A kind of Zr-ti-cr-v multiphase hydrogen storage alloy and its preparation method

A zr-ti-cr-v, hydrogen storage alloy technology, applied in the field of hydrogen storage materials, can solve the problems that few can have both, achieve fast hydrogen absorption rate, increase lattice distortion, and improve hydrogen absorption kinetics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The design alloy composition is ZrTi 0.2 Cr 0.2 V 2 , The ratio is an atomic ratio; the purity of the Zr, Ti, Cr and V raw materials used in the experiment are 99.4%, 99.97%, 99.7% and 99.5% respectively.

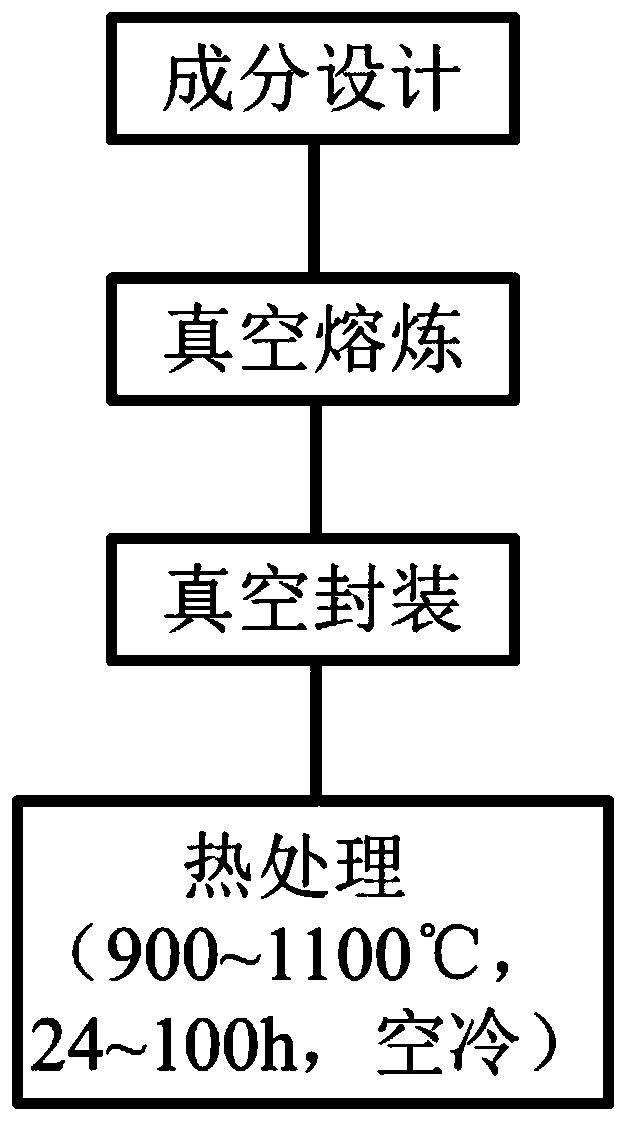

[0028] The preparation process of this embodiment is:

[0029] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.2:0.2:2 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 3 times;

[0030] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0031] Step 3, heat treatment. Put th...

Embodiment 2

[0034] The design alloy composition is ZrTi 0.4 Cr 0.1 V 1.8 , The ratio is an atomic ratio; the purity of the Zr, Ti, Cr and V raw materials used in the experiment are 99.4%, 99.97%, 99.7% and 99.5% respectively.

[0035] The preparation process of this embodiment is:

[0036] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.4:0.1:1.8 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 5 times;

[0037] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0038] Step 3, heat treatment. Pu...

Embodiment 3

[0041] The design alloy composition is ZrTi 0.6 Cr 0.2 V 1.9 , The ratio is an atomic ratio; the purity of the Zr, Ti and V raw materials used in the experiment are 99.4%, 99.97% and 99.5% respectively.

[0042] The preparation process of this embodiment is:

[0043] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.6:0.2:1.9 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 5 times;

[0044] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0045] Step 3, heat treatment. Put the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com