Waterborne acrylic macromolecular compound as well as preparation method and application thereof

A polymer compound and water-based acrylic technology, which can be used in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., and can solve the problems of high raw material costs and limited practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

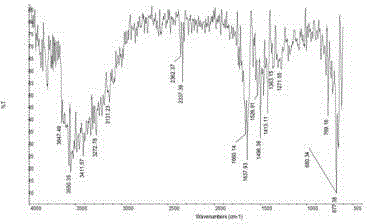

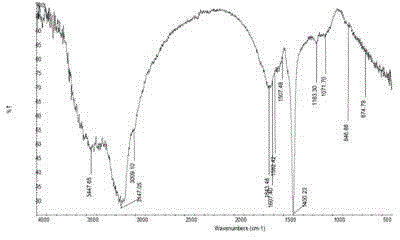

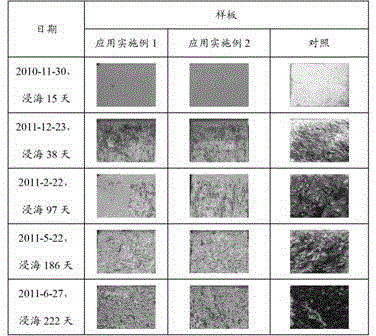

Image

Examples

Embodiment 1

[0131] Embodiment 1: Preparation of water-based acrylic polymer compound

[0132] The implementation steps of this embodiment are as follows:

[0133] A. According to the weight ratio of the total amount of monomers to water of 1, 10 parts by weight of acrylamide, 10 parts by weight of hydroxyethyl acrylate, 30 parts by weight of acryloyloxyethyltrimethylammonium chloride and 5 parts by weight of acrylic acid dissolved in water to obtain a monomer mixture solution; then,

[0134] B. Add 0.005% azobisisobutylamidine hydrochloride initiator to the monomer mixture solution obtained in step A to obtain a monomer mixture solution containing the initiator; then,

[0135] C. Under stirring conditions, add the monomer mixture solution containing the initiator obtained in step B to 110 parts by weight of water within 0.5 hours at a temperature of 50°C for copolymerization to obtain the water-based acrylic acid Polymer compound SBM-1 solution;

[0136] The solid content of the aqueou...

Embodiment 2

[0138] Embodiment 2: Preparation of water-based acrylic polymer compound

[0139] The implementation steps of this embodiment are as follows:

[0140] A. According to the weight ratio of the total amount of monomers to water of 10, 40 parts by weight of methylol acrylamide, 30 parts by weight of hydroxypropyl acrylate, and 70 parts by weight of methacryloxyethyl dimethyl benzyl chloride Ammonium chloride and 35 parts by weight of methacrylic acid are dissolved in water to obtain a monomer mixture solution; then,

[0141] B, adding 1% azobisisobutylimidazoline hydrochloride initiator in the monomer mixture solution obtained in step A in terms of the total weight of the above monomers, to obtain a monomer mixture solution containing the initiator; then ,

[0142] C. Under the condition of stirring, drop the monomer mixture solution containing the initiator obtained in step B into 1100 parts by weight of water within 4 hours at a temperature of 70°C to carry out copolymerizatio...

Embodiment 3

[0144] Embodiment 3: Preparation of water-based acrylic polymer compound

[0145] The implementation steps of this embodiment are as follows:

[0146] A. According to the weight ratio of the total amount of monomers to water of 4, 20 parts by weight of hydroxyethylacrylamide, 40 parts by weight of hydroxybutyl acrylate, and 45 parts by weight of 3-acrylamidopropyltrimethylammonium chloride Dissolve in water with 15 parts by weight of methacrylic acid, obtain a kind of monomer mixture solution; Then,

[0147] B, adding 1% azodicyanovaleric acid initiator in the monomer mixture solution obtained in step A in terms of the total weight of the above-mentioned monomers, to obtain a monomer mixture solution containing the initiator; then,

[0148] C, under the condition of stirring, the monomer mixture solution containing the initiator obtained in step B is added dropwise to 520 parts by weight in 15% ethanol aqueous solution by weight to carry out copolymerization reaction at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com