Aircraft carbon-carbon composite brake disc and manufacturing method thereof

A carbon composite material and brake disc technology, applied in the direction of brake disc, mechanical equipment, brake type, etc., can solve the problems of limited application and development of carbon cloth lamination method, easy delamination, peeling, low material utilization rate, etc. Achieve the effect of favorable thermal protection, long service life and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

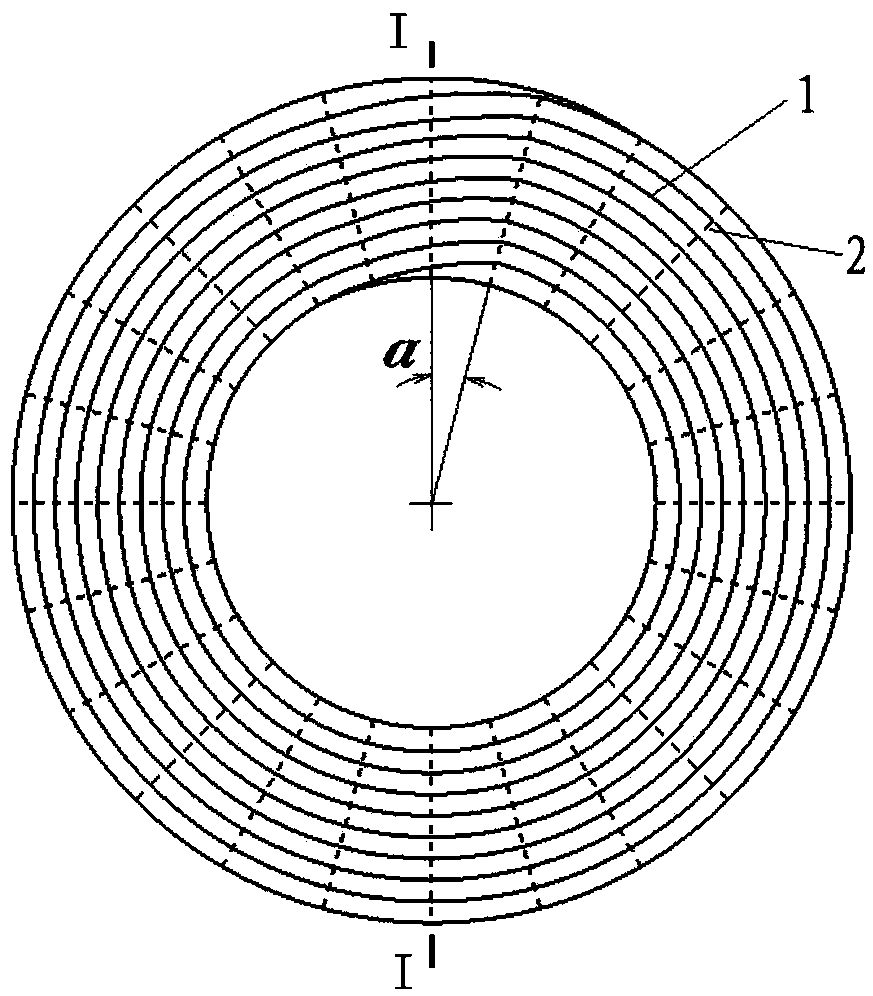

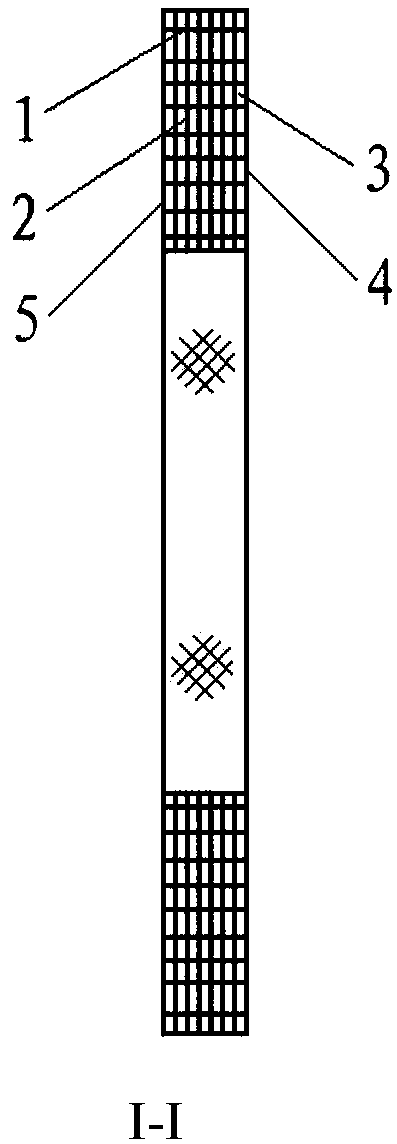

[0030] The invention relates to a carbon-carbon composite material brake disk for aircraft wheels. The carbon brake disc is composed of continuous circumferentially wound polyacrylonitrile carbon fiber cloth 1 , polyacrylonitrile carbon fiber wires 2 radially penetrating the polyacrylonitrile carbon fiber cloth layer and a carbon matrix 7 . The polyacrylonitrile carbon fiber wires 2 are evenly distributed along the circumferential direction and the thickness direction. The carbon brake disc has two sides both of which participate in friction, forming a first friction surface 5 and a second friction surface 6 . The first friction surface 5 and the second friction surface 6 of the carbon brake disc include side ends of a plurality of carbon fiber cloth roll layers and a carbon matrix 3 . As the surface wears, the carbon fiber threads that connect the carbon fiber cloth roll layers also become components of the friction surface. The carbonaceous matrix is resinous carbon obta...

Embodiment 2

[0048] The invention relates to a carbon-carbon composite material brake disk for aircraft wheels. The carbon brake disc is composed of continuous circumferentially wound polyacrylonitrile carbon fiber cloth and polyacrylonitrile carbon fiber felt 3, and the polyacrylonitrile carbon fiber line 2 radially passing through the polyacrylonitrile carbon fiber cloth and polyacrylonitrile carbon fiber felt layer The reinforcement is composed of a carbonaceous matrix. The polyacrylonitrile carbon fiber lines 2 are evenly distributed along the circumferential direction and the axial direction of the carbon brake disc. The friction surface of the carbon brake disc includes a plurality of carbon fiber cloths, the side ends of the felt roll layer and the carbon matrix, and the carbon brake disc composed of the plurality of carbon fiber cloths, the side ends of the felt roll layer and the carbon matrix The two sides form the first friction surface 5 and the second friction surface 6 of th...

Embodiment 3

[0066] This embodiment is a carbon-carbon composite material brake disc for an aircraft wheel. The carbon brake disc is composed of continuous circumferentially wound polyacrylonitrile carbon fiber mat 4 and reinforcements of polyacrylonitrile carbon fiber wires 2 that radially penetrate the polyacrylonitrile carbon fiber mat layer and are composited with a carbon matrix. The polyacrylonitrile carbon fiber wires 2 are evenly distributed along the circumferential direction and the thickness direction. The friction surface of the carbon brake disc includes side ends of multiple carbon fiber felt roll layers and a carbon matrix. As the surface wears, the carbon fiber threads that connect the carbon fiber felt rolls can also become components of the friction surface. The carbonaceous matrix is deposited carbon.

[0067] The aircraft carbon-carbon composite brake disc has two friction surfaces, which are the first friction surface 4 and the second friction surface 5 respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com