Aluminum salt lithium adsorbent, and preparation method and application thereof

A lithium adsorption and aluminum salt technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of simple reaction process, high selectivity, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

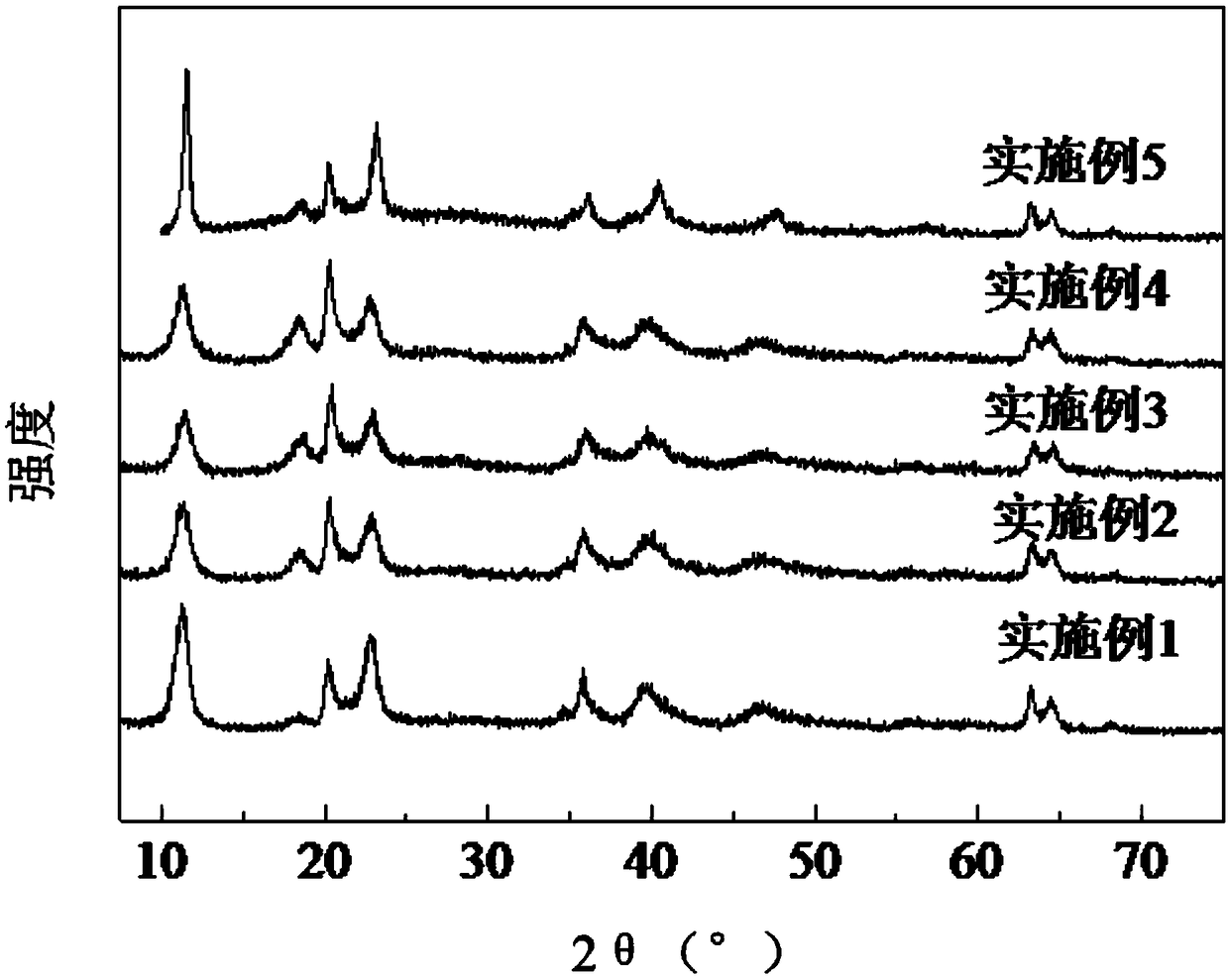

Embodiment 1

[0036] Weigh 24g AlCl 3 ·6H 2 O and 4.5g LiCl·H 2 O was dissolved in 30ml of deionized water, the Li / Al molar ratio was 1.5 / 2, the lithium solution concentration was 0.07mol / L, the aluminum solution concentration was 0.1mol / L, and the aluminum chloride and lithium chloride solutions were heated at 75°C. After ultrasonication for 60 minutes, mix evenly. Lithium-aluminum mixed solution and 6mol / L 50ml ammonia water are added dropwise to the reaction kettle at a rate of 15ml / min. The volume ratio of lithium-aluminum mixed solution to ammonia water is 1:1, and the stirring speed is 150rpm, the whole reaction is controlled by a circulating water bath at 90°C, and the pH value at the end of the dropwise addition is controlled to be 7. After the end, it is left to age for 24 hours at a temperature of 90°C. After aging, the reaction system was transferred to a 1L polytetrafluoroethylene hydrothermal kettle, and hydrothermally reacted at 160°C for 24h to obtain LiCl·aAl(OH) 3 ·nH 2...

Embodiment 2

[0043] Weigh 40g Al(NO 3 ) 3 9H 2 O and 4.8g LiNO 3 Dissolve in 50ml of deionized water, the Li / Al molar ratio is 1.3 / 2, the lithium solution concentration is 0.7mol / L, the aluminum solution concentration is 1.1mol / L, and the aluminum nitrate and lithium nitrate solutions are ultrasonicated at 65°C for 30min Mix evenly, the lithium-aluminum mixed solution is added dropwise in the 40ml sodium hydroxide solution of 8mol / L with the drop rate of 15ml / min, the volume ratio of lithium-aluminum mixed solution and alkaline solution is 1:1, and stirring speed is 150rpm, and the whole reaction consists of The circulating water bath was controlled at 90°C, and the pH value at the end of the dropwise addition was controlled to be 7. After the end, the mixture was aged at 90°C for 24 hours. After aging, the reaction system was transferred to a 1L polytetrafluoroethylene hydrothermal kettle, and hydrothermally reacted at 160°C for 24h to obtain LiCl·aAl(OH) 3 ·nH 2 The O precursor was ...

Embodiment 3

[0046] Weigh 34g Al 2 (SO 4 ) 3 and 4.4g Li 2 SO 4 Dissolve in 200ml of deionized water, the Li / Al molar ratio is 0.8 / 2, the lithium solution concentration is 0.40mol / L, the aluminum solution concentration is 1.0mol / L, and the aluminum sulfate and lithium sulfate solutions are ultrasonicated at 65°C for 30min Mix evenly, the lithium-aluminum mixed solution and 99.4ml sodium metaaluminate solution of 6mol / L are added dropwise to the reaction kettle at a rate of 15ml / min, the volume ratio of the lithium-aluminum mixed solution to the sodium metaaluminate solution is 2 : 1, the stirring speed is 150rpm, the whole reaction is carried out under the control of a circulating water bath at 50°C, the pH value at the end of the dropwise addition is controlled to be 5.5, and after the end, the temperature is left to stand for 24h under the condition of 50°C. After aging, the reaction system was transferred to a 1L polytetrafluoroethylene hydrothermal kettle, and hydrothermally reacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com