Method for preparing high-dispersibility zinc oxide granules and colloid thereof

A technology of zinc oxide particles and high dispersion, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, colloid chemistry, etc., can solve the problems of high cost and unfavorable mass production, and achieve uniform particle size and raw material The effect of low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get 2000 grams of deionized water, join in the reactor that reflux condenser is housed, add 20 grams of zinc nitrate hexahydrate, start the stirrer until all dissolve; Take by weighing 5.4 grams of sodium hydroxide and join in 2000 grams of deionized water, start Stirrer until completely dissolved; weigh 2 grams of lecithin and dissolve it in 1000 grams of deionized water, start the stirrer and heat up to 80°C until completely dissolved; the above solution zinc nitrate hexahydrate solution and sodium hydroxide were respectively mixed at 400ml / h Add it into the lecithin solution at a high speed, keep the reaction temperature at 80°C, and react for 2 hours after the addition; the reaction solution is filtered to obtain a white precipitate, which is washed 5 times with 200ml deionized water, and then washed with 50ml absolute ethanol for 2 hours. Second-rate. It was then dried at 100°C for 5 hours. That is, zinc oxide powder is obtained.

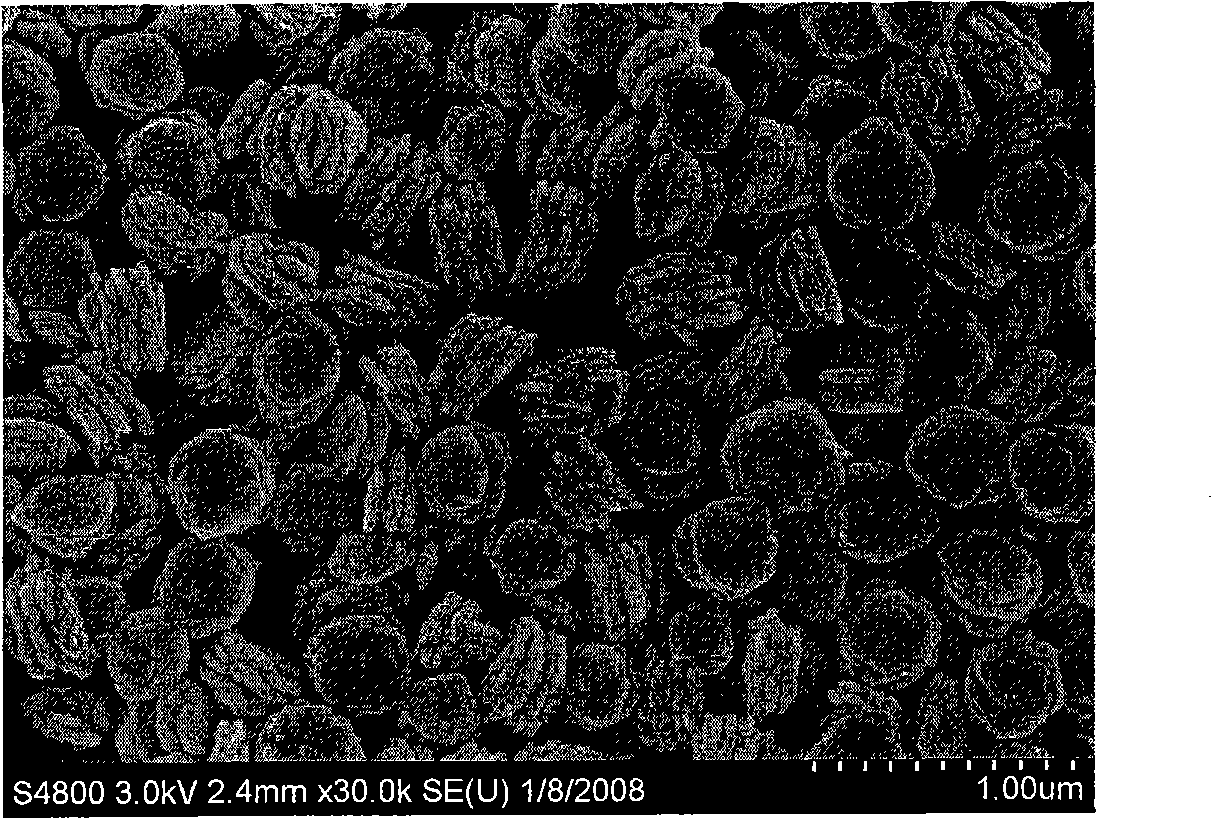

[0035] The scanning electron mi...

Embodiment 2

[0038] Get 2000 grams of deionized water, join in the reactor that reflux condenser is housed, add 60 grams of zinc nitrate hexahydrate, start the stirrer to dissolve completely; Take by weighing 16.2 grams of sodium hydroxide and join in 2000 grams of deionized water, start Stirrer until completely dissolved; weigh 2 grams of lecithin and dissolve it in 1000 grams of deionized water, start the stirrer and heat up to 80°C, until completely dissolved; the above solution zinc nitrate hexahydrate solution and sodium hydroxide were mixed at 400ml / h Add it into the lecithin solution at a high speed, keep the reaction temperature at 80°C, and react for 2 hours after the addition; the reaction solution is filtered to obtain a white precipitate, which is washed 5 times with 200ml of deionized water, and then washed with 50ml of absolute ethanol for 2 Second-rate. It was then dried at 100°C for 5 hours. That is, zinc oxide powder is obtained.

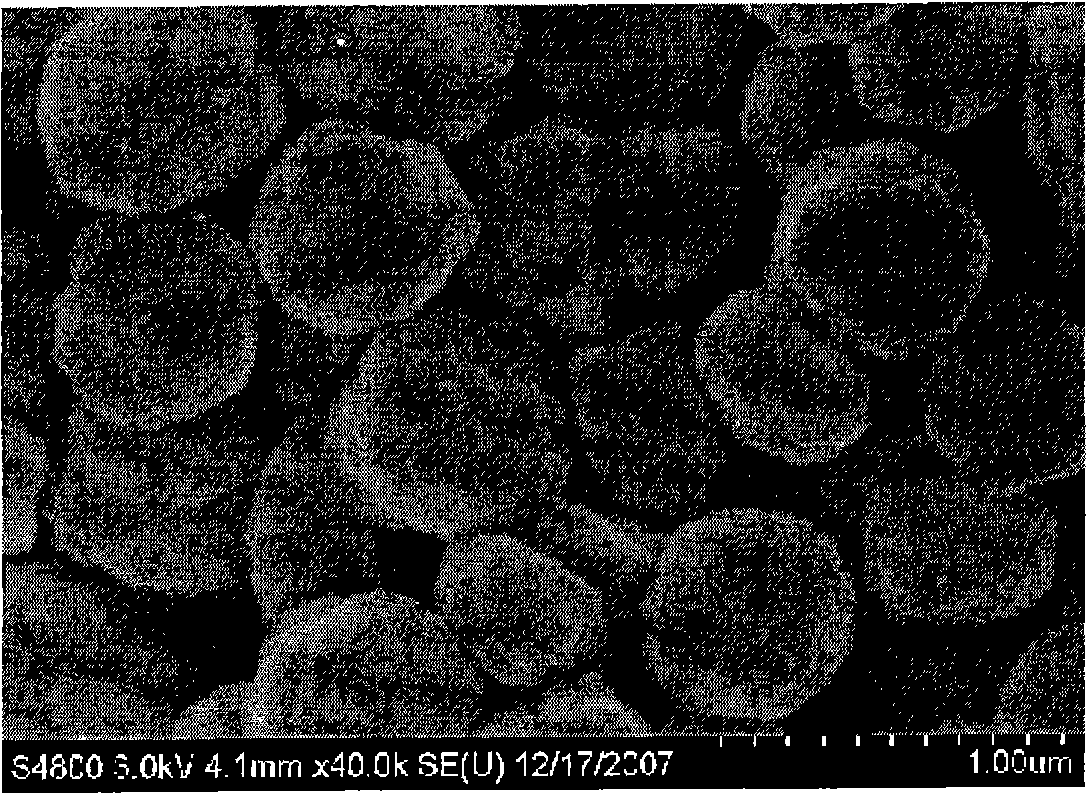

[0039] The particle size of the obtaine...

Embodiment 3

[0042]Get 2000 grams of deionized water, join in the reactor that reflux condenser is housed, add 20 grams of zinc nitrate hexahydrate, start the stirrer until all dissolve; Take 5.4 grams of sodium hydroxide and join in 2000 grams of deionized water, start Stirrer until completely dissolved; weigh 0.2 g of esterified modified starch and dissolve it in 1000 g of deionized water, start the stirrer and heat up to 80 ° C until completely dissolved; the above solution zinc nitrate hexahydrate solution and sodium hydroxide were respectively mixed with 400 ml Add it into the lecithin solution at a rate of / h, keep the reaction temperature at 80°C, and react for 2 hours after the addition; the reaction solution is filtered to obtain a white precipitate, which is washed 5 times with 200ml deionized water, and then separated with 50ml absolute ethanol. Wash 2 times. It was then dried at 100°C for 5 hours. That is, zinc oxide powder is obtained.

[0043] The particle size of the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com