Zirconium-vanadium based hydrogen storage alloy thin strip and preparation method thereof

A hydrogen storage alloy, zirconium vanadium-based technology, applied in chemical instruments and methods, hydrogen, reversible hydrogen absorption, etc., can solve the problems of poor hydrogen absorption kinetics, limited application range, high activation temperature, etc., and achieve excellent hydrogen absorption Kinetics, satisfying the effect of rapid hydrogen absorption and high hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

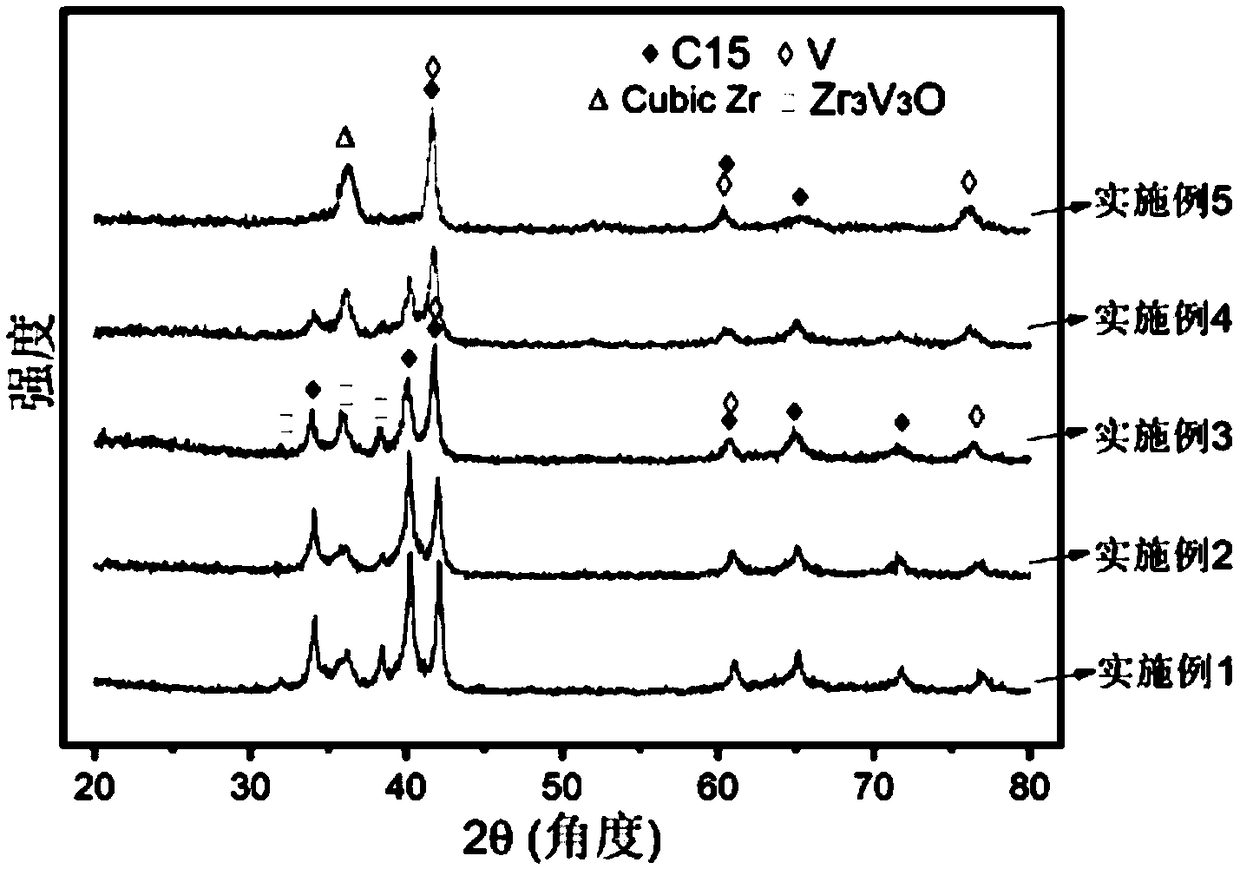

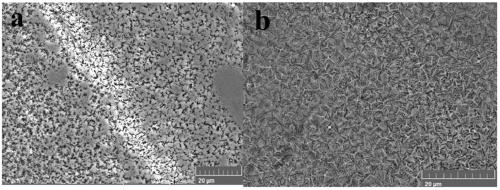

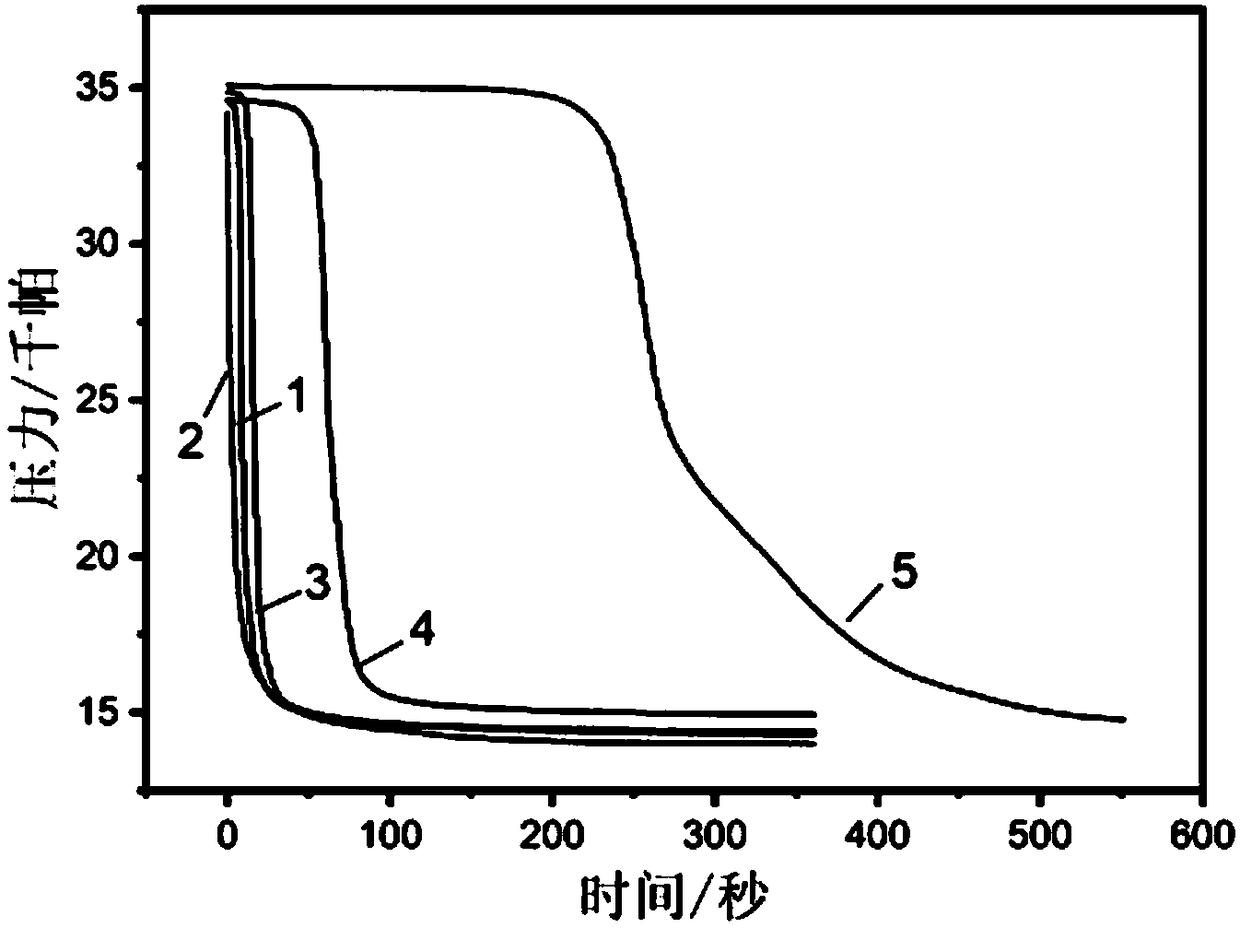

Embodiment 1

[0022] Step 1, smelting. The raw materials zirconium sponge, metal vanadium, titanium sponge and electrolytic manganese sheet (purity not less than 99.5%) according to the molecular formula ZrV 2 Ti 0.1 mn 0.1 The proportion of prepared, placed in a water-cooled copper crucible in a vacuum non-consumable arc melting furnace (Mn is placed at the bottom of the crucible). Vacuum the furnace to 6×10 -3 Below Pa, fill it with argon to 0.07MPa as a protective atmosphere. The tungsten pole in the vacuum non-consumable arc melting furnace is energized to start the arc, the current is gradually increased and the magnetic stirring function is turned on for 5 minutes for melting. The upper and lower surfaces of the cooled ingot are turned over, and the above-mentioned process of energizing arc ignition-stirring smelting-cooling and solidification is repeated three times to obtain an alloy ingot with uniform composition.

[0023] Step 2, preparing thin alloy strips. Part of the samp...

Embodiment 2

[0027] Step 1, smelting. The raw materials zirconium sponge, metal vanadium, titanium sponge and electrolytic manganese sheet (purity not less than 99.5%) according to the molecular formula ZrV 2 Ti 0.2 mn 0.1 The proportion of prepared, placed in a water-cooled copper crucible in a vacuum non-consumable arc melting furnace (Mn is placed at the bottom of the crucible). Vacuum the furnace to 6×10 -3 Below Pa, fill it with argon to 0.07MPa as a protective atmosphere. The tungsten pole in the vacuum non-consumable arc melting furnace is energized to start the arc, the current is gradually increased and the magnetic stirring function is turned on for 5 minutes for melting. The upper and lower surfaces of the cooled ingot are turned over, and the above-mentioned process of energizing arc ignition-stirring smelting-cooling and solidification is repeated three times to obtain an alloy ingot with uniform composition.

[0028] Step 2, preparing thin alloy strips. Part of the samp...

Embodiment 3

[0032] Step 1, smelting. The raw materials zirconium sponge, metal vanadium, titanium sponge and electrolytic manganese sheet (purity not less than 99.5%) according to the molecular formula ZrV 2 Ti 0.3 mn 0.1 The proportion of prepared, placed in a water-cooled copper crucible in a vacuum non-consumable arc melting furnace (Mn is placed at the bottom of the crucible). Vacuum the furnace to 6×10 -3 Below Pa, fill it with argon to 0.07MPa as a protective atmosphere. The tungsten pole in the vacuum non-consumable arc melting furnace is energized to start the arc, the current is gradually increased and the magnetic stirring function is turned on for 5 minutes for melting. The upper and lower surfaces of the cooled ingot are turned over, and the above-mentioned process of energizing arc ignition-stirring smelting-cooling and solidification is repeated three times to obtain an alloy ingot with uniform composition.

[0033] Step 2, preparing thin alloy strips. Part of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com