Preparation method of Mn<4+> doped fluoride fluorescent powder material and method for surface modification of Mn<4+> doped fluoride fluorescent powder material

A fluoride and phosphor technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of unfavorable white LED application, instability, and large particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

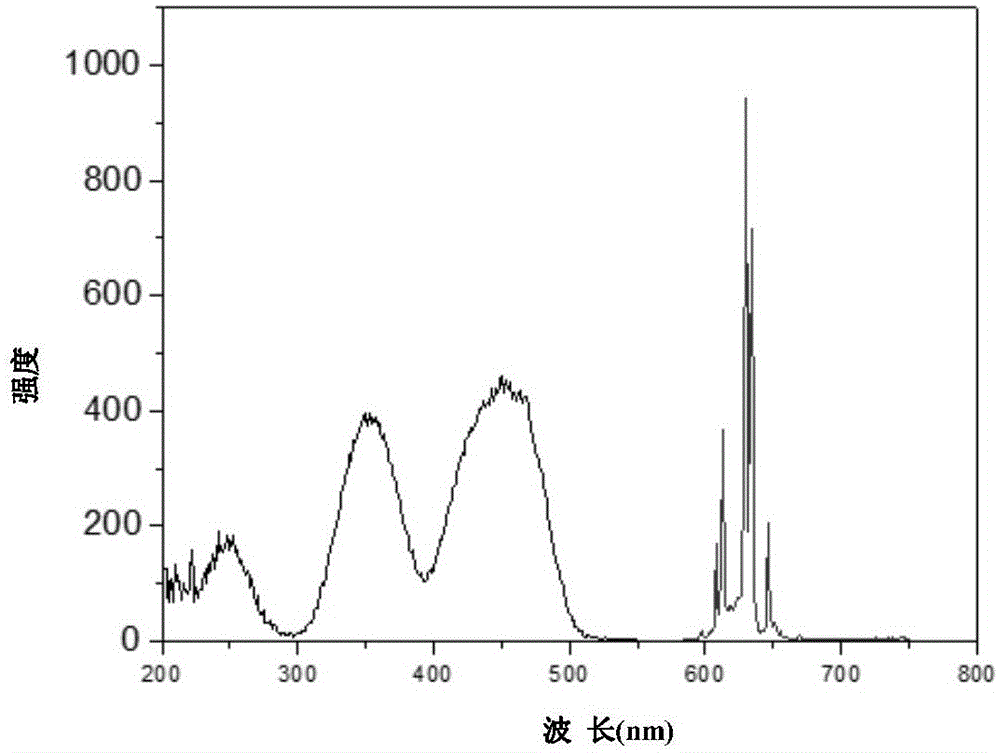

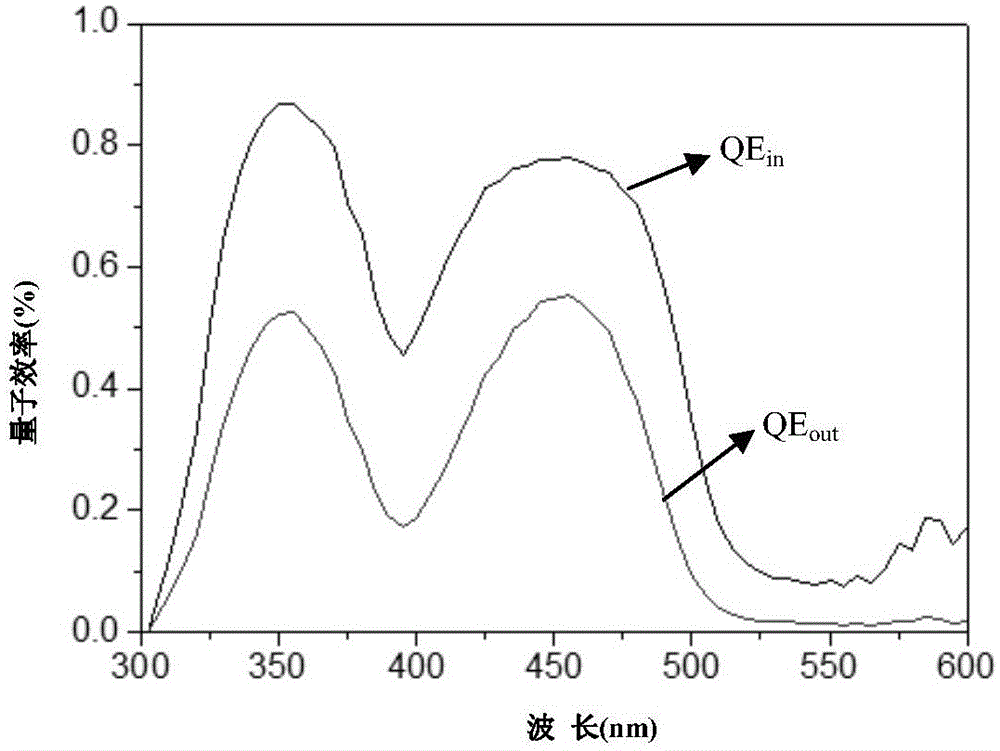

[0039] In the preparation method of the present invention, by adjusting the molar ratio of the substances of each element, mainly the luminescence center Mn 4+ The doping concentration can increase the luminous intensity and internal and external quantum efficiency.

[0040] Due to these manganese (Mn 4+ ) doped fluoride red phosphors are sensitive to moisture and will degrade in a high temperature, high humidity environment, causing the brightness of these phosphor materials to decrease significantly over time. In order to prolong the light emission of the LED, the present invention coats the surface of the prepared fluoride red fluorescent powder particles with organic or inorganic materials, so that it has a protective function against moisture.

[0041] The present invention is to the prepared manganese (Mn 4+ ) doped fluoride red phosphor powder was coated with inorganic materials, and its surface was Al 2 o 3 Coating: the prepared A 2 MF 6 :Mn 4+ The crystal powde...

Embodiment 1

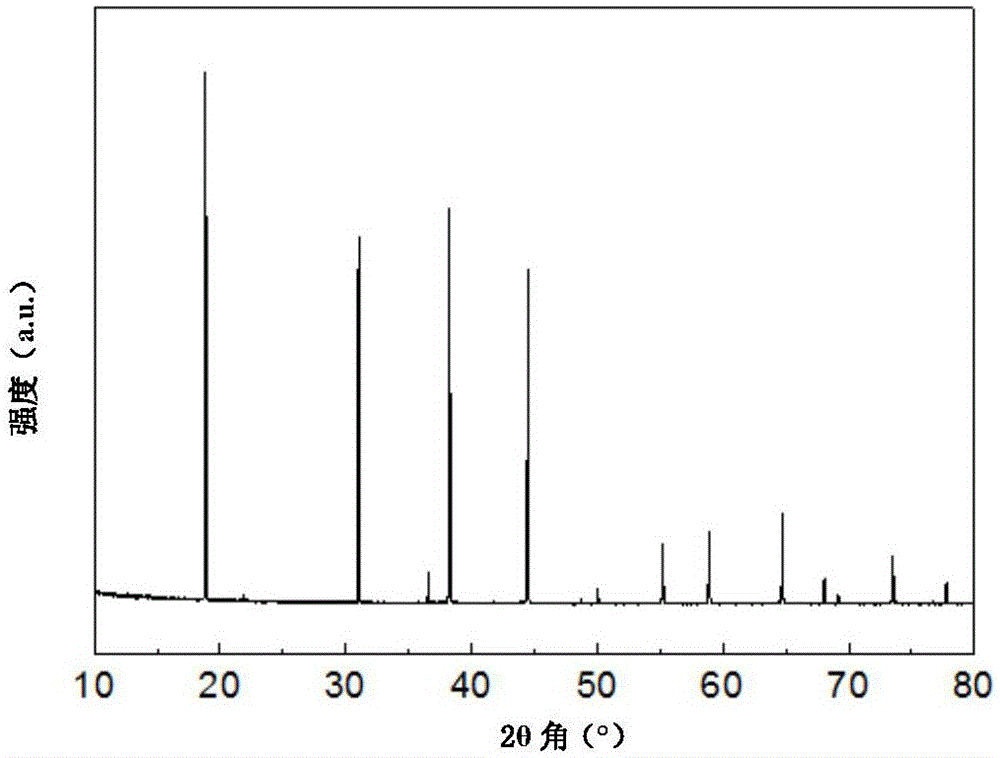

[0048] Preparation of K with small particle size and high brightness 2 SiF 6 :Mn 4+ Fluoride red phosphor

[0049] Weigh 30gKHF 2 , dissolved in 100ml of 40wt% hydrofluoric acid, added 1.5gKMnO 4 , after all dissolved, place the polytetrafluoroethylene beaker in an ice-salt water bath, cool to below 20°C, add 30wt% H2O dropwise after the temperature reaches the requirement 2 o 2 , stop dropping until the purple solution turns golden yellow. During the dropwise addition, a precipitate precipitates out of the solution, then filter, wash with acetone three times, put the filter cake in an oven at 100°C for 2 hours, and take out the dry filter cake after the drying is complete. Grind and crush to get golden yellow potassium hexafluoromanganate (K 2 MnF 6 ).

[0050] Weigh 10ml35wt%H 2 SiF 6 Add 60ml of 49wt% hydrofluoric acid, then add 0.6g of synthetic K 2 MnF 6 As the first solution, 4.9gKHF 2 Dissolve in 15ml of 49wt% hydrofluoric acid as the second solution. After...

Embodiment 2

[0053] Preparation of High Stability K by Atomic Layer Deposition Technology 2 SiF 6 :Mn 4+

[0054] Atomic layer deposition (ALD), also known as atomic layer deposition or atomic layer epitaxy, is a method that can coat substances layer by layer in the form of a single atomic film on the surface of a substrate.

[0055] K will be produced 2 SiF 6 :Mn 4+ The crystal powder is placed in the Φ5mm special sample cell, and then the sample cell is placed in the sample deposition chamber of the ALD deposition equipment, the window temperature is set to 185°C, the airflow speed and flow rate are controlled, and the aluminum oxide material is deposited for 48 hours. The deposition thickness is 20-30nm, the prepared sample number is KSFM-2.

[0056] The quantum efficiency was measured by Hitachi F-7000 fluorescence spectrometer, and the internal quantum efficiency was confirmed to be 75, the external quantum efficiency was 54%, and the chromaticity parameters (as shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com