composite adsorbent unit according to the same method, and arrange two composite adsorbent units sequentially from the bottom to the top in the order of graphite concave matrix block-lanthanum nickel alloy interlayer, and finally prepare a density of 15kg / m 3 1. A solidified expanded graphite top layer matrix block (3) with a mass of 8g. The matrix block is cylindrical in shape, placed on the topmost lanthanum-nickel all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com