A kind of preparation method of aluminum alloy welding consumable ingot

A technology of aluminum alloy and welding consumables, which is applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of welding consumables weldability and joint performance reduction, thickness, and difficulty in eliminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

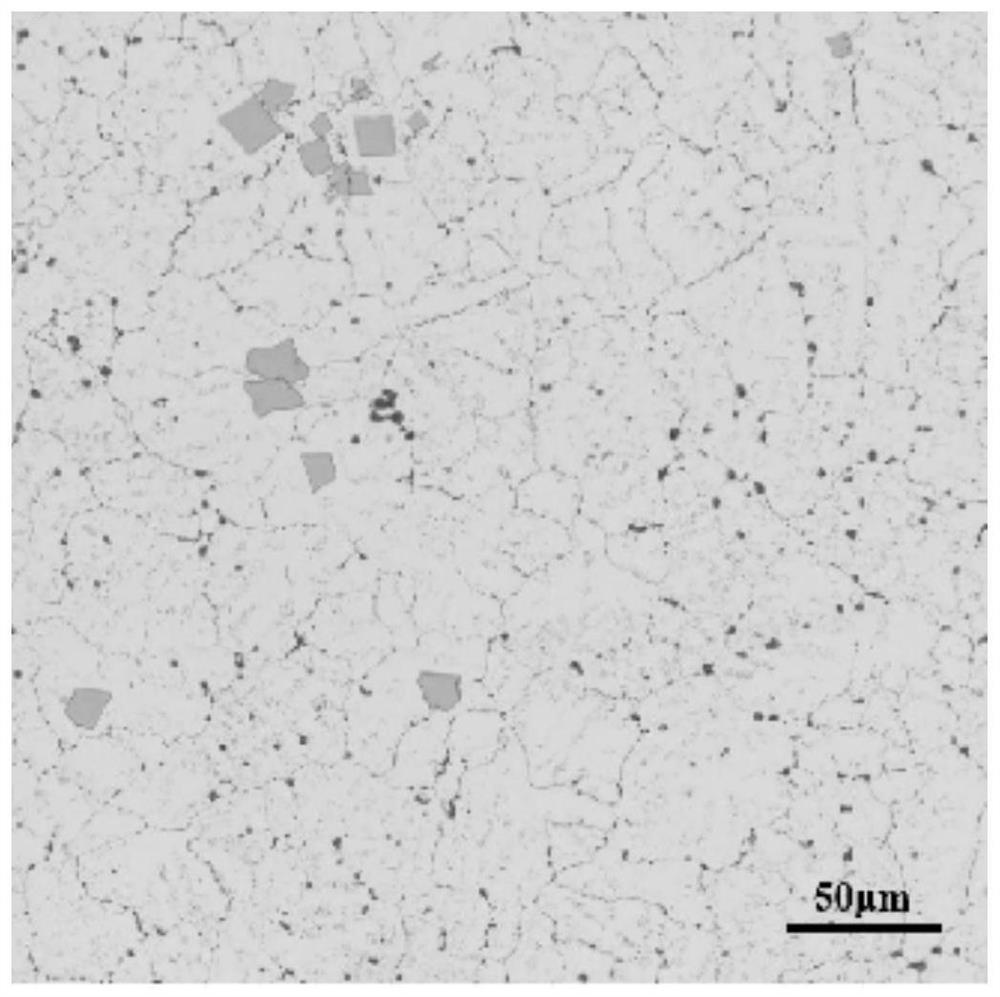

Image

Examples

Embodiment 1

[0029] The mass percentage of the aluminum alloy welding material in this example is Mg: 4.5%, Mn: 1%, Zn: 1.2%, Ti: 0.12%, Sc: 0.02%, Zr: 0.35%, Fe≤0.2%, Si≤0.15% , the balance being Al.

[0030] The ingot preparation process is as follows:

[0031] 1) Dosing according to the target ingredients, wherein Al purity ≥ 99.95%, Mg purity ≥ 99.98%, Zn purity ≥ 99.995%, Mn, Ti, Sc, Zr elements are respectively used Al-10% Mn, Al-10% Ti, Al -2% Sc, Al-5% Zr master alloy.

[0032]2) Use a resistance furnace for smelting, first put Al ingots and Al-10%Mn, Al-10%Ti intermediate alloys into the crucible, heat up to 680°C after all the alloys are melted, and use a titanium alloy bell jar to melt the Mg and Zn ingots Press into the bottom of the pool to melt and stir the melt until smooth.

[0033] 3) After continuing to heat up to 800°C, add Al-2%Sc and Al-5%Zr master alloys to the melt gradually to keep the melt temperature not lower than 800°C.

[0034] 4) After the master alloy is ...

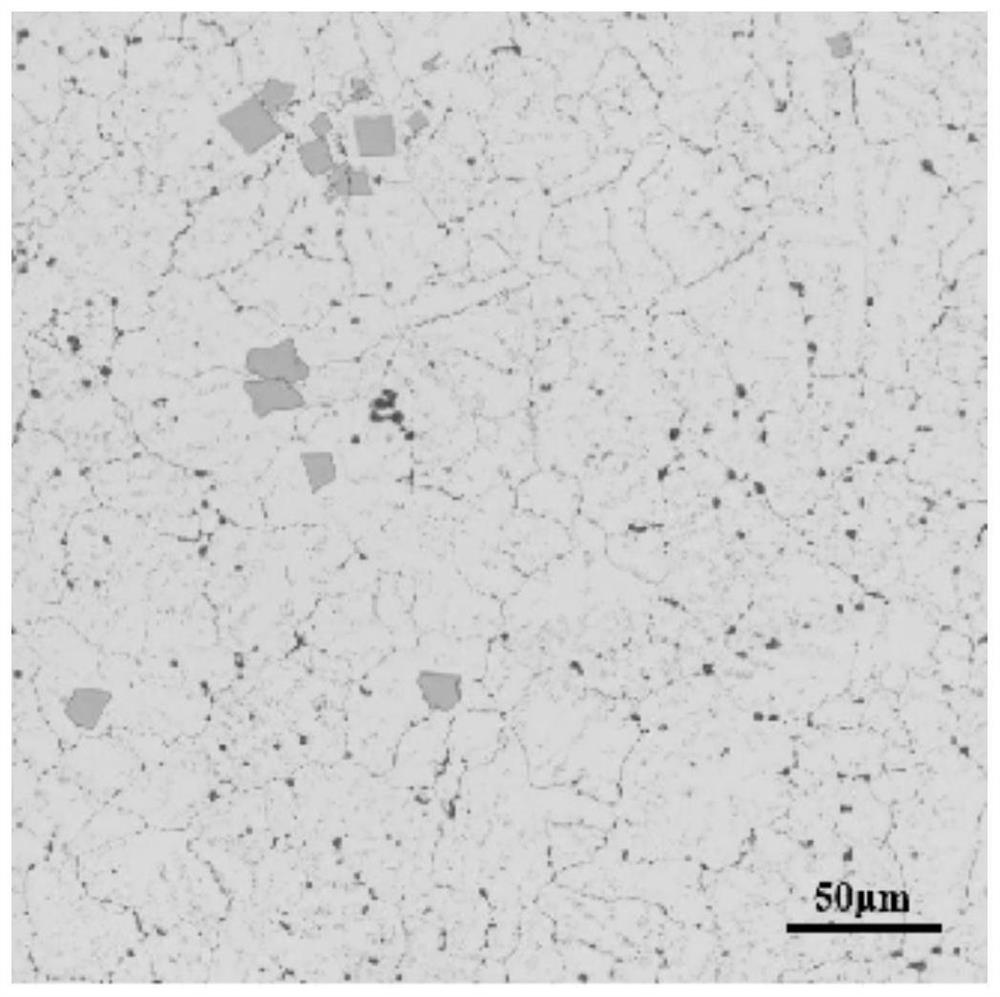

Embodiment 2

[0038] The mass percentage of the aluminum alloy welding material in this example is Mg: 5.5%, Mn: 0.8%, Zn: 0.8%, Ti: 0.08%, Sc: 0.2%, Zr: 0.2%, Fe≤0.2%, Si≤0.15% , the balance being Al.

[0039] The ingot preparation process is as follows:

[0040] 1) Dosing according to the target ingredients, wherein Al purity ≥ 99.95%, Mg purity ≥ 99.98%, Zn purity ≥ 99.995%, Mn, Ti, Sc, Zr elements are respectively used Al-5% Mn, Al-10% Ti, Al -1% Sc, Al-5% Zr master alloy.

[0041] 2) Use an intermediate frequency furnace for smelting, first put Al ingots and Al-5%Mn, Al-10%Ti master alloys into the crucible, heat up to 700°C after all the alloys are melted, and use a titanium alloy bell jar to press the Mg and Zn ingots Put it into the bottom of the molten pool to melt it, and stir the melt evenly.

[0042] 3) Continue to raise the temperature to 820°C, add Al-1%Sc and Al-5%Zr master alloys gradually to the melt, and keep the melt temperature not lower than 820°C.

[0043] 4) After...

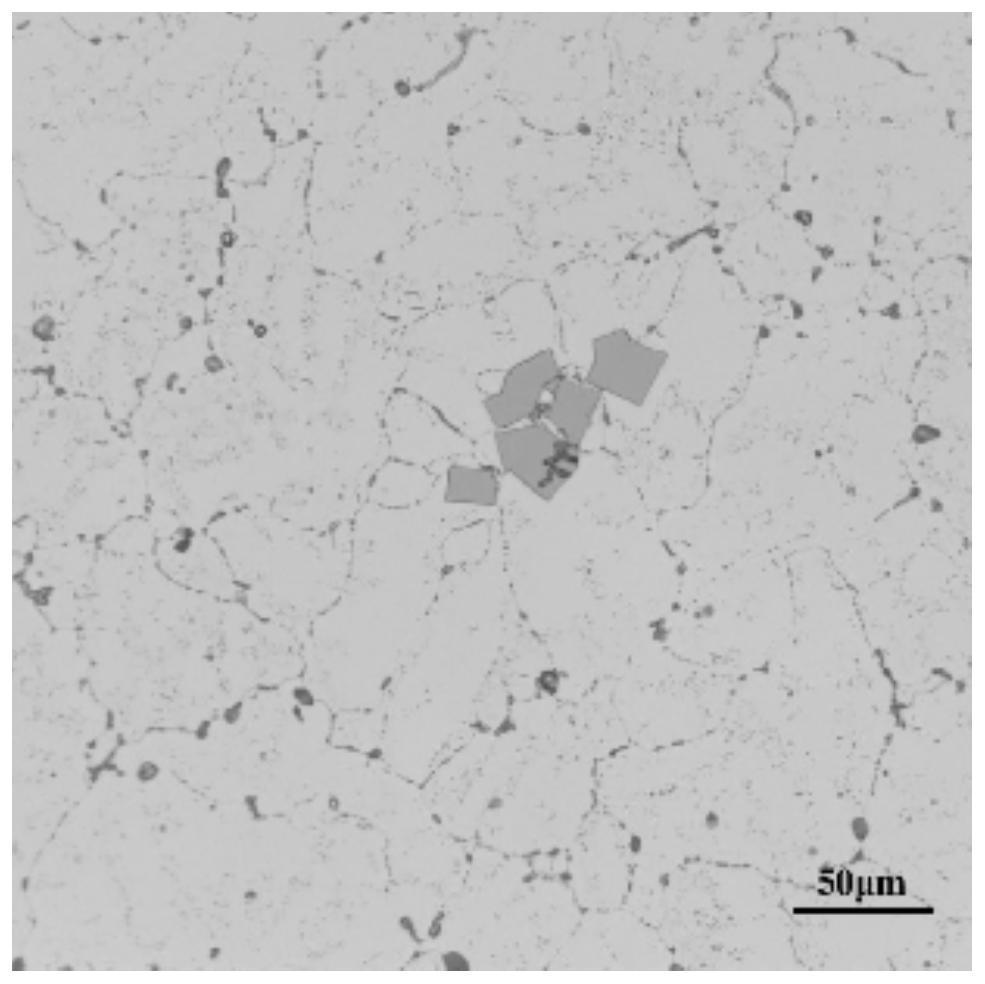

Embodiment 3

[0047] The mass percent of the aluminum alloy welding material in this example is: Mg: 7.5%, Mn: 0.1%, Zn: 0.2%, Ti: 0.01%, Sc: 0.6%, Zr: 0.02%, Fe≤0.2%, Si≤0.15 %, the balance is Al.

[0048] The ingot preparation process is as follows:

[0049] 1) Dosing according to the target ingredients, wherein Al purity ≥ 99.95%, Mg purity ≥ 99.98%, Zn purity ≥ 99.995%, Mn, Ti, Sc, Zr elements are respectively used Al-10% Mn, Al-5% Ti, Al -2% Sc, Al-5% Zr master alloy.

[0050] 2) Use an intermediate frequency furnace for smelting, first put Al ingots and Al-10%Mn, Al-5%Ti master alloys into the crucible, heat up to 720°C after all the alloys are melted, and use a titanium alloy bell jar to press the Mg and Zn ingots Put it into the bottom of the molten pool to melt it, and stir the melt evenly.

[0051] 3) Continue to raise the temperature to 850°C, add Al-2%Sc and Al-5%Zr master alloys gradually to the melt, and keep the melt temperature not lower than 850°C.

[0052] 4) After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com