mg(bh 4 ) 2 -xcnts system hydrogen storage material and preparation method thereof

A hydrogen storage material and system technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, hydrogen, etc., can solve the problems of excessively stable thermodynamic properties, slow hydrogen release kinetics, and poor reversibility, etc. Achieve the effect of easy purchase, regular particle morphology and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

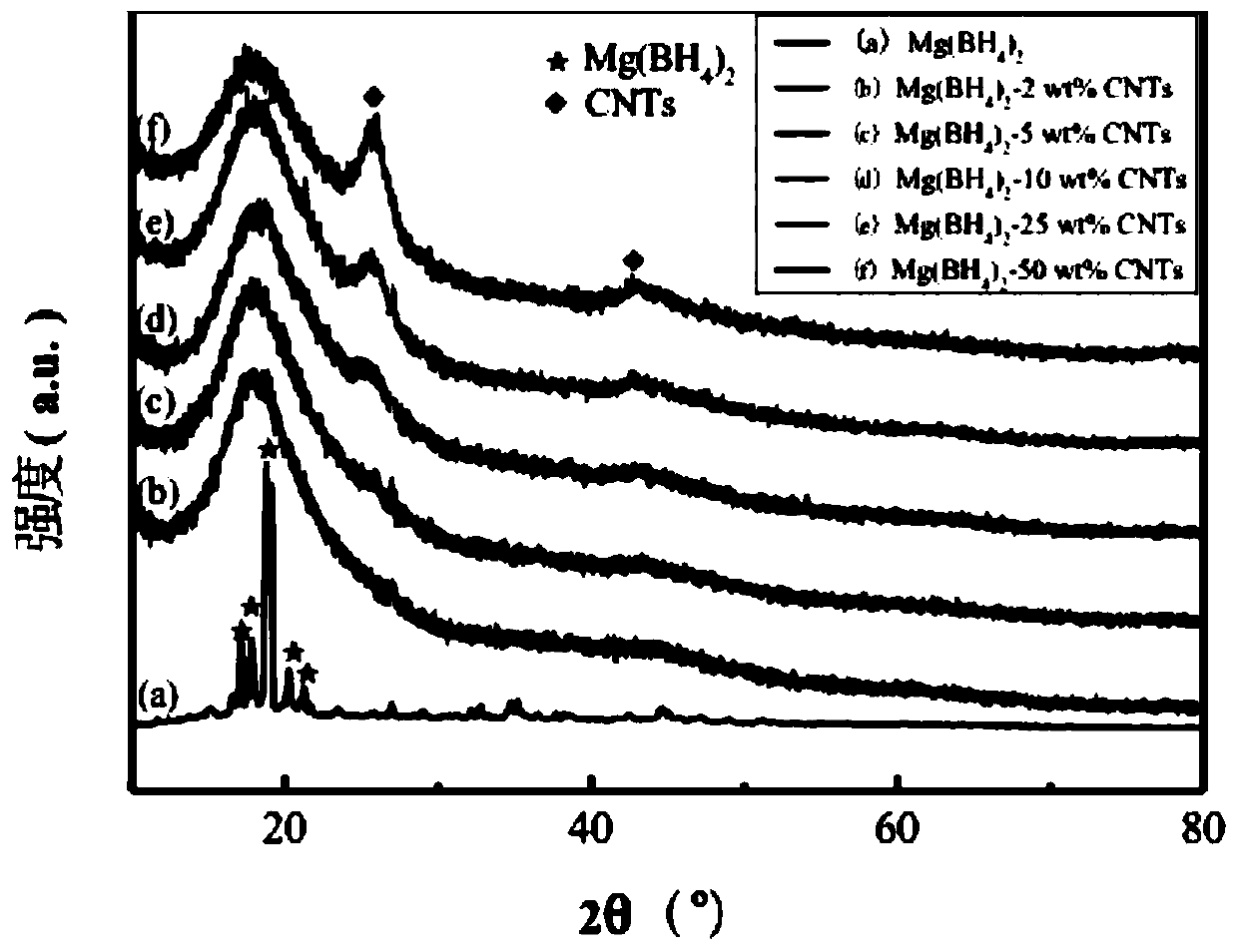

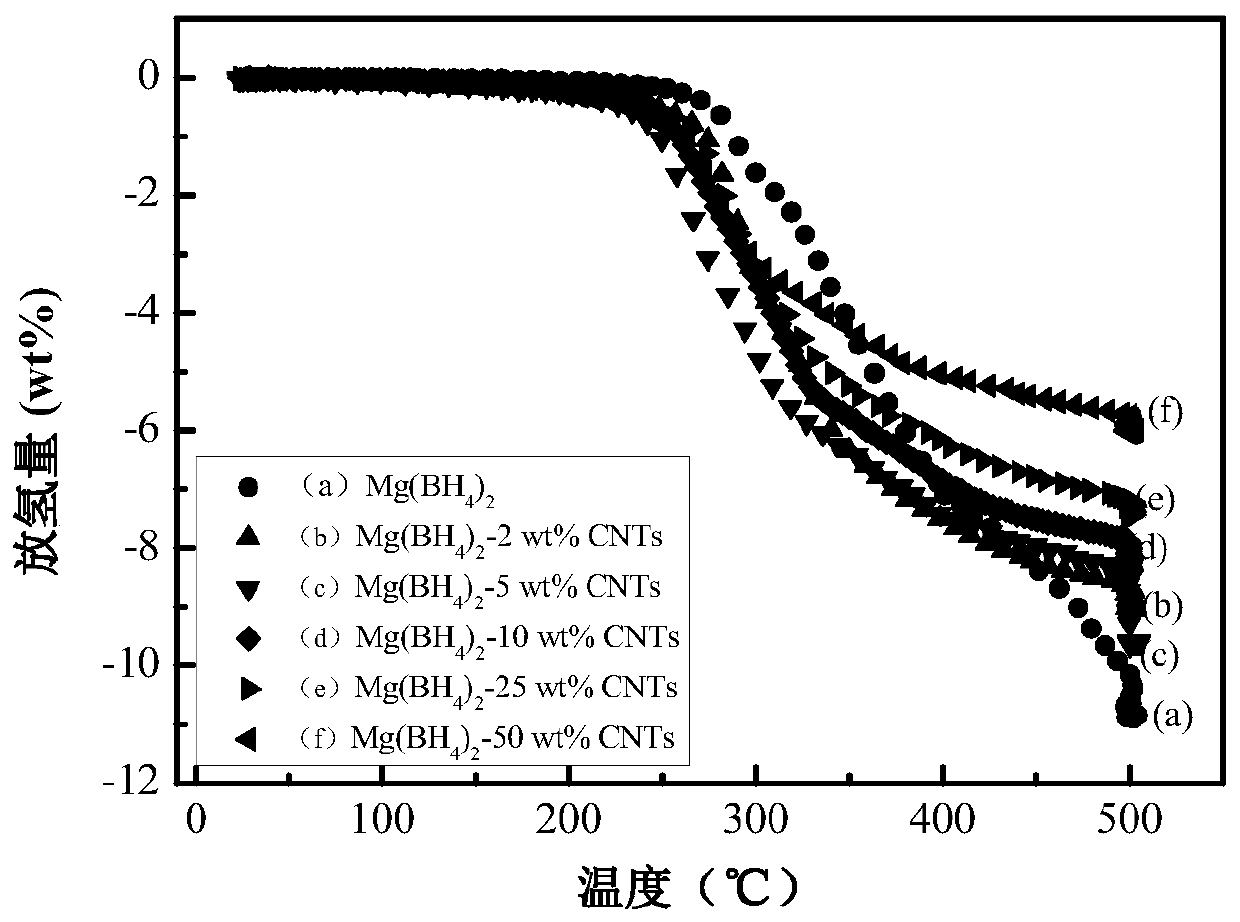

[0031] This embodiment includes the preparation of six hydrogen storage materials, and the specific preparation methods are as follows:

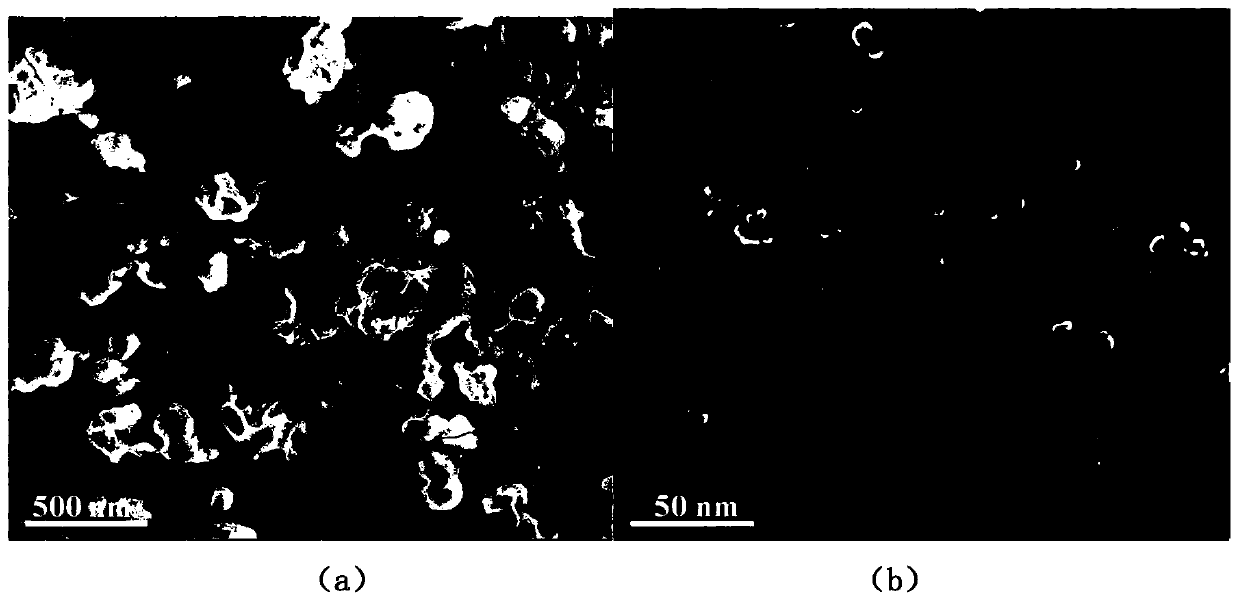

[0032] Prepare the mixed raw materials used in Example 1-1 to Example 1-V according to the raw materials in Table 1 and the relationship between the amount of additive CNTs, and then put six parts of mixed raw materials into 50ml ball mill jars for mechanical ball milling, wherein the balls The weight ratio to the mixed raw material is 40:1, filled with 3bar hydrogen (H 2 ) for protection, the ball milling speed is 350rpm, the ball milling time is 10h, and in the ball milling process, every ball milling 6min rests for 6min, to prevent the sample Mg(BH 4 ) 2 Decomposition occurs, and the obtained ball milling product is the hydrogen storage material. Among them, the ball milling product of Example 1-I is a hydrogen storage material without doping CNTs, that is, a control material, while Examples 1-II to 1-VI are hydrogen storage materials d...

Embodiment 2

[0042] The additive CNTs was added to the raw material Mg (BH 4 ) 2 After mixing, the hydrogen storage material Mg(BH 4 ) 2 -5wt% CNTs system sample, the whole ball milling process is charged with 3bar of hydrogen (H 2 ) for protection, and rest for 6 minutes every 6 minutes during the ball milling process, and the ball milling product is Mg(BH 4 ) 2 -5wt% CNTs hydrogen storage material.

[0043] In this example, the hydrogen storage material samples prepared by different ball milling processes after dehydrogenation were tested for reabsorption performance. The temperature is 300°C, the results are shown in Table 2 and Figure 6 . From Figure 6 It can be seen that the hydrogen storage material prepared in Example 2-1 completed the hydrogen absorption test within 2h, and the hydrogen absorption amount was 2.0wt%. Therefore, when the doping amount of CNTs was 5wt%, the Mg ( BH 4 ) 2 hydrogen reabsorption performance. In addition, the hydrogen desorption performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com